Environmental Management

Basic Policy

JFE Group companies are developing innovative technologies and international cooperation for the protection of the global environment by operating in harmony with the global environment, as well as protecting it, in accordance with the Group’s environmental philosophy and policy.

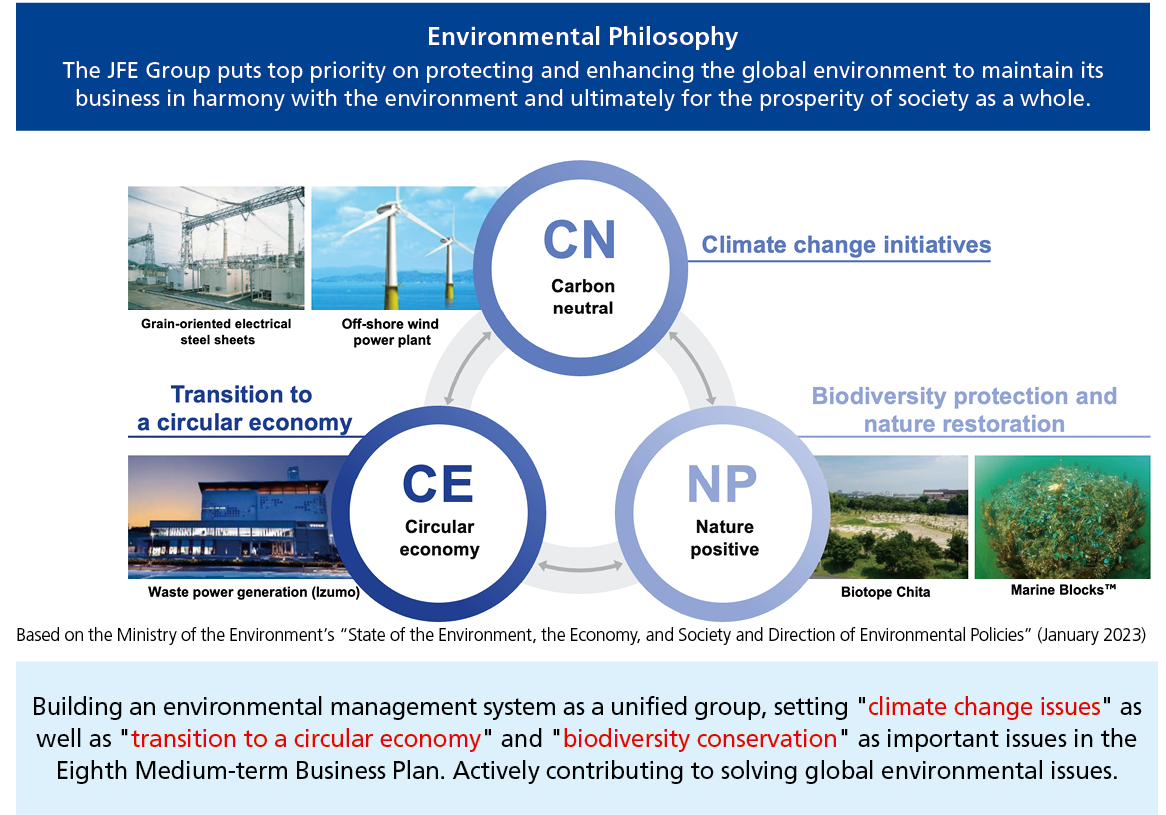

Environmental Philosophy

The JFE Group puts top priority on protecting and enhancing the global environment to maintain its business in harmony with the environment and ultimately for the prosperity of society as a whole.

Environmental Strategies

- Reduce the environmental impact of all businesses

- Contribute through technologies and products

- Contribute through businesses for resource conservation and energy efficiency

- Communicate with society

- Facilitate international cooperation

Management Structure

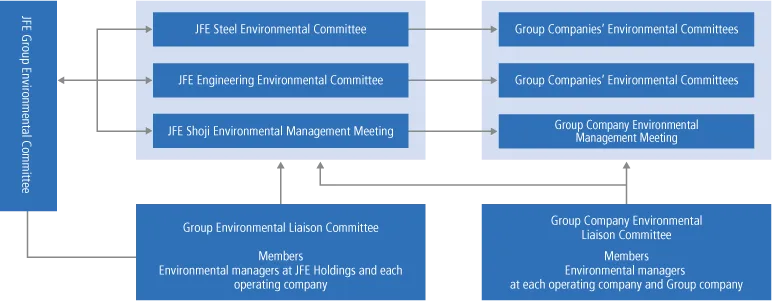

Framework for Environmental Management

The JFE Group Environmental Committee, chaired by the president of JFE Holdings and operating under the JFE Group Sustainability Council, sets goals for environmental protection, monitors the progress of these initiatives and works to improve the Group’s overall environmental performance. Key issues for corporate management such as climate change are deliberated at the Group Management Strategy Committee as well and reported to the Board of Directors. The board oversees environmental challenges by discussing the reported material. Additionally, specialized committees set up by JFE Group operating companies and affiliates implement specific activities.

We will continue to place top priority on addressing climate change from the perspective of business continuity and are striving to achieve carbon neutrality by 2050. In addition to addressing climate change, our Eighth Medium-term Business Plan designates the transition to a circular economy as well as biodiversity conservaion and nature positive as key issues, and we will actively contribute to resolving global environmental concerns.

For further details, please refer to:

- System for Promoting Sustainability

- Eighth Medium-term Business Plan

- JFE Group Environmental Vision for 2050

Environmental Management System

Initiatives

Environmental Management System

Acquiring ISO 14001 certification is a key part of every JFE Group company’s environmental program. In accordance with the requirements of ISO 14001, each registered organization reviews its environmental policy, legal requirements, and progress toward achieving last year’s targets and activities, and then formulates and communicates environmental targets and action plans for the coming year. In addition to periodic reporting and reviews within the organization, audits are conducted as necessary to confirm results. Annual results are evaluated through management reviews, and deliberation on future initiatives incorporates these findings into next year’s plans.

All global production sites of JFE Steel and JFE Engineering and major offices of JFE Shoji have been certified, encompassing 66% of 43,243 employees at 82 companies covered in this report and 52% of all sites. In FY2024, there were no major violations of environmental laws or regulations by Group companies (air, water, soil, etc.) that resulted in a fine or other penalty.

For quantitative data related to ISO 14001 for each business, please refer to:

ST Environmental Committee and Environment Management Committees Provide Appropriate Management Supervision

JFE Steel maintains Environment Management Departments at its head office and in each business office, as well as an Environmental Committee, chaired by its president, and Environment Management Committees in each local office. In addition, the Management Committee deliberates and sets materialities and KPIs, including those related to the environment, and evaluates performance. In FY2024, we achieved our target of reducing CO2 emissions by more than 18% compared to FY2013, and by stimulating demand for green steel, we expanded the adoption of JGreeX™ and received orders across all sectors, thereby achieving our environmental KPIs. Starting in FY2025, we will set new materialities and KPIs related to the circular economy, biodiversity conservaion, and nature positive activities, and follow through to take action.

- Environmental Management System (Environmental Strategies) (Japanese only)

- FY2024 KPI Results and FY2025 KPIs

EN Environmental Committee Oversees Environmental Management

JFE Engineering maintains an Environment Management Department at each of its major locations, including production sites and branch offices as well as all divisions in charge of products. The Environmental Committee, chaired by the president, oversees environmental management for the entire company. Under its Environmental Management System, JFE Engineering works to minimize environmental impact at production sites, branch offices and construction sites and contribute to environmental protection through all products and services. The major strategies for FY2025 are (1) promote environmental contribution through products for mitigating global warming and climate change, (2) promote environmental protection, effective energy conservation, and resource recycling in business activities, and (3) ensure thorough compliance with environmental laws and regulations. We are reflecting these strategies into the related operations. These strategies are incorporated into related operations and are addressed.

SH Expand ISO 14001 Certification Acquisition Coverage

JFE Shoji obtained ISO 14001 certification for its head office, Osaka branch, and Nagoya branch in 2000 and later expanded the scope of certification to all domestic offices. JFE Shoji also applies the same environmental management system to domestic Group companies, promoting the same environment management activities and striving for the same certification. Overseas coil centers are also planning to acquire ISO 14001 certification.

Environmental Audit

In addition to the regular internal and external audits at ISO 14001-certified sites, the audit and environment departments at each operating company’s head office conduct independent environmental audits at their production sites.

ST Conduct Detailed Audits

Once a year, JFE Steel’s Audit Department and the Environment, Disaster Prevention and Recycling Department conduct an environmental audit at each operational site. JFE Steel categorizes Group companies based on the result of risk assessment considering owned equipment and conducts detailed audits every one to five years using checklists.

In FY2024, we conducted audits of 17 Group company sites.

EN Conduct Audits to Confirm Compliance with Environmental Laws and Regulations

JFE Engineering places top priority on complying with environmental laws and regulations.

For JFE Engineering’s production sites in Japan (Tsurumi, Tsu, and Kasaoka), the Safety and Environment Department conducts environmental law compliance audits as well as internal audits of the environmental management system. In addition, the department annually audits about 50 locations selected from construction sites in Japan and Group companies to confirm compliance with environmental laws and regulations. Furthermore, at JFE Engineering, environmental inspections are conducted at approximately 70 locations annually (including about 30 construction sites and plant operation sites) to evaluate the effectiveness of initiatives for improving environmental performance and take remedial action. Annual environmental inspections to confirm compliance with environmental laws are conducted by the departments responsible for all construction, and self-checks of legal compliance are carried out every year at production sites (Tsurumi, Tsu, and Kasaoka).

SH Conduct Internal Audits and Environmental Audits

The JFE Shoji Group conducts internal environmental audits once a year for ISO 14001-certified Group companies, and environmental audits are conducted once every three years for non-certified group companies to confirm on-site compliance with laws and regulations. In FY2024, we conducted internal audits of all 54 ISO-certified organizations and an environmental audit of one non-certified company.

For quantitative data related to environmental audits, please refer to:

Environmental Education

The JFE Group actively provides education to foster a corporate culture of environmental protection. Education at operating companies includes training for new recruits and newly promoted employees as well as specific environmental-protection training by position and job.

For Groupwide environmental training, we hold an annual Review Session on Environment-Related Laws and Regulations, to which lawyers specialized in environment-related laws and regulations are invited to give lectures on the latest information related to the enactment and revision of these laws, as well as associated violations and court decisions. Employees from wide-ranging departments, including the environment, disaster prevention, legal affairs, general affairs, and manufacturing departments of the operating companies and their group companies, who are involved in environment-related activities, attend these annual sessions as the basis for planning their activities, such as educating employees and raising awareness about the Group’s policies and initiatives.

ST Promote Pollution Control Managers Acquire Qualifications

JFE Steel encourages employees to obtain qualifications as pollution-control managers. A training program for environmental managers at Group companies was launched in FY2011. In addition, JFE Steel provides employees with training to ensure compliance with environmental laws, disseminates information about regulatory revisions at its Environmental Liaison Committee meetings for Group companies, and organizes brush-up training in waste management skills for on-site personnel.

EN Provide General Environmental Education

JFE Engineering educates all employees about environmental issues to increase their understanding of the company’s policies and initiatives. To ensure proper environmental management at production and construction sites, training is often tailored to specific employee operations, helping to enhance their capabilities. In FY2024, we revised the distributed video materials for environmental law education to make them easier to use and encouraged greater participation.

SH Provide General Environmental Training and Specialized Training for Internal Audit Staff

JFE Shoji provides all employees with general environmental training in compliance with ISO 14001 and specialized training for internal audit staff. All employees within the scope of certification receive a pocket-size ISO Employee Card to carry with them so they can check the details of ISO 14001 activities at any time. In addition, each company performs a self-check using its own extensive checklist to ensure understanding and rigorous compliance with environmental laws. Also, JFE Shoji provides environmental training to new executives and information about revised laws and regulations to environmental management personnel.

Environmental Impact Reduction Initiatives

The JFE Group regards co-existence and mutual prosperity with local communities, the global environment, and society at large as a critical managerial challenge in terms of business continuity. It strives to control air and water pollutant emissions and aggressively invests in environmental protection. Related internal controls and education are steadily being strengthened as well. Also, the transfer and widespread application of proprietary technologies, mainly in developing countries, contribute to pollution prevention on a global scale.

For quantitative data related to reducing environmental impact, please refer to:

Controlling Air Emissions

ST Initiatives to Further Reduce SOx and NOx Emissions

JFE Steel is installing low-nitrogen oxides (NOx) burners in reheat furnaces, switching to low-sulfur fuels and deploying desulfurization and denitration devices in sintering plants, all major sources of sulfur oxides (SOx) and NOx emissions. It has concluded agreements with local administrations that stipulate conditions that are stricter than the total volume restrictions required by the Air Pollution Control Law. The company is continuing to further control emissions at a level that is less than the amount set forth in the agreement. In addition, the company suppresses dust dispersion through measures that include enhancing on-site cleaning, installing sprinklers and windbreak fences in raw material yards, and improving the performance of dust collectors.

EN Appropriate Management in Place to Restrict SOx and NOx Emissions

To ensure compliance with the Air Pollution Control Law and relevant local regulations, JFE Engineering properly manages facilities that emit soot and smoke at its Yokohama head office, Tsurumi works, and Tsu works, so NOx and SOx emissions from those facilities are maintained at a level sufficiently lower than the total annual volume restriction (NOx: 18,000 Nm3, SOx: 100 Nm3).

Environmental protection efforts are underway at construction sites and plant operation sites through the strict use of construction machinery and on-site vehicles in compliance with the Automotive NOx and PM Law and the Act on Regulation, Etc. of Emissions From Non-road Special Motor Vehicles (Off-Road Vehicle Law).

In addition, we strive to prevent leakage at the aforementioned sites and temporary locations such as construction sites by inspecting equipment using fluorocarbons and ensuring proper disposal in accordance with the Fluorocarbons Emission Control Act.

Management of Chemical Substances and Emission Control

ST Initiatives to Reduce VOC Emissions

JFE Steel lowers its environmental impact by voluntarily reducing the chemical substances it releases. Release and transfer amounts of substances subject to Japan’s Law concerning Pollutant Release and Transfer Register (PRTR Law) are reported in accordance with the law.

The Japan Iron and Steel Federation formulated a voluntary action plan to reduce VOC emissions by 30% from FY2000 levels by FY2010. As part of this action plan, JFE Steel set a target for reducing emissions to 1,078 tonnes or less. As a result of our initiatives, we achieved a significant reduction that exceeded the 30% reduction target in FY2010 and have been consistently cutting VOC emissions, by more than 50%. Going forward, we will continue to maintain the emissions below 1,078 tonnes and take the necessary steps to prevent any increase.

Emissions of benzene and dichloromethane are kept at low levels. We will continue to set targets for the two substances and maintain low emissions levels.

EN Management of Chemical Substances in Accordance with the PRTR Law

Major chemical substances subject to the PRTR Law for the JFE Engineering works in Tsurumi, Tsu, and Kasaoka include organic solvents such as xylene used for painting products, manganese and its compounds generated during welding. We report the release and transfer amounts of these substances in accordance with the law.

PCB Waste Management at JFE

Polychlorinated biphenyl (PCB) waste is properly stored and managed at the JFE Group’s facilities. High-concentration PCB waste has been treated under the guidelines set by the Japan Environmental Storage & Safety Corporation (JESCO), and the treatment is almost completed. Low-concentration PCB waste is being treated under contracts with certified detoxification contractors. The Yokohama Eco Clean Plant of J&T Recycling Corporation treats insulating oil contaminated with slight amounts of PCB, helping to reduce pollutants both in and outside the JFE Group.

Environmental Accounting

Basic Policy

The JFE Group is saving energy and reducing its environmental impacts by making its production facilities increasingly efficient and introducing more environmentally friendly equipment. Any equipment or facilities related to energy conservation and environmental protection are categorized as environmental investment, while all activities related to environmental protection and impact reduction are categorized as environmental expenses.

Through these environmental investments and expenses, we are working to lower unit-based CO2 emissions to prevent global warming and to reduce final-disposal waste by maintaining a high recycling rate to effectively use natural resources. We are also striving to reduce emissions of pollutants into the water and air, which contributes to environmental protection and ensures thorough compliance with statutory regulations concerning exhaust gas emissions and discharged water.

For quantitative data related to environmental accounting, please refer to: