Biodiversity Conservation and Nature Positive

Basic Policy

Recognizing that natural capital and biodiversity are foundational for realizing a sustainable society, the JFE Group has endorsed the Declaration of Biodiversity by Keidanren and Action Policy and conducts business in harmony with nature across the world. We particularly recognize biodiversity conservation as a key challenge and conduct assessments to minimize the ecological impact associated with our business activities. We are also engaged in activities that contribute to biodiversity conservation and nature positive at our own production sites, construction sites, and their surrounding areas, and at suppliers. Our initiatives include cooperating with the community to monitor biodiversity and carry out preservation activities around the steelworks, the key facilities for our business, and in surrounding areas. We are also involved in developing iron and steelmaking slag products that can help restore the marine environment. Furthermore, beyond our business operations, we launched a joint research program with a local government and conduct environmental education for local communities.

Our core steelmaking business uses large quantities of fresh water for cooling and cleansing products and facilities. For this reason, the efficient use of water resources with due consideration to the source of the water and stakeholders in the area is a key challenge. While we have always implemented countermeasures against meteorological disasters such as droughts and floods at our manufacturing sites in Japan, we are further reinforcing them in anticipation of the increased frequency and severity of weather events associated with climate change by securing alternative means and raising the height of embankments. We also seek to identify water-related risks throughout our business sites and supply chain in Japan and overseas, such as the risk of drought at the source of water intake and pollution at the point of discharge. In areas under water stress, we will respond appropriately through dialogue with stakeholders.

Basic Approach

The JFE Group has established a basic policy to promote initiatives for biodiversity conservation and nature positive.

Guided by our corporate philosophy of contributing to society with the world’s most innovative technology, the JFE Group recognizes biodiversity conservation and nature positive as essential for realizing a sustainable society, and established the following policies to guide its activities:

- Deepen recognition that our business activities depend on and impact biodiversity and natural capital and promote activities to mitigate risks.

- Promote the development of processes, products, and technologies that contribute to biodiversity conservation and nature positive.

- Collaborate with stakeholders such as local communities and supply chains and promote biodiversity conservation and nature positive efforts through diverse approaches, including integration with carbon neutrality and the circular economy.

- Foster awareness of biodiversity through employees’ proactive initiatives and educational activities.

- Disclose initiatives for biodiversity conservation and nature positive and broadly share them with society.

Endorsing and Participating in External Initiatives

As a member of the Keidanren Committee on Nature Conservation, the JFE Group endorses the Declaration of Biodiversity by Keidanren and Action Policy and actively engages in the conservation of nature and biodiversity.

The Group took part in the Business for GBF Project, launched by the Ministry of the Environment and Keidanren Committee on Nature Conservation. We are now registered as an NPE Partner in developing its Nature Positive Economy Promotion Platform (NPE Platform).

JFE Holdings has also joined the 30 by 30 Alliance for Biodiversity, launched by the Ministry of the Environment, business associations, nature conservation groups, and other organizations. This alliance is committed to effectively protecting at least 30% of Japan’s land and sea as healthy ecosystems toward the Nature Positive goal of halting and reversing biodiversity loss by 2030. JFE will contribute to the conservation of biodiversity by carrying out various activities, including the conservation of its biotopes.

For further details on external initiatives, please refer to:

In addition, JFE Holdings has endorsed the disclosure recommendations published by the Taskforce on Nature-related Financial Disclosures (TNFD), joined the TNFD Forum, and registered as a TNFD Adopter. Going forward, we will appropriately disclose information about the impacts of our business activities on the natural environment and biodiversity in line with the TNFD framework.

Governance

The JFE Group’s initiatives for biodiversity conservation and nature positive are supervised and guided by the JFE Group Sustainability Council, chaired by the president of JFE Holdings. A cross-group JFE Group Environmental Committee has been established to discuss matters such as targets, progress checks, and improving overall Group performance. Particularly key issues and indicators are supervised through deliberations of the Board of Directors.

Strategy

Evaluation of the Relationship between Business Activities and Natural Capital (Evaluation in Line with the LEAP Approach)

The JFE Group pilot tested the LEAP approach in line with the recommendations of the Taskforce on Nature-related Financial Decisions (TNFD). In FY2023, we conducted a trial evaluation focusing on the steel business. In FY2024, we expanded the scope within the steel business for more detailed examinations and conducted evaluations for the engineering business.

Process

Steel Business

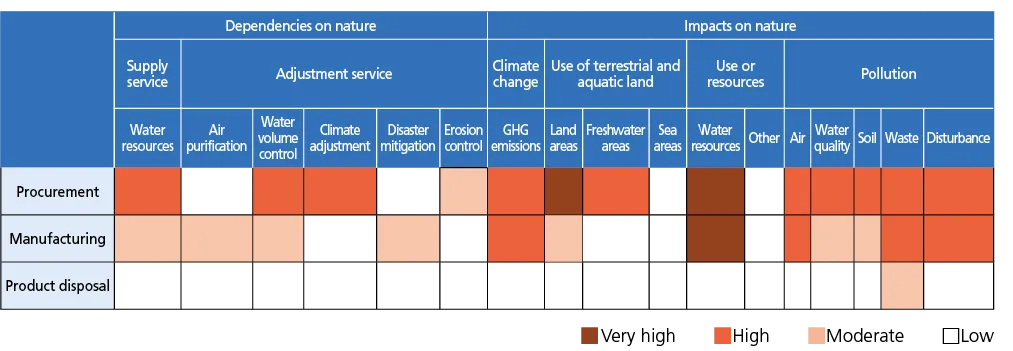

Specific Categories of Findings on the Dependencies and Impacts on Nature (Evaluate)

Regarding the dependencies and impacts of our steel business on nature, we reviewed the findings under the categories of manufacturing at our production sites and procurement from our upstream supply chain at iron ore and coking coal mining sites. Our procurement and manufacturing operations depend on natural resources, particularly related to water supply, the control of water volume, and climate adjustments. Meanwhile, our manufacturing operations impact nature through GHG emissions and pollution. The iron ore and coking coal mining conducted upstream in our supply chain also affect nature through land use, water resource use, GHG emissions, and pollution.

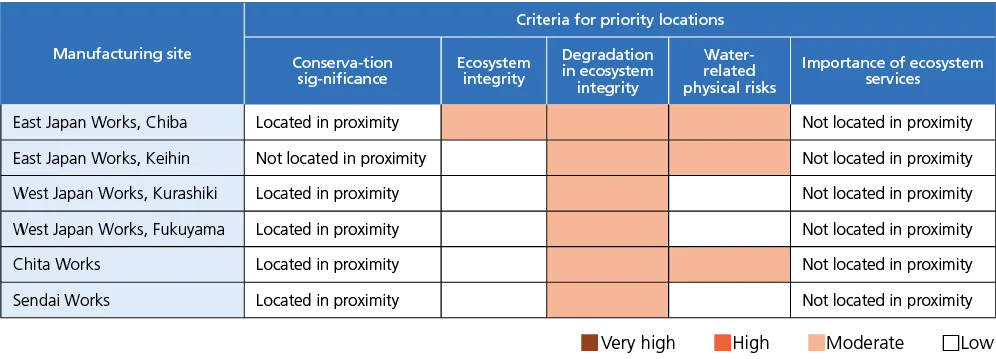

Assessment of Leading Manufacturing Sites (Locate)

Our assessment of leading major manufacturing sites in line with the five criteria defined by the TNFD for priority areas found that areas of high conservation significance, including key biodiversity areas (KBAs), exist in the surrounding regions. We also conducted similar assessments for production sites of JFE Steel’s domestic Group companies, evaluated the surrounding natural environment, and confirmed the results.

In addition, the JFE Shoji Group conducted similar assessments at 48 processing sites operated by 38 companies (24 sites at 18 companies in Japan and 24 sites at 20 companies overseas). In Japan, six sites were found to be adjacent to protected areas or KBAs of high conservation significance. Overseas, sites in eight countries were found to face water risks, and in one country, a site was identified as being adjacent to indigenous peoples or local communities. These sites have been recognized as priorities for future evaluation and responses.

- *Assessment based on the five criteria was performed using the following indicators and tools.

• Conservation significance: Assessed with IBAT, the proximity (within a 5-km radius) to areas of conservation significance, for example, protected areas and KBAs

• Ecosystem integrity: Assessed based on the Biodiversity Intactness Index provided by Natural History Museum

• Rapid degradation in ecosystem integrity: Assessed based on the Pressure on Biodiversity indicator provided by WWF Biodiversity Risk Filter to measure at degree of influence on nature

• Water-related physical risks: Assessed based on the Baseline Water Stress, Riverine Flood Risk, and Coastal Flood Risk indicators through the use of Aqueduct

Assessment of Raw Material Suppliers (Locate)

We located the interfaces of our major iron ore and coking coal suppliers in natural settings and assessed the state of nature at those sites (procurement volume of roughly 70%; 8 iron ore mines and 14 coking coal mines). Iron ore is procured from countries including Australia and Brazil. The assessment revealed that procurement mines in Australia are exposed to high water stress, making responses to water-related risks important. Although procurement volumes are relatively small, some mines in Brazil were found to be located near areas of conservation significance.

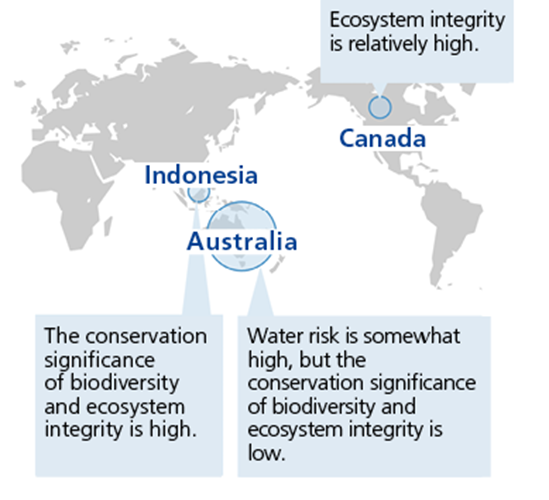

Our coking coal suppliers are mining in Australia, Canada, and Indonesia. The assessment revealed that procurement mines in Australia face relatively low levels of various risks. On the other hand, some mines in Canada and Indonesia were found to be located in regions with high ecosystem integrity.

Iron ore (supplier countries and procurement ratios)

Coking coal (supplier countries and procurement ratios)

Reviewing Nature-Related Risks and Opportunities (Assess/Prepare)

Following the above evaluation of dependencies and impacts, we organized the currently assumed nature-related risks and opportunities. The risks, some of which are recognized in our climate change scenario analysis, include physical risks that could be materialized due to a water shortage or natural disasters and potentially trigger a decrease in production at our manufacturing sites or a lack of procurement from suppliers. Additionally, transition risks may arise if regulations concerning protected areas and pollution are tightened. On the other hand, opportunities were identified in the form of increased demand and development potential for environmentally friendly products, processes, and technologies, as well as environmental materials that contribute to resource circulation.

Meanwhile, we confirmed that JFE Steel's major iron ore and coking coal suppliers have conducted assessments concerning water resources and ecosystem and have publicly disclosed how to respond to their detected risks. We will continue to monitor the status of their response efforts as part of our supply chain management. We will also encourage more of our suppliers to adopt and observe the JFE Steel Procurement Guidelines.

As for our own material risks and opportunities, we will maintain the current measures in place and, while enhancing our assessment, we will keep a close watch on whether additional measures are necessary.

Nature-Related Risks and Opportunities in Direct Operations

| Category | Item | Impact | Magnitude | Likelihood | Timeframe | Response | ||

|---|---|---|---|---|---|---|---|---|

| Direct operations | Physical risk | Acute | Intensification of extreme weather | Suspension of operations due to infrastructure damage caused by the increased frequency and severity of natural disasters | Large | Low | Medium term |

Reinforcement of drainage facilities at steelworks and plants

|

| Chronic | Water shortages and ecosystem degradation | Suspension of operations due to ecosystem degradation, such as water depletion | Large | Low | Long term |

Reduced water intake and discharge by recycling water

|

||

| Transition risk | Policies and regulations | Stricter regulations toward nature positive | Increased compliance costs from tighter regulations on water use and pollution affecting ecosystems around business sites (terrestrial and aquatic) | Medium | Low | Long term |

Implementation of the following measures with the goal of Zero Major Environmental and Disaster Accidents

|

|

| Reputation | Impact on surrounding ecosystems | Increased costs from adverse impacts on local ecosystems (terrestrial and aquatic) through water use or pollution, and revenue decline due to loss of trust | Medium | Low | Long term | |||

| Opportunity | Services, markets | Ecosystem restoration and environmental load reduction through steel and slag products | Increased demand for products contributing to nature positivity and reducing environmental load | Medium | High | Short term |

Expansion of supply of products that contribute to biodiversity, nature positivity, and environmental load reduction, and collaboration with municipalities and other companies

|

|

| Products and services | Growing demand for resource-circulating products | Higher sales by expanding lineup of resource-circulating products | Medium | High | Medium term |

Expand lineup of environmental products supporting resource circulation

|

||

| Nature preservation and restoration | Biodiversity conservation at factories | Enhanced reputation among stakeholders, including local residents, by promoting initiatives on Company premises in response to growing public interest in nature and biodiversity conservation | Low | Medium | Medium term |

Biodiversity conservation initiatives on Company premises, mainly at the Chita Works

|

||

| Upstream | Physical risk | Acute | Intensification of extreme weather | Instability of raw material procurement and increased procurement costs due to increased frequency and severity of natural disasters | Medium | Low | Medium term |

Response policy

Specific measures currently implemented

|

| Chronic | Water shortages and ecosystem degradation | Instability of raw material procurement and increased procurement costs due to ecosystem degradation such as depletion of water resources | Medium | Low | Long term | |||

| Transition risk | Policies and regulations | Strengthening of mining regulations | Increased procurement costs due to decline in new mine development caused by expansion of protected areas | Medium | Low | Long term | ||

| Increased procurement costs due to tighter regulations on environmental impacts such as pollution and water use during mining | Medium | Low | Long term | |||||

| Reputation | Serious impacts at procurement mines | Reputational decline from sourcing at mines that seriously impact critical natural areas or local communities due to deforestation or pollution, and reduced procurement volumes due to mine shutdowns from serious impacts | Medium | Low | Long term | |||

| Market | Demand for sustainable procurement | Increased compliance costs from demands by customers and investors for sustainability in raw material procurement | Low | Medium | Medium term | |||

JFE Engineering

Specific Categories of Findings on the Dependencies and Impacts on Nature (Evaluate)

Regarding the dependencies and impacts of our engineering business on nature, we reviewed the findings under infrastructure construction and business operation categories at our sites and procurement from our upstream supply chain at iron ore and coking coal mining sites. Our procurement and manufacturing operations depend on natural resources, particularly related to water supply, the control of water volume, and climate adjustments. Meanwhile, our infrastructure construction operations impact nature through GHG emissions and pollution. The iron ore and coking coal mining conducted upstream in our supply chain also affect nature through land use, water resource use, GHG emissions, and pollution.

Following this evaluation, we proceeded with assessments focused on infrastructure construction and upstream procurement, which have significant dependencies and impacts as well as business scale.

Assessment of Construction Sites (Locate)

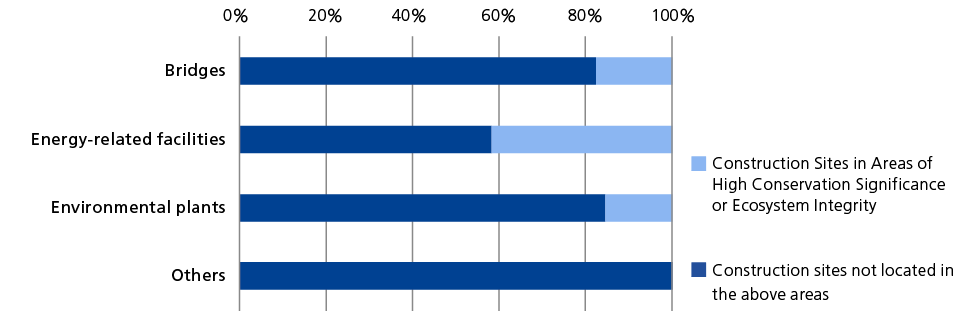

We identified the locations of domestic construction sites at a certain scale in 2024 and evaluated them based on the five criteria defined by the TNFD for priority areas. The evaluation found that some construction sites are in areas of high conservation significance or ecosystem integrity. Other criteria, such as water stress, were generally evaluated as low.

Roughly 20% of the construction sites are in areas of high conservation significance or ecosystem integrity, and when viewed by business type, many are energy-related facilities. At all construction sites, we confirmed that environmental assessments are conducted in advance regarding impacts on surrounding ecosystems and that additional measures are taken during construction to reduce ecosystem impacts.

Ratio of Construction Sites in Areas of High Conservation Significance or Ecosystem Integrity

Reviewing Nature-Related Risks and Opportunities (Assess and Prepare)

Following the above evaluation of dependencies and impacts, we organized the currently assumed nature-related risks and opportunities. The risks, some of which are recognized in our climate change scenario analysis, include physical risks that could materialize due to a water shortage or natural disaster and potentially trigger a decrease in production at our manufacturing sites or insufficient procurement from suppliers, apart from transition risks that might occur if regulations concerning protected areas and pollution are tightened.

Nature-Related Risks in Direct Operations

| Category | Item | Impact | Magnitude | Likelihood | Timeframe | Response | ||

|---|---|---|---|---|---|---|---|---|

| Direct operations | Physical risk | Acute | Intensification of extreme weather | Suspension of construction work and increased construction costs due to increased frequency and severity of natural disasters | Medium | Medium | Medium term |

|

| Chronic | Water shortages and ecosystem degradation | Suspension of construction work and increased construction costs due to ecosystem degradation such as depletion of water resources | Medium | Medium | Long term |

|

||

| Transition risk | Policies and regulations | Stricter regulations toward nature positive | Decline in new construction demand and increased compliance costs due to stricter land use regulations toward 30 by 30 | Medium | High | Medium term |

|

|

| Increased compliance costs due to stricter regulations and monitoring requirements on environmental impacts such as pollution and ecosystem disruption during construction | Medium | Medium | Long term |

|

||||

| Market / Technology | Delay in technologies addressing ecosystem considerations | Increased costs for developing and implementing technologies that contribute to nature positive and resource circulation, and loss of opportunities due to delays in response | Medium | Medium | Medium term |

|

||

| Reputation | Impact on surrounding ecosystems | Reputational decline due to adverse impacts on terrestrial and marine ecosystems caused by land use change, pollution, and disruption during construction | Medium | Medium | Medium term |

|

||

Nature-Related Opportunities in Direct Operations

| Category | Item | Impact | Magnitude | Likelihood | Timeframe | Response | ||

|---|---|---|---|---|---|---|---|---|

| Direct operations | Opportunity | Services, markets | Efficient use of construction materials | Increased demand for repair work to extend infrastructure lifespans | Large | High | Short term |

|

| Expansion of orders for environmental facilities | Increased demand and order opportunities for environmental facility construction such as for waste-to-energy plants | Medium | High | Short term |

|

|||

| Development and implementation of ecosystem-conscious technologies | Increased demand and order opportunities through construction technologies with low environmental impact | Medium | Medium | Medium term |

|

|||

| Expansion of orders through national resilience measures | Expansion of order opportunities through national resilience measures to address intensifying natural disasters | Large | High | Short term |

|

|||

Nature-Related Risks and Opportunities in Upstream and Downstream

| Category | Item | Impact | Magnitude | Likelihood | Timeframe | Response | ||

|---|---|---|---|---|---|---|---|---|

| Upstream | Physical risk | Acute | Intensification of extreme weather | Instability of raw material procurement and increased procurement costs due to increased frequency and severity of extreme weather events | Medium | Medium | Long term |

|

| Chronic | Water shortages and ecosystem degradation | Instability of raw material procurement and increased procurement costs due to ecosystem degradation such as depletion of water resources | Medium | Medium | Long term |

|

||

| Transition risk | Policies and regulations | Stricter regulations on raw materials | Increased compliance and procurement costs due to stricter regulations toward nature positive in raw material mining and requirements for sustainability certification | Medium | Medium | Long term |

|

|

| Opportunity | Resource efficiency | Efficient use of construction materials | Reduction of natural impacts and cost savings in procurement through efficient use of construction materials, leading to reduced procurement volumes | Medium | Medium | Short term |

|

|

| Transition risk | Policies and regulations | Expansion of responsibility scope for impacts on nature after construction | Increased monitoring costs and reputational decline due to construction of facilities with significant natural impacts during operation (expansion of responsibility scope) | Medium | Medium | Long term |

|

|

Measures to Address Impacts and Risks in Areas of High Conservation Significance or Ecosystem Integrity

The evaluation of construction sites in FY2024 confirmed the presence of sites in areas of high conservation significance or ecosystem integrity. Actions were taken at construction sites in these areas to avoid and mitigate impacts on ecosystems, as shown below.

Measures Implemented at Construction Sites in Areas of High Conservation Significance or Ecosystem Integrity Example

Example: Bridge repair work in Prefecture A

The site was confirmed to be adjacent to a protected area and to have high ecosystem integrity, and the following actions were taken during construction.

- In agreement with the client, the following actions were taken:

➡ For repainting, existing paint film was removed using the Eco Paint Peeling Method (EPP method)*, which employs a water-based paint stripping agent free of organic solvents.

- The work areas were sealed to prevent paint from dripping during application.

Example: Construction of an energy-related facility in Prefecture B

The site was confirmed to be adjacent to a protected area and to have high ecosystem integrity, and the following actions were taken during construction.

- In agreement with the client, the following actions were taken:

➡ A sealed conveyor system was adopted, with dust collectors installed at each dust-generating point, in order to reduce dust dispersion into the surrounding environment.

- Oil pans were installed under outdoor gear reducers so that lubricant would not leak even if the gaskets deteriorated.

- Painting was performed at factories insofar as possible, and low-VOC paints were applied in areas requiring on-site application.

Risk and Impact Management

As a holding company, JFE Holdings is responsible for the Group's comprehensive risk management under the Basic Policy for Building Internal Control Systems. Regarding initiatives for biodiversity conservation and nature positive, each operating company identifies priority areas, assesses dependencies and impacts, and evaluates risks and opportunities in line with the LEAP approach recommended by the TNFD, and the results, including priorities for action, are reflected in the JFE Group's strategy.

The JFE Group monitors risks that could affect management at the JFE Group Sustainability Council, Group Management Strategy Committee, and Management Committee. Risks and impacts related to biodiversity conservation and nature positive are also assessed in terms of timeframe, likelihood, and magnitude of impact, and the progress of efforts is reviewed. Quantitative and qualitative targets are set as KPIs for particularly important Group initiatives, and progress and performance are monitored.

For further details, please refer to:

Metrics and Targets

We monitor environmental performance and set targets, and many of these metrics are aligned with the TNFD framework. For the TNFD disclosure metrics that are not yet subject to monitoring and target setting, we will prepare for future data collection.

| Items Monitored | Target Operating Company | Metrics | Correspondence to TNFD Metrics (Global Core and Additional) |

Performance |

|---|---|---|---|---|

| Water resources | ST EN SH | Water intake | A3.0 | Environmental Data(P.269) |

| ST EN | Water discharge | C2.1 | Environmental Data(P.269) | |

| ST | Water recycling volume | A3.2 | Environmental Data(P.269) | |

| Pollution | ST EN | Hazardous substance emissions (PRTR) | C2.4 | Environmental Data(P.264) |

| ST EN | Hazardous substance emissions (COD) | C2.1 | Environmental Data(P.264) | |

| ST | Hazardous substance emissions (SOx/NOx) | C2.4 | Environmental Data(P.263) | |

| Resource circulation | ST EN | Resource input volume | ― | Environmental Data(P.266) |

| ST EN | Byproducts/waste emissions | C2.2 | Environmental Data(P.266) | |

| Use of resources | ST | Water intake and consumption from water-stressed areas | C3.0 | No intake from water-stressed areas (Japan) |

| Risk | ST EN SH | Fines due to negative impacts on nature | C7.2 | 0 yen (Japan) |

| Opportunity | ST EN | Beautification/greening expenses at production sites | C7.3 | Approx. 0.6 billion yen (Japan) |

| Items with Set Targets | Target Operating Company | Metrics | Correspondence to TNFD Metrics (Global Core and Additional) |

Performance |

|---|---|---|---|---|

| Reduction of chemical substance emissions | ST | Reduction of chemical substance emissions | C2.4 | Environmental Data(P.263) |

| Resource use | ST | Recycling of co-products | A2.1 | Environmental Data(P.266) |

| EN | Recycling rate at construction sites | A2.1 | Environmental Data(P.268) | |

| EN | Recycling rate of office recyclable waste | A2.1 | Environmental Data(P.267) | |

| SH | Expand product lineup, contributing to resource circulation | C7.4 | Initiative starting from FY2025 | |

| Effective use of water resources | ST | Efficient use of water resources | A3.0 | Environmental Data(P.269) |

Target Areas

As part of overall risk management, we identify, analyze, and evaluate water risks based on past incidents of droughts and floods in the JFE Group’s businesses, forecast data from the Meteorological Agency and results of our scenario analysis. In particular, we consider as key risks the damages to business sites and disruption of the supply chain caused by restrictions on water intake due to droughts or increasing severity of meteorological disasters. In response, we are further reinforcing measures such as using recycled water, securing alternative means, and strengthening drainage facilities.

ST Water Risk Assessment and Measures

JFE Steel identifies and evaluates water-related risks based on past incidents of damage caused by droughts and floods, forecast data from the Meteorological Agency and results of scenario analysis. We conduct a further evaluation of water risks around each manufacturing site from different perspectives by also using the World Resource Institute (WRI)’s Aqueduct, a mapping tool for evaluating overall water risks from droughts and floods in each region around the world. According to the WRI’s assessment in June 2024, water risks for all of Japan are not designated at a high level or above, but there will be risks of water shortages and flooding due to weather conditions in the future (2030s and 2040s). JFE Steel identifies steelworks under such weather risks and takes measures such as business continuity planning.

ST Raised Effluent Standards to Reduce Water Resource Pollution Risks in Iron and Steelmaking Processe

JFE Steel strives to reduce its environmental impact on waterways by thoroughly purifying water used in iron and steelmaking processes before releasing it into public waterways or sewers. The company has concluded agreements with the administrative entity in each area that set out more rigorous effluent standards, compared to those stipulated under the Water Pollution Prevention Act. It also established a strict voluntary control standard to improve water quality. For FY2023, COD*, the water quality index for wastewater, was 2.3 tonnes per day.

- *COD stands for chemical oxygen demand, an indicator for water pollution in seas, oceans, lakes, and ponds. It represents the amount of oxygen (mg/l) consumed when pollutants present in water, such as organic matter, are oxidized.

EN Proper Management in Accordance with the Water Pollution Prevention Act and Sewerage Act

Wastewater from the JFE Engineering Yokohama head office, Tsurumi works, Tsu works, and the Kasaoka Monopile Factory is released into public waterways or sewer systems. Nitric oxide, phosphorus, and COD in the wastewater are measured on a regular basis and effectively managed in accordance with the Water Pollution Prevention Act and Sewerage Act.

For more on quantitative data related to water, please refer to:

Main Initiatives for Biodiversity Protection and Nature Positive

The JFE Group endorses and participates in the Challenge Zero initiative jointly sponsored by Keidanren and the Japanese government. We are also collaborating with Yokohama City on a project that uses steel slag products to improve the marine environment while also undertaking efforts for biodiversity conservation and nature positive.

ST Complete Chromate-Free Hot-Dip Galvanized Steel Sheets

Chromate treatment using hexavalent chromium (Cr6+), an environmentally hazardous substance, has been performed employed to improve the corrosion resistance of hot-dip galvanized steel sheets, mainly used in the electrical and building materials sectors. We developed steel sheets that deliver performance equal to or greater than that of chromated steel sheets without using hexavalent chromium, and by having customers evaluate the stable performance of these products, we achieved complete chromate-free hot-dip galvanized steel sheets in 2020.

ST Contributing to Biodiversity and the Creation of an Attractive Seaside Town by Utilizing Steel Slag Products (Partnership Agreement with Yokohama City)

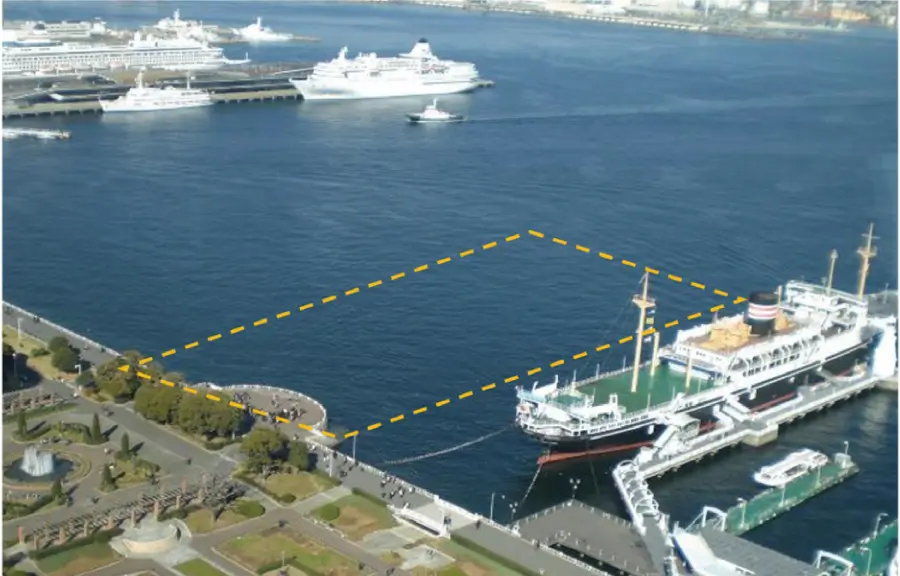

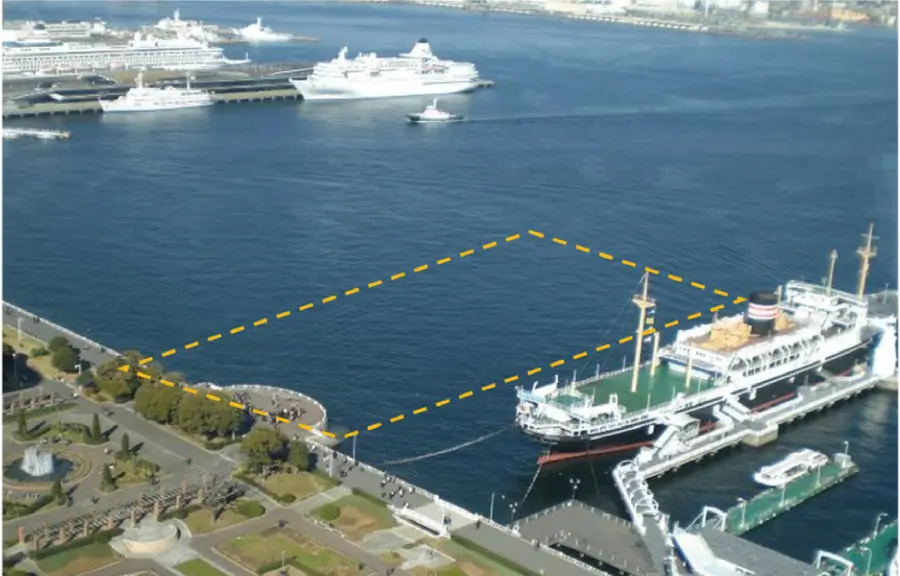

Silty sediment (sludge containing large amounts of organic matter) piles up at the ocean bed along the seaside frontage of Yamashita Park in Yokohama City, Kanagawa Prefecture, and significantly deteriorates water quality in summer. As a result, the ocean’s ability to function as a spawning ground or environment for nurturing organisms has been lost.

In a joint research project with Yokohama City, JFE Steel is restoring the intrinsic ability of the waters to purify seawater with the help of marine organisms by using carbonated steel slag products such as Marine Block™ to form shorelines as a base for the adhesion of organisms and assist in improving the marine environment. Immediately after an experiment, we observed an increase in the presence of marine organisms such as starfish and sea cucumbers around the area, and the populations continuing to grow. Moreover, we estimated that 8,400 kl of seawater (equivalent to seventeen 25-meter swimming pools) is filtered per day by filter-feeding marine creatures such as bivalves and sea squirt. We also estimated their impact on the removal of COD and the reduction of CO2 in comparison to results obtained through water purification at sewage treatment plants.

The findings from the research project were presented at many exhibits and other events, helping to raise local awareness of environmental protection. This public-private research project for improving the marine environment has earned public recognition, with Yokohama City and JFE Steel jointly receiving the FY2021 Environmental Award (Group-2) of the Japan Society of Civil Engineering*1. In September 2022, JFE Steel won the Minister of Land, Infrastructure, Transport and Tourism Award of the 5th Eco Pro Awards*2, sponsored by the Sustainable Management Promotion Organization, a general incorporated association. A signboard commemorating these awards was installed next to the sea-facing balcony in Yamashita Koen Park, displaying research findings to visitors.

- *1The Japan Society of Civil Engineering Award is a prestigious award with a history of over 90 years. The Environmental Award (Group-2) is given to an innovative project that has contributed to any combination of environmental preservation, improvement, and creation activities by developing or operating civil engineering technology or systems.

- *2The award is given to goods, services, technology, solutions, or business models with specific and outstanding eco-friendly attributes that are widely recognized by businesses, consumers, investors, and market players in the Japanese market.

- FY2021 Environmental Award of the Japan Society of Civil Engineering

- The 5th Eco Pro Award (Japanese only)

ST Agreement Concluded on the Demonstration Project for Blue Carbon Creation at the Hota Fishing Port

In March 2025, JFE Steel entered into a collaboration agreement with Chiba Prefecture, the Hota Fishery Cooperative Association in Kyonan Town, and Kyonan Town for a demonstration project to restore seaweed beds.

In Chiba Prefecture, shallow coastal areas host many rocky reefs and tidal flats with widespread seaweed and seagrass beds. Recently, however, the destruction of seaweed beds has been spreading in the Uchibo coastal area. Although there are several theories about why this is happening in Chiba coastal waters, the main causes are thought to be rising seawater temperatures and damage caused by herbivorous fish. The demonstration project is scheduled to run from April 1, 2025 to March 31, 2028. Initially, steel slag products (artificial stone) rich in iron, which is essential for seaweed growth, will be wrapped with seed strings containing seaweed seedlings and placed in the sea. To subsequently confirm the effects of seawater temperature and herbivorous fish—considered causes of the destruction of seaweed beds—seaweed growth will be monitored under varying conditions, such as species and water depth.

This demonstration project is intended to create blue carbon* and improve fishery productivity by enhancing the marine environment.

- *Blue carbon refers to CO2 sequestered by growing seaweed and other marine vegetation.

April 30, 2025, at the Hota Fishing Port

From left: Ms. Yoko Inoue, Director General, Environmental and Community Affairs Department , Chiba Prefecture

Mr. Eiji Katayama, General Manager, Slag Business Planning Division , JFE Steel Corporation

Mr. Harukazu Shiraishi, Mayor of Kyonan Town

Mr. Shigeo Murai, Representative Director and President, Hota Fishery Cooperative Association

ST Advancing Biodiversity Verification of Steel Slag Products in Collaboration with Venture Businesses

JFE Steel keeps a water tank containing the coral-covered steel slag products Frontier Rock™ and Marine Block™ at the exhibition area at the reception of the head office, offering visitors the opportunity to enjoy watching coral and tropical fish while learning about our initiative to preserve the ecosystem using steel slag products. We also intend to conduct experiments inside the tank. Innoqua Inc.* is providing technical support for the exhibition, which has been featured by several newspapers and TV programs as an example of business collaboration in the field of the environment.

- *A venture company engaged in the development of systems for managing and nurturing corals and fish by combining its aquarist know-how with IoT and AI.

Healthy coral growth on Marine Block™ (left) and Frontier Rock™ (right) inside the water tank

ST The Biotope Chita Initiative to Reproduce and Conserve the Local Ecosystem

To commemorate the 80th anniversary of its opening in 2023, the JFE Steel Chita Works established and developed Biotope Chita within the plant premises to recreate and conserve the Chita Peninsula’s ecosystem. Of the approximately 2 hectares of site area, 1 hectare had already been developed as a green belt in 2013. We are creating habitats at Biotope Chita for living organisms and conducting community-based events in collaboration with the local area.

ST The Chita Works Certified as an Aichi Biodiversity Company

In November 2022, our Chita Works was recognized as a certified enterprise under the Aichi Biodiversity Company Certification Program in its first term launched by Aichi Prefecture based on the Aichi Biodiversity Strategy 2030. The program is intended to encourage more businesses in the prefecture to play a pivotal role in preserving local biodiversity by certifying those that have implemented outstanding initiatives to do so.

We have used Biotope Chita at the Chita Works since FY2022 to create green spaces that attract the chestnut tiger butterfly, a species that migrates more than 2,000 kilometers across Japan, and we have partnered with municipalities in the Chita Peninsula of Aichi Prefecture to exchange information on butterfly arrivals. We are also engaged in conservation activities for native species such as the Japanese rice fish (Oryzias latipes) and Japanese honeybee (Apis cerana japonica). We have further strengthened our initiatives since FY2024 by undertaking ex-situ conservation of wetland plants.

ST Biotope Chita Certified as a Nature Symbiosis Site

Biotope Chita, the biodiversity conservation base of the Chita Works, was certified as a Nature Symbiosis Site by the Ministry of the Environment in March 2025. The certification was obtained as a result of Chita Works joining in 2024 the previously certified Inochi wo Tsunagu Projec t*2, which operates in the Greenbelt of Chita peninsula *1.

A Nature Symbiosis Site is an area that promotes biodiversity conservation through private initiatives and other efforts, certified by the Government of Japan under a system led by the Ministry of the Environment. It is one of the initiatives for achieving the international 30 by 30 target to effectively conserve more than 30% of land and sea as healthy ecosystems by 2030. This certified area is a portion of Biotope Chita (0.66 ha). Certification was granted following monitoring surveys that confirmed the conservation of biodiversity, having identified 86 plant and 16 bird species. Going forward, JFE Steel Chita Works will also obtain independent certification and further strengthen its initiatives.

- *1The Greenbelt of Chita peninsula (76.33 ha) is a forest belt in the coastal industrial area of the Chita Peninsula. In 2011, efforts began under the Inochi wo Tsunagu Project, a wide-area collaboration focused on biodiversity. Activities include improving the quality of green spaces, creating pathways for species to move freely between green spaces, and creating habitats for living organisms.

- *2The Inochi wo Tsunagu Project was launched in 2011 following COP10 in Nagoya in 2010. The project views green spaces managed by companies along the coastal area of the Chita Peninsula as one large green belt and seeks to promote integrated conservation and management beyond corporate boundaries, including periodic information exchange meetings, collaborative activities to promote biodiversity conservation, and joint awareness-raising events.

ST Initiatives for Blue Carbon Using Steel Slag Products and Acquisition of J Blue Credit™

In recent years, research on blue carbon (carbon absorbed and stored by living organisms in the ocean) has been advancing. We are also creating seaweed beds using steel slag products and measuring the total carbon absorption of these beds.

JFE Steel has been promoting the research while creating a seaweed bed using steel slag products and measuring the amount of carbon captured by the entire bed. The company has been collaborating with Koujiro Fisheries Cooperative (Iwakuni City, Yamaguchi) and the National Institute of Technology, Ube College (Ube City, Yamaguchi) on a project to create a seaweed bed and ecosystem using recycled materials at areas around Shinto, Iwakuni City, since FY2012. The initiative involves creating a seaweed bed with rich biodiversity using Marine Stone™, a grain-size-adjusted steel slag, and other steel slag products, and measuring CO2 absorption of the created beds. The cumulative amount of CO2 absorbed and stored from 2018 to 2023, which totaled 81.4 tonnes, received J Blue Credit™ certification by the Japan Blue Economy Association. This was the first certification ever given to a three-party joint project by the Fisheries Cooperative, academia, and private business. The seaweed bed created through the project had the co-benefits*1 of offering a gathering place for diverse fish. Additionally, the sea area is used for education and research.

This initiative was highly regarded, and its members and JFE Steel received the Ministry of Agriculture, Forestry and Fisheries Prize for the 32nd Global Environment Award*2 in 2024.

- *1Climate co-benefits are the positive impacts beyond greenhouse gas reduction that result from climate action policies and projects.

- *2The Global Environment Award recognizes environmental preservation and related efforts that will help establish a circular society for a “harmonic coexistence between industrial development and the environment of the Earth.”

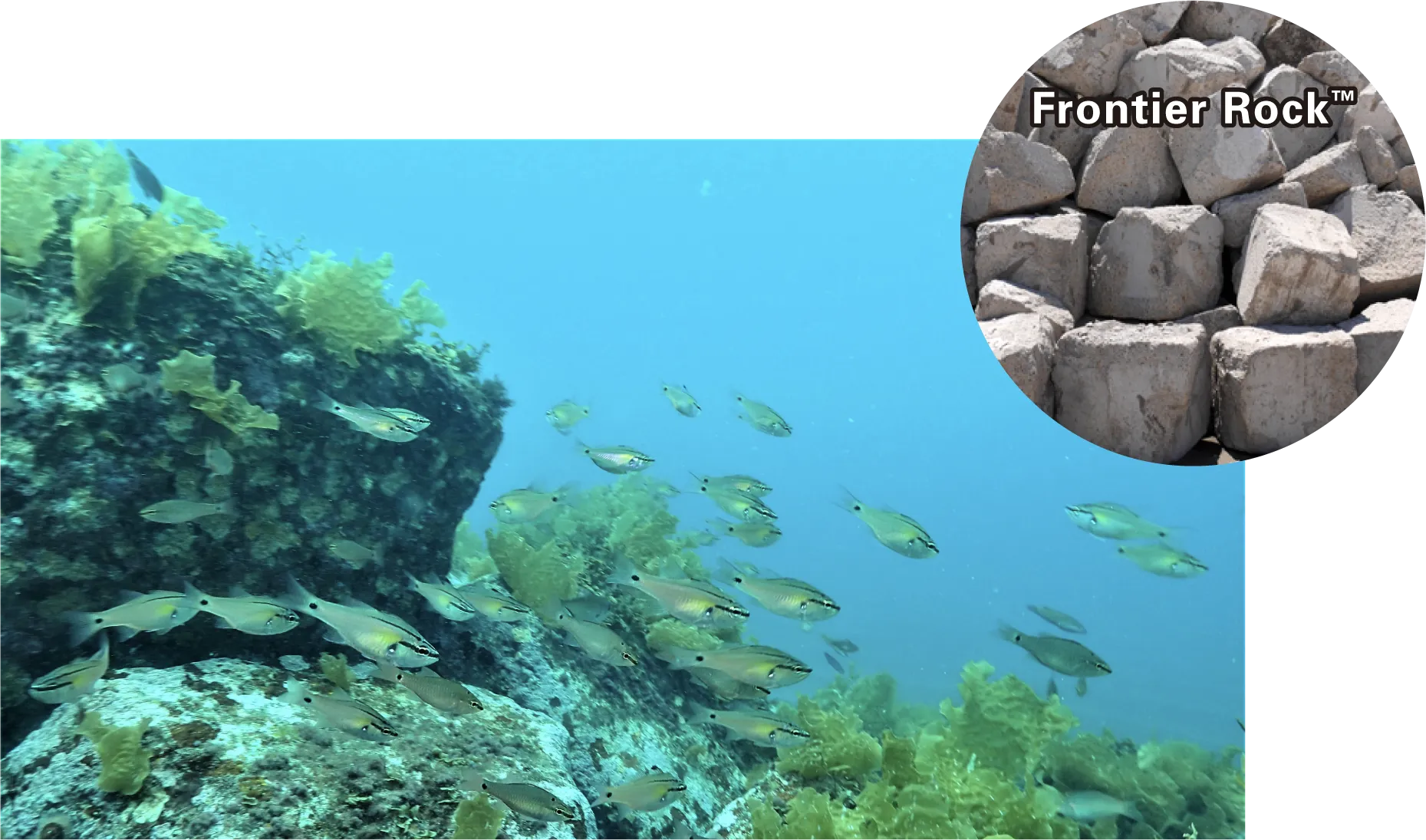

ST Restoring Marine Ecosystems Using Steel Slag Products

Marine Stone™ is a grain-size-adjusted steel slag that controls the generation of hydrogen sulfide from the silty sediment in enclosed coastal seas and improves the environment in which organisms can live. Its effectiveness in improving marine environments is widely recognized, and the joint project with Hiroshima University has received external commendations.

Frontier Rock™ is another steel slag product that consists of artificial stones made from a steel slag hydrated matrix and provides an excellent base for seaweed beds and fishing reefs. A submerged bank built on the seabed off the coast of Minami-Izu Town, Shizuoka Prefecture, has become a gathering place for large perennial seaweeds as well as useful fishery resources such as lobsters and a wide variety of fish.

ST Calcia Improvement Material

Calcia improvement material* is a slag product that uses converter-type steelmaking slag as raw material and is manufactured by controlling composition and adjusting particle size. Calcia-improved soil can also be used for creating shallow waters, tidal flats, and embankment material and as backfill material for deep excavation pits left by marine sand extraction. It contributes to improving the marine environment. To date, it has been used as the main embankment material for creating a shallow area (incidental facilities at the sediment disposal site, Tokuyama-Kudamatsu Port).

EN Initiatives in the Engineering Business for the Preservation of the Natural Environment and Biodiversity

In engineering projects, at waterfronts, in mountainous areas, or in large-scale construction efforts, customers and related organizations often conduct preliminary surveys in advance, depending on the importance of conserving the surrounding environment, and various environmental protection conditions may be imposed on the work, including measures for protecting living organisms.

JFE Engineering respects the proposed conditions and thoughtfully considers biodiversity conservation by keeping the impact of construction works at a minimum. For example, the company may propose a construction method that minimizes the impact of noise or drainage pollution. For its steelworks, the status of biodiversity on its premises and in surrounding areas are checked, and necessary measures are taken to ensure preservation.

Our construction projects adopt methods that comply with customer requirements. For example, reference is made below to Biodiversity Conservation in the Reconstruction of the Tedori River Bridge and Contribution to Japan’s First Communication Optical Fiber Cable Installation across Tokyo Bay Using the Curved Pipe Jacking Method.

We also engage in community activities that contribute to the conservation of local natural environments and biodiversity.

EN JFE Engineering: Biotope for Children’s Learning Experience

JFE Engineering has conducted some renovation work at the JFE Dragonfly Path in the Tsurumi Works, and since 2009 it has been inviting children in the community to learn about the ecosystem at a biotope, Dragonfly Pond, located along this path.

The JFE Dragonfly Path Fan Club, a group mainly composed of neighborhood residents, has organized a research event that involved capturing dragonflies in order to learn about their ecology and the local environment.

We are also a founding member of the How Far Do Dragonflies Fly Forum , which aims to improve the quality of green spaces in the Keihin coastal area and contribute to biodiversity. The forum brings together companies, residents, governments, and experts and conducts research activities such as capture, tagging, and release of dragonflies that fly in 15 green spaces and biotopes scattered throughout the Keihin coastal area and inland areas to track their movements. The JFE Dragonfly Path also serves as a research site.

These activities were certified in 2024 by the Ministry of the Environment as a Nature Symbiosis Site under the designation “Yokohama/Keihin Forest.”

EN Participation in Kanagawa Prefecture’s Reforestation Partner Program

In March 2023, the JFE Engineering Group’s J&T Recycling Corporation expressed its support for the Kanagawa Reforestation 50 Year Plan and signed a memorandum of understanding with Kanagawa Prefecture on the Reforestation Partner Program*, an initiative launched by the prefecture.

The company’s intent is to use the program as part of its environmental protection and harmony activities while supporting the prefecture’s vision. Under the partnership, the company’s employees volunteer to help thin trees and take part in other efforts for conserving forests, a valuable source of water for future generations.

The Reforestation Partner Program grants naming rights to participants for parts of the prefecture-owned forests, one of which is now called the J&T Kankyo Miracle Forest (with the word “miracle” expressed in kanji, meaning the “future is coming”). J&T Recycling Corporation is constantly enhancing its ESG initiatives to improve the environment.

- *For details about the Reforestation Partner Program, please refer to:

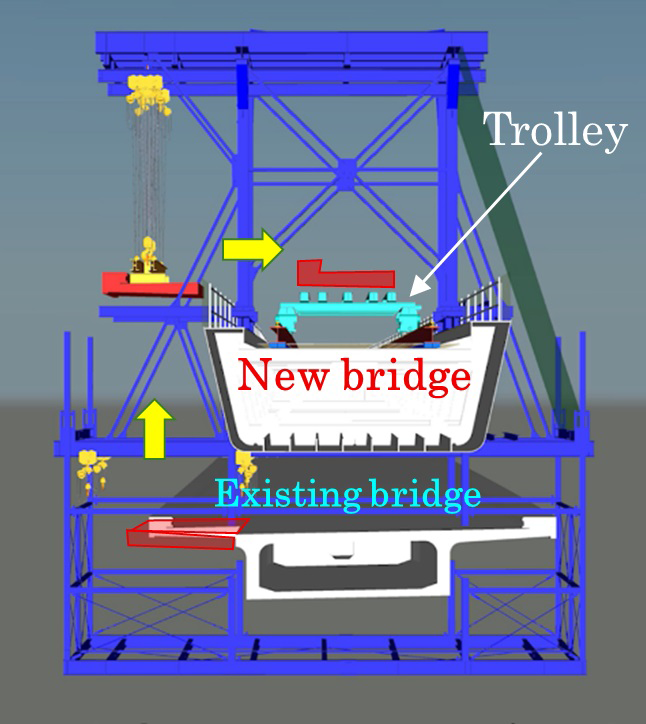

EN Biodiversity Preservation in the Reconstruction of the Tedori River Bridge

The reconstruction of the Tedori River Bridge* is described under the heading “Toward Realization of Longer Service Life Bridges” in the Initiatives to Transition to a Circular Economy section of this Sustainability Report 2025. The project is characterized not only by the use of stainless clad steel but also by the adoption of a special reconstruction method necessitated by local site constraints. The bridge is located at the mouth of the Tedori River, and the sandy beach beneath the girders is inhabited by the Iso-komori spider (Lycosa ishikariana) and the Little Tern, both listed as endangered species (Category II). We therefore developed a reconstruction method that avoids bringing heavy machinery onto the sandy beach to protect these rare species.

The construction method begins by assembling the new bridge on top of the existing one before its removal and then installing a removal frame on the new bridge. Using this frame, the girders are cut in mid-air, lifted onto the new girders, placed on transport vehicles, and carried out of the bridge area. This reconstruction method was developed by JFE Engineering, combining multiple techniques derived from similar experiences in urban expressway reconstruction and widening projects and applied to the site after full-scale construction trials.

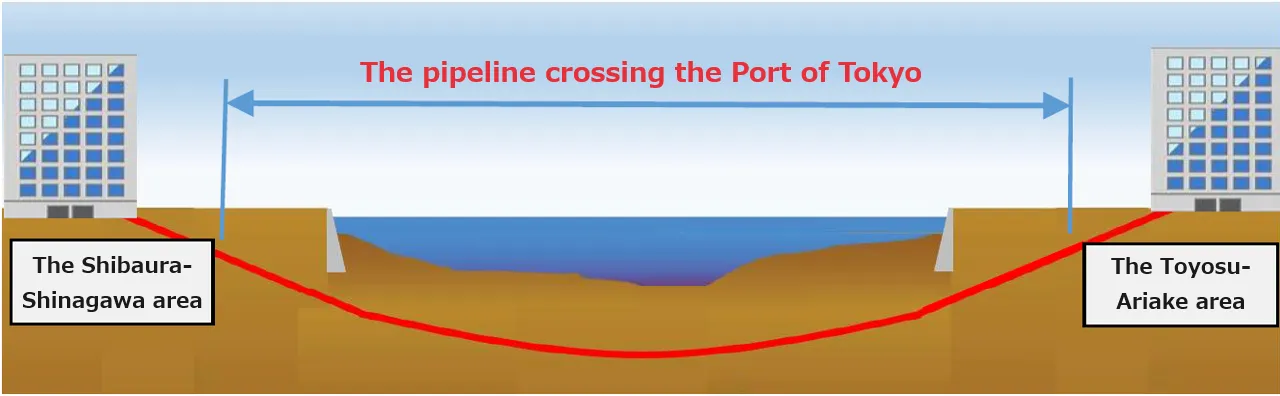

EN Contributing the Company’s Horizontal Directional Drilling Method to Japan’s First Installation of Telecommunication Optical Fiber Cables across Tokyo Bay

JFE Engineering has completed the construction of a transmission channel across Tokyo Bay as a project ordered from Nippon COMSYS Corporation. The ongoing advance of information and telecommunication technologies have made telecommunication networks indispensable in daily life, and the growing volume of telecommunication traffic requires an increasing number of optical communications facilities.

Construction involved laying a pipeline for installing telecommunication optical fiber cables between Tokyo’s Shibaura and Shinagawa areas, where many tech companies are located, and between the city’s Toyosu and Ariake areas, thereby establishing a network with the shortest route. The challenging work required laying the pipeline deep undersea to prevent damaging seawalls and other protection structures around Tokyo Bay as well as handling nearly 2,000 meters of pipeline, one of the longest in Japan. The construction was completed successfully without accident within just two months, thanks to the use of the JFE-RAPID™ method, a pipeline technology developed by JFE Engineering to facilitate quick, low-cost construction.

The JFE-RAPID™ method makes it possible to bring down construction cost and shorten the work period by drilling at the sea bottom and moving the pipeline forward through a circular boring method instead of installing vertical shafts. This is an effective method for installing telecommunication cable and a promising technique for laying power cable pipelines for offshore wind-power stations.

The pipeline (concept)

Initiatives for Realizing Nature Positive in the Keihin Waterfront Area

The shared urban space under OHGISHIMA2050 is envisioned as a green, future-oriented venue for demonstration and interaction of advanced technologies supporting DX and GX. In collaboration with Kawasaki City, we are exploring the creation of a nature-positive urban space that fosters biodiversity.

As part of land use initiatives in the Keihin area, we are planning to promote the promotion of CCUS projects by leveraging the expertise and know-how cultivated in advanced CCS projects, contributing to ecosystem conservation through businesses that support carbon neutrality. Land use conversion in the Keihin area involves dismantling large idle facilities such as steelworks and coke plants. Through the recycling of scrap, concrete, and other materials, we are working to reduce environmental impact. At Ogishima, we have continued operations as a steelworks rich in greenery, conducting extensive greening initiatives to create a people- and environment-friendly site. In land use conversion as well, we will aim to realize an urban environment that takes biodiversity and resource circulation into consideration.