Policy Engagement

Basic Approach to Policy Engagement on Climate Change Issues

The JFE Group has identified climate change as a top priority and formulated both the JFE Group Environmental Vision for 2050 to achieve carbon neutrality by 2050 and its long-term JFE Vision 2035. To realize these aspirations, JFE Steel is focusing on the early implementation of ultra-innovative technologies and expanding the supply of green steel. However, long-term technology development, investment in the construction of large-scale decarbonization infrastructure, and ensuring investment predictability by creating demand for green steel and other Green Transformation (GX) products require bold and powerful industrial policies from the government as well as collaboration with society, including stakeholders. We therefore actively recommend policies through the Company and related organizations and disclose the results of our lobbying activities.

In particular, JFE Steel not only seeks to enhance corporate value but also contributes to the realization of carbon neutrality, which in turn will contribute to sustainable development worldwide. Accordingly, the Company makes recommendations regarding Japan’s climate change policies as well as GX and energy policies, taking into account the Paris Agreement, and proactively engages in and contributes to activities through industry associations.

In addition, each Group company participating in industry associations and initiatives regularly informs the Group’s thinking, direction, stance, and influence, and reviews its proposals and participation. Key decisions are discussed at the Group Management Strategy Committee and further deliberated and decided at the Board of Directors.

Stance on Major Policies

The JFE Group views government GX policies as a key framework for realizing a sustainable society. We support the GX2040 Vision and are developing our business activities and environmental strategies in alignment with the directions of these policies. Our stance on GX policies and specific initiatives are described below.

GX Policies

The government’s GX2040 Vision presents long-term directions and policy guidelines to enhance investment predictability for GX as a national strategy toward achieving both a decarbonized society and industrial development.

In the steel business, bold and powerful government support is required for long-term technology development, increased operating costs associated with process transitions, and infrastructure development to meet higher electricity demand. Also essential are support systems for building hydrogen and ammonia supply chains as decarbonized fuel infrastructure, promoting CCUS, and creating markets that properly value GX products, such as green steel. We will strive Companywide and through industry associations to recommend policies and promote public understanding to ensure the directions set forth in this vision are advanced as concrete policies.

Energy Policy

The principle of “S+3E” in the government’s 7th Strategic Energy Plan stands for safety as a major premise, energy security as the highest priority, and improvement of economic efficiency and compatibility with the environment, in concert with policies calling for the transition of renewable energy into a mainstay power source and for maximizing the use of nuclear power.

The reduction of byproduct gas previously used as an energy source will significantly boost electricity demand in the steel business’s decarbonization efforts, particularly in process transitions at integrated blast furnace steelworks. Therefore, the stable, medium- to long-term supply of decarbonized power, realization of internationally competitive industrial electricity prices, and the development and rebuilding of transmission infrastructure will be essential. The construction of hydrogen and ammonia supply chains as decarbonized fuel infrastructure is also necessary. We will work Companywide and through industry associations to recommend policies and promote public understanding to ensure that concrete policies are advanced in line with this plan.

Carbon Pricing

The government’s growth-oriented carbon pricing scheme calls for the full-scale launch of the GX-ETS emissions trading system (GX-ETS) in FY2026 and the introduction of a fossil fuel surcharge system in FY2028. Under this policy package, the government is committed to large-scale support for technology development and capital investment for decarbonization while gradually introducing carbon pricing. We support this policy that encourages taking on the challenge of developing innovative technologies for carbon neutrality.

We will make the necessary policy recommendations Companywide and through industry associations based on this scheme to introduce effective systems for developing and implementing innovative technologies in the Japanese steel industry while maintaining and enhancing international competitiveness. In addition, we believe that ensuring investment predictability for GX requires that both the introduction of carbon pricing as well as policies to create markets for GX products proceed in tandem.

Creation of GX Product Markets

Products arising from the transition into decarbonization processes (defining GX products as those producing reduced GHG emissions over their life cycle through decarbonization investments) typically carry higher costs, so it is unlikely that demand will spontaneously emerge through market forces alone. Coordinated action will be needed to create a market environment that recognizes GX value. Specific measures include public-private initiatives to stimulate demand and mechanisms that ensure that GX value is recognized and incentivized throughout the entire supply chain. These steps are essential to support widespread adoption of GX products.

For the steel industry in particular, from the perspective of ensuring the necessary investment predictability for decarbonization, the actual emission reductions from the Company’s own efforts must be understood and recognized as GX value, which in turn will depend upon promoting understanding and creating transparent and reliable communication guidelines. JFE Steel is recommending policies and raising public awareness to ensure the advance of concrete initiatives by both the public and private sectors to expand GX product markets while also actively participating in rule and standard-setting efforts in domestic and international industry associations and global initiatives.

Initiatives to Materialize Demand Creation Measures

JFE Steel is collaborating through its participation in industry associations to take concrete action for boosting green steel demand by recommending policies and engaging in activities to raise awareness targeting the government and relevant organizations.

In March 2024, the Ministry of Economy, Trade and Industry (METI) published the Interim Summary of the Study Group on GX Product Markets for Demand Creation Contributing to Industrial Competitiveness Enhancement and Emission Reduction. This report suggests “Reduced Emissions of Product” as a new GX value and emphasizes the importance of monetizing actual emission reductions resulting from a company’s efforts.

At the Study Group on Green Steel for Green Transformation hosted by METI in November 2024, we made recommendations on the need to create demand for green steel as well as the required policy support. The summary report of this study group confirmed a common understanding of the need for early action to create demand and clarified the definition of “Green Steel for GX.” It also established a policy direction in which the government places priority on policies such as preferential procurement and purchase support for steel products that reflect the value of emission reductions in the steelmaking process. Specifically, beginning in FY2025, these policies will be implemented by reflecting the criteria for products subject to preferential procurement under the Act on Promoting Green Procurement and by reflecting additional criteria for subsidies to promote the introduction of clean energy vehicles.

In addition, as a result of activities in the Rules Working Group of the GX League in which JFE Steel participated, a framework for the GX Acceleration Declaration was launched, whereby companies voluntarily declare their procurement of GX products and disclose and evaluate the content. Based on this initiative, JFE Steel has declared its procurement of GX products and is actively promoting the creation of private sector demand as well.

- METI: Interim Summary of the Study Group on GX Product Markets for Demand Creation Contributing to Industrial Competitiveness Enhancement and Emission Reduction (Japanese only)

- METI: Consolidated Summary of the Study Group on Green Steel for Green Transformation

GX Acceleration Declaration

- METI: GX Acceleration Declaration Framework Newly Launched as Effort to Encourage Companies Proactively Engaging in Creation of a Market for GX

- JFE Steel GX Acceleration Declaration (Japanese only)

Initiatives for Setting Rules and Standards in Japan and Overseas

The Japan Iron and Steel Federation (JISF) has taken the lead globally by formulating and publishing guidelines for green steel that reflect the value of reduced emissions. At the World Steel Association, guidelines on steel products using the Chain of Custody* approaches were also formulated and published based on the JISF guidelines. JFE Steel is actively participating in and promoting rulemaking in these industry organizations.

In addition, discussions on standardization are also progressing at international organizations such as the International Organization for Standardization (ISO), the GHG Protoco l, and the Science Based Targets initiative , and JFE Steel is involved either on its own behalf or through industry associations.

- *A framework for tracking and recording how products and raw materials move and are managed through the supply chain.

- Japan Iron and Steel Federation: Guidelines on Green Steel (Japanese only)

- World Steel Association: GHG chain of custody approaches in the steel industry

Lobbying Activities and Outcomes

The JFE Group is contributing to the realization of a carbon-neutral society by advancing the development of ultra-innovative technologies and the transformation of the steelmaking process. At the same time, it is actively engaging in policy formation to enhance the sustainability of society as a whole. In particular, we hope to accelerate decarbonization and industrial competitiveness through constructive lobbying efforts that reflect the realities of the industry regarding national strategies such as GX and energy policies and by ensuring their inclusion in institutional design.

Specific outcomes of these activities include the incorporation of the Group’s recommendations into policies such as the GX2040 Vision and the 7th Strategic Energy Plan, as well as the receipt of government support such as subsidies for capital investment and research and development supporting the social implementation of innovative technologies. We also regard these initiatives as part of our social responsibility that extends beyond corporate boundaries, contributing to the building of a sustainable future.

Public Policy Engagement and Outcomes

The role of companies in realizing a sustainable society goes beyond business activities alone. As a member of the industrial sector, the JFE Group is actively involved in policy formation that contributes to the construction of a decarbonized society and actively engages in policy advocacy to promote effective institutional design.

The 8th GX Implementation Council

In February 2023, the cabinet approved the Basic Policy for the Realization of GX to simultaneously achieve three goals through GX: decarbonization, stable energy supply, and economic growth. In July of the same year, the cabinet also approved the Strategy for Promoting Structural Transition based on Decarbonization (GX Promotion Strategy). Growth-oriented Carbon Pricing (CP) Concepts is the decarbonization initiative based on this strategy and is currently being actively pursued toward its realization and implementation.

At the 8th GX Implementation Council, held in November 2023, JFE Steel’s President Kitano (then-Chairman of the Japan Iron and Steel Federation) explained the efforts being made by the Japanese steel industry to achieve carbon neutrality, and he called for long-term government support measures corresponding to the support provided by the government in Europe, the U.S., and China for the huge research and development and capital investment costs. He also expressed the need for long term government support for converting to innovative processes and dealing with the increase in operational costs for non-fossil fuels, electricity, and other sources, as actions for stimulating demand for green steel materials with high environmental value through, for example, public procurement, measures to ensure the international competitiveness of industrial electricity prices, and support for building new infrastructures, including a hydrogen supply chain and a CCS scheme.

These recommendations were reflected in the GX2040 Vision, approved by the cabinet in February 2025, in the form of visualizing GX value and active procurement of GX products and services, and positioned as concrete policies encouraging the formation of GX markets. The vision also clearly stated that GX investment will be advanced for hard-to-abate, high-emission industries such as steel, including conversion to innovative electric arc furnaces and introduction of steelmaking processes utilizing hydrogen.

56th Meeting of the Advisory Committee for Natural Resources and Energy’s Strategic Policy Subcommittee

The 56th Meeting of the Advisory Committee for Natural Resources and Energy’s Strategic Policy Subcommittee was held on June 6, 2024 to embark on formulating Japan’s 7th Strategic Energy Plan. At this meeting, JFE Holdings’ President Kitano gave a presentation entitled Energy Policy to Help JFE Steel Achieve Decarbonization, during which he recommended policies to promote the use of green steel products and energy policies to reduce uncertainty from the business environment related to GX.

The president announced a plan to make an investment decision during FY2024, assuming government support, on the process conversion to an innovative electric arc furnace under consideration at the Kurashiki District of the West Japan Works of JFE Steel, and expressed the intention to build a mass production system for high-quality, high-function green steel products that could not be produced with conventional electric arc furnaces. He also emphasized that policies to promote the use of green steel products are indispensable for Japanese manufacturing to enhance its international competitiveness in this area, in addition to measures supporting capital investment and operating costs. Challenges include the development and reconstruction of transmission infrastructure, establishing a stable supply system for decarbonized power sources, and developing a supply infrastructure for non-fossil fuels such as hydrogen and ammonia. He called for the government to proactively deploy policies and promote decarbonization as a national GX strategy to seize this opportunity to revitalize the Japanese economy.

These recommendations, in addition to the GX2040 Vision described above, were also confirmed to have influenced policy formulation, as the 7th Strategic Energy Plan, approved by the Cabinet in February 2025 explicitly stated the necessity of securing electricity supply capacity and strengthening power grids (including intra-regional trunk systems), developing supply infrastructure for non-fossil fuels, and promoting policies for introducing decarbonization technologies.

Study Group on Green Steel for GX

At the 3rd meeting of the Study Group on Green Steel for GX, hosted by the Ministry of Economy, Trade and Industry in November 2024, Hiroyuki Tezuka, Fellow of JFE Steel , spoke about the necessity of green steel, the status of formulating green steel guidelines in Japan and the World Steel Association, and policy advocacy activities at COP29 and other forums. He also introduced the status of rulemaking for the dissemination of green steel and emphasized the importance of assigning environmental value to emission reductions during the carbon-neutral transition period.

As mentioned above, as a result of these proposals, the summary of the Study Group clarified the definition of “green steel” for promoting GX and confirmed the government’s policy to prioritize measures such as preferential procurement and purchasing support for steel products that reflect the value of emission reductions in the steelmaking process. Specifically, beginning in FY2025, these policies will be implemented through updates to the criteria for products subject to preferential procurement under the Act on Promoting Green Procurement, as well as to the additional criteria for subsidies promoting the introduction of clean energy vehicles. These institutional reforms are driving market formation and demand expansion for green steel and represent an example of GX efforts by JFE Steel and the steel industry being reflected in national policy.

Overview of Government Support

Efforts to achieve carbon neutrality require both the research and development of innovative technologies and large-scale capital investment, which are beyond the capacity of companies to pursue on their own. The JFE Group is actively using policy support frameworks established under Japan’s GX initiatives to accelerate decarbonization.

Adoption under the Energy and Manufacturing Process Conversion Support Program for Industries in a Hard-to-Abate Sector

Realizing a carbon-neutral society in Japan while also reviving economic growth will depend upon reliably linking research and development outcomes to domestic capital investment. In particular, the practical application of decarbonization technologies in the steel industry requires massive investment accompanied by process conversion, without prospects for increased revenue through higher production volumes. For this reason, we have repeatedly emphasized the extreme difficulty for private companies to make such investment decisions on their own.

In light of this, the government established the Energy and Manufacturing Process Conversion Support Program for Industries in Hard-to-Abate Industries to subsidize a portion of the capital investment required for fuel conversion in in-house power generation facilities and the conversion of manufacturing processes that meet requirements such as CO2 reduction effects, in industries such as steel, chemicals, paper and pulp, and cement. This program uses GX transition bonds and aims to support both the practical realization of carbon neutrality and the strengthening of industrial competitiveness.

In addition, the tax credit for promoting domestic production in strategic sectors was introduced to promote domestic production in strategically important industries, including GX. The system is intended to enhance industrial competitiveness by providing tax credits to support fields such as green steel, where initial investment as well as production and sales costs are high.

In regard to the innovative electric arc furnace (high-efficiency, large-scale electric arc furnace) that we have been considering for introduction at the Kurashiki District of the West Japan Works during the transition period toward carbon neutrality, our project was selected under this program on December 20, 2024, and officially approved following the subsidy grant decision on April 9, 2025. In addition to the innovative electric arc furnace, new installations will include secondary refining equipment, cold iron logistics facilities, wharf development, and power receiving and distribution facilities. The total investment will amount to 329.4 billion yen, with government support capped at 104.5 billion yen. We plan to commence production in the first quarter of FY2028 and will promptly advance construction of the innovative electric arc furnace. Furthermore, we will enhance our supply capacity for green steel and strive to achieve both emission reductions and business growth by also using the support of the tax credit for promoting domestic production in strategic sectors.

Adoption Status for the Green Innovation Fund Projects

The JFE Group is fully leveraging the New Energy and Industrial Technology Development Organization (NEDO)’s Green Innovation Fund project, and we are conducting research and development in collaboration with other companies in the industry toward realizing carbon neutrality. JFE Steel is working on a NEDO project called Utilizing Hydrogen in Steelmaking Processes (GREINS), while JFE Engineering is focusing on carbon neutrality in the material cycles and waste management sector as well as on lowering the cost of offshore wind power generation.

Utilizing Hydrogen in Steelmaking Processes (GREINS)

JFE Steel formed a consortium with Nippon Steel Corporation, Kobe Steel, Ltd., and the Japan Research and Development Center for Metals and jointly commissioned the Utilizing Hydrogen in Steelmaking Processes (GREINS) project to achieve progress toward carbon neutrality by 2050. The project scale is approximately 573.7 billion yen*1, and the four companies involved are receiving a total of approximately 449.9 billion yen*2 of financial support.

- *1Source: Project summary document (May 24, 2024) on NEDO’s Utilizing Hydrogen in Steelmaking (GREINS) project

- *2This includes incentives subject to change depending on project progress and other factors at each stage gate.

COURSE50

In the area of developing hydrogen reduction technologies that use in-house hydrogen, we intend to achieve a 30% reduction of CO2 emissions through hydrogen reduction along with separation and capture of CO2 from blast furnace gases. The first facility is expected to come online by 2030, followed by other plants by 2050. JFE Steel is in charge of examining the combustion behavior of pulverized coal and reduction furnace gas and evaluating the entire process.

- Project scale: Approx. 72.7 billion yen*1, Financial support scale: Approx. 43.6 billion yen*2 (total for the four companies)

- *1The project scale is calculated based on the level of financial support and the subsidy rate.

- *2This includes incentives subject to change depending on project progress and other factors at each stage gate.

Carbon-Recycling Blast Furnaces

In the area of developing low-carbon technologies using CO2 contained in externally sourced hydrogen or blast furnace exhaust gas by developing and combining these technologies with other low-carbon techniques, such as using biomass and direct reduced iron as raw materials, we hope to achieve a greater than 50% reduction of CO2 emissions from the blast furnace steelmaking process by 2030 through the use of medium-scale test blast furnaces, which are larger than one-fifth the size of a full-scale furnace. JFE Steel is in charge of developing carbon recycling blast furnace operation technology and elemental technology as well as overall process evaluation and review, and in May 2025, a small-scale test blast furnace was fired up and began operation.

- Project scale: Approx. 285.3 billion yen*1, Financial support scale: Approx. 238.6 billion yen*2 (total for the four companies)

- *1Project scale is based on the level of financial support and subsidy rate.

- *2This includes incentives subject to change depending on project progress and other factors at each stage gate.

Direct Reduction Compact Bench Pilot Furnace

In the area of developing direct hydrogen reduction technology, we intend to demonstrate the method using medium-scale test blast furnaces, which are larger than one-fifth the size of a full-size furnace, applying a technology for directly reducing the CO2 emissions of low-grade iron ore with hydrogen by more than 50%, compared to the current blast furnace method, by 2030. JFE Steel is in charge of examining operational fluctuations and wide-ranging methanation reaction characteristics using the new bench pilot furnace, investigating reduction pulverization and gas composition that both suppresses clustering and achieves a high reduction rate, evaluating the microstructure using high-precision equipment, determining gas composition and the level of iron ore reduction and carbonization, and optimizing shape and forming. The bench test began operation in December 2024 and successfully produced direct reduced iron continuously from low-grade pellets using 100% hydrogen.

- Project scale: Approx. 136.9 billion yen*1, Financial support scale: Approx. 114.1 billion yen*2 (total amount for the four companies)

- *1Project scale based on the level of financial support and subsidy rate.

- *2This includes incentives subject to change depending on project progress and other factors at each stage gate.

Pilot Electric Arc Furnaces

In a project for developing impurity removal technology for electric arc furnaces using direct reduced iron, demonstrations of a large scale electric arc furnace process (processing capacity of approximately 300 tonnes) will be conducted to verify its control of the concentration of impurities (components affecting the product) to the same level as standard blast furnace methods (phosphorus 150 ppm, nitrogen 40 ppm or less), toward the goal of manufacturing high-grade steel suitable for car body panels and other components with the directly reduced iron made from low-grade iron ore. JFE Steel is in charge of evaluating and examining the new heat sources and scrap iron preheating using a small-scale test electric arc furnace with a capacity of 10 tonnes and developing technologies for dephosphorization and denitrification of molten steel using an ex-core refining furnace with a capacity of 3 tonnes. The small-scale pilot electric arc furnace began operation in February 2025, and development is making progress toward the stage gate scheduled for the end of FY2025.

- Project scale: Approx. 40.4 billion yen*1, Financial support scale: Approx. 30.6 billion yen*2 (total for the four companies)

- *1Project scale is calculated based on the level of financial support and subsidy rate.

- *2This includes incentives subject to change depending on project progress and other factors at each stage gate.

- NEDO: A new research focus under the Green Innovation Project: Hydrogen Utilization in Iron and Steelmaking Processes (Japanese only)

- NEDO: Hydrogen Utilization in Iron and Steelmaking Processes

- Consortium of the Green Innovation Fund Project: Utilizing Hydrogen in the Steelmaking Process

Carbon Neutrality in the Material Cycles and Waste Management Sector

A project titled “Achieving Carbon Neutrality in the Waste and Resource Circulation” is underway as part of the Green Innovation Fund project administered by the New Energy and Industrial Technology Development Organization (NEDO). According to NEDO, this project is intended to minimize atmospheric emissions of carbon dioxide, methane, and other gases from waste incineration and landfill disposal, and to stably and efficiently recover carbon from waste to achieve net zero GHG emissions. It also involves development and demonstration for realizing a carbon-neutral carbon circulation system that circulates and supplies biomass-derived carbon as an industrial resource, with the goal of creating a model for social implementation.

JFE Engineering, together with Sekisui Chemical Co., Ltd. , proposed a project titled Waste-to-Chemical technology development for Green Ethanol production by integration of Advanced Gasification and Biochemical Conversion technologies, in response to NEDO’s call for proposals under the Green Innovation Fund Project/Achieving Carbon Neutrality in Waste and Resource Circulation, and the proposal was selected.

For details on this project, please refer to:

Efforts to Lower the Cost of Offshore Wind Power Generation

A project on “Cost Reductions for Offshore Wind Power Generation” is underway as part of the Green Innovation Fund project administered by the New Energy and Industrial Technology Development Organization (NEDO). According to NEDO, the aim is to achieve early cost reductions, primarily in floating offshore wind power generation, and to promote wider introduction, drawing on knowledge gained from this project and previous demonstration initiatives.

Through the consortium in which it participates, JFE Engineering jointly proposed and was selected for NEDO’s Green Innovation Fund Project/Cost Reductions for Offshore Wind Power Generation/Floating Offshore Wind Power Demonstration Project (Phase 2) under the theme: “Southern Akita Floating Offshore Wind Demonstration Project Aimed at Overseas Expansion via Cost Reductions.”

For further details, please refer to:

Funding Methods through Green/Transition Finance

JFE Holdings has established the Green/Transition Finance Framework and issued transition bonds through a public offering in 2022, which was selected as the first model example in the iron and steel sector under METI’s Transition Finance Model Projects in FY2021. Achieving carbon neutrality will require significant, long-term investments in capital and R&D. JFE Holdings will continue to leverage transition financing and diversify its funding methods.

Formulated the Technology Roadmap for Transition Finance in the Iron and Steel Sector

The technology roadmap for Transition Finance toward decarbonization in the iron and steel sector, published by the Japanese Ministry of Economy, Trade, and Industry (METI), outlines a path for accelerating decarbonization and achieving carbon neutrality by introducing innovative technologies, with the same assumption that social infrastructure such as hydrogen supply and CCUS will be in place by the 2040s. In the process of drawing up this roadmap, JFE Steel’s Fellow, Hiroyuki Tezuka, a member of the Japan Iron and Steel Federation’s Energy Technology Committee, participated as a specialist in the task force formulating the roadmap. The roadmap is aligned with Japan’s nationally determined contribution (NDC) based on the Paris Agreement and is therefore aligned with the agreement.

Green/Transition Finance Framework

The JFE Group developed this framework based on the “Green Bond Principles 2021” of the International Capital Market Association (ICMA), the “Green Loan Principles 2023” of the Loan Market Association (LMA), the Asia Pacific Loan Market Association (APLMA), the Loan Syndication & Trading Association (LSTA), the “Green Bond Guidelines (2022),” the “Green Loan Guidelines (2022)” of the Ministry of the Environment, the “Climate Transition Finance Handbook 2023” of the ICMA, and the “Basic Guidelines on Climate Transition Finance (May 2021)” of the Financial Services Agency, the Ministry of Economy, Trade and Industry, and the Ministry of the Environment. Since our initiatives have been certified by a third-party organization as being aligned with METI’s roadmap, this framework of the JFE Group is also aligned with the Paris Agreement.

- METI: Technology Roadmap for Transition Finance in the Iron and Steel Sector

- METI: Transition Finance Case Study

- Green/Transition Finance Framework (Japanese only)

- Transition Finance Report—Funds Raised, Allocated, and Their Impact (Japanese only)

Participation in External Initiatives

The JFE Group is taking responsible action toward realizing a sustainable society in response to global environmental issues such as climate change. As part of this effort, we are actively participating in major domestic and international initiatives, enhancing our ability to respond to climate change through the sharing of knowledge and collaboration. The following are the main initiatives in which we participate.

Participation in the GX League

The Ministry of Economy, Trade and Industry has established the GX League, a forum that invites companies to work on GX; take up the challenge of GX in cooperation with the government, academic, and economic sectors; discuss how to transform the overall economic and social system; and drive the creation of new markets. Understanding that the league’s objectives aligned with the JFE Group’s overall approach to addressing climate change, JFE Steel has been taking part in the GX League since its establishment.

In working with the GX League, JFE Steel has been actively participating in the Rule Working Group (WG), a forum for public-private rulemaking to foster new markets and pursuing the creation and expansion of the market for GX products.

FY2023 Initiatives

JFE Steel participated in the Working Group for Adding Value to Green Products , and in December 2023, the WG published the document: How to Add Value to Green Products. The document recognizes that, in terms of corporate investment in decarbonization, it is critically important to quantify and communicate the value of emission reductions achieved through a company’s own initiatives and ensure that this value is recognized in global markets. It also presents draft guidelines for enhancing the added value of green products and outlines pioneering projects, including JFE Steel’s JGreeX initiative, and introduces methods for measuring and calculating green value, allocating it effectively, and utilizing it in economic activities. Furthermore, reflecting the concepts presented in the document, the Interim Summary of the Study Group on the GX Product Market Contributing to Demand Creation for Strengthening Industrial Competitiveness and Achieving Emission Reductions , published by the Ministry of Economy, Trade and Industry in March 2024, suggested “Reduced Emissions of Product” as a new GX value.

- Final Report for the GX League (Japanese only)

- Document on how to Add Value to Green Products (full version, in Japanese only)

- Document on how to Add Value to Green Products (summary version, in Japanese only)

FY2024 Initiatives

JFE Steel participated in the GX Product Social Implementation Promotion WG . Following work group discussions in December 2024, the Ministry of Economy, Trade and Industry recently established the GX Acceleration Declaration to support companies engaged in creating the GX market. This framework is intended to visualize companies proactively working on the social implementation of GX products and services and establish a self-declaration mechanism for appropriately evaluating these efforts. Companies make voluntary declarations on procuring GX products as well as disclosing and evaluating their content.

JFE Steel was among the first to make a declaration after the framework was established. In addition to supplying green steel, we declared the procurement of GX products on the demand side as well, thereby playing a role in stimulating demand.

- METI: GX Acceleration Declaration Framework Newly Launched as Effort to Encourage Companies Proactively Engaging in Creation of a Market for GX

- JFE Steel GX Acceleration Declaration (Japanese only)

Investment in the GX Acceleration Agency

The GX Acceleration Agency is a certified corporation established in April 2024 by the Ministry of Economy, Trade and Industry, as stipulated in the Act on Promoting a Smooth Transition to a Decarbonized Growth-oriented Economic Structure. In order to achieve GX investment of over 150 trillion yen over the next 10 years, the GX Acceleration Agency will provide financial support as debt guarantees, operate a carbon emissions trading system, and collect fossil fuel surcharges. JFE Holdings invested in the GX Acceleration Agency at the time of its establishment.

TCFD Consortium

The TCFD Consortium was established in 2019 as a forum for companies and organizations that support the TCFD recommendations to discuss effective climate-related disclosures and ways for financial institutions to make appropriate investment decisions based on them.

Guidance on Climate-related Financial Disclosures 2.0 (TCFD Guidance 2.0) and TCFD Guidance 3.0 were published as outcomes of the consortium in 2020. In 2021, the consortium also published the Transition Plan Guidebook, which outlines the basic concepts and approaches to transition plans as part of the implementation of TCFD recommendations.

JFE Holdings supports the recommendations of the final TCFD report and participates in this consortium.

United Nations Global Compact

The JFE Group has signed the United Nations Global Compact, the world’s largest sustainability initiative advocated by the United Nations, and has declared its support. We are committed to complying with and implementing the Ten Principles of the Global Compact and promoting the SDGs in order to realize a sustainable society. The JFE Group is also a member of the Global Compact Network Japan, the local network of the Global Compact. Having identified “Contribute to resolving climate change issues” as a material issue, the JFE Group is working to reduce CO2 emissions. We also draw on the decarbonization initiatives of other participating companies to further advance efforts to reduce CO2 emissions across the JFE Group and society as a whole.

SPEED Research Group

The SPEED (Special Project on Eco-innovation and Eco-business for Sustainable Development) Research Group contributes to the development of eco-innovations and eco-businesses through industry-academia-government collaboration and international cooperation. JFE Holdings participates in this research group and is involved in activities such as information sharing and opinion exchange with government, universities, research institutions, and companies.

EN Japan Climate Leaders’ Partnership (JCLP)

JFE Engineering is a member of the Japan Climate Leaders’ Partnership (JCLP). Established in 2009, the JCLP is a coalition of Japanese corporations that encourage the industrial community to fully recognize the urgency of climate change and take more decisive action to create a sustainable, decarbonized society. Companies fulfill their corporate responsibility by demonstrating leadership in the transition to a decarbonized society. The Company is participating in the Decarbonization Consortium, JCLP’s platform for encouraging information sharing and collaboration between companies and is actively engaged in creating opportunities to learn from companies at the frontline of decarbonization efforts, and collaborating with other companies to create new solutions.

Japan’s Steel Industry Initiatives

Japan Iron and Steel Federation (JISF) Initiatives

Long-term Vision for Climate Change Mitigation

JFE Steel is proactively engaged in a variety of activities as a member of the Japan Iron and Steel Federation (JISF). The JISF has been focusing on achieving the goals for 2020 under its Commitment to a Low Carbon Society (renamed the Carbon Neutrality Action Plan in FY2021). Furthermore, in November 2018, the JISF formulated and published its Long-term Vision for Climate Change Mitigation for 2030 and beyond, with JFE Steel playing a central role in its development. This document lays out the industry’s challenge for realizing zero-carbon steel and explains the pathway for achieving the 2°C scenario for steelmaking and the necessity of ultra-innovative technologies to achieve the 1.5°C scenario. Also, on February 15, 2021, the JISF announced the “Basic Policy of the Japan steel industry on 2050 Carbon Neutrality sought by the Japanese government,” declaring that the Japanese iron and steel industry will boldly accept the challenge of realizing zero-carbon steel.

JISF’s Carbon Neutrality Action Plan

In February 2021, the JISF declared that the Japanese steel industry will boldly take on the challenge of realizing carbon neutrality. The Plan on Commitment to a Low Carbon Society was amended and renamed as the Carbon Neutrality Action Plan, and the Phase II target (2030 target) was revised. In the Eco Process of the plan, an ambitious 2030 target was set taking into account new perspectives such as the expansion of scrap use as well as the maximum introduction of best available techniques (BATs) based on energy efficiency already among the highest in the world.

Regarding Eco Product, which is intended to reduce GHG emissions at the product use stage, high-performance steel is expected to play a particularly major role in the promotion of offshore wind power and electrification of automobiles, which are among the 14 fields of the government’s Green Growth Strategy. Accordingly, the Japanese initiative will accelerate practical global warming measures from a global perspective by making visible the conventional quantitative evaluation of the five types of high-performance steel.

As for Eco Solutions, the JISF will develop a system for introducing appropriate technology for transferring and spreading the production process for decarbonized steel in the Asian regions, where steel production is expected to expand. Furthermore, regarding Innovative Technology Development, the JISF will take on the challenges of technologies such as direct hydrogen reduction and high-performance steel production using electric arc furnaces under the Green Innovation Fund, in addition to COURSE 50 and ferro-coke.

Overview of the Carbon Neutrality Action Plan

Eco Process

Cut energy-related CO2 emissions (total volume) in FY2030 by 30% compared to the FY2013 level by adopting BATs to promote energy conservation, using waste plastics, adopting innovative technologies that are currently under development and scheduled to be in use around 2030, and using raw fuel with less CO2 emissions.

Eco Product

Contribute to CO2 emissions reduction by domestically and internationally supplying high-performance steel. This steel will reduce CO2 emissions when used in the final product. The reduction potential in 2030 is estimated to be approximately 42 million t-CO2 for the five steel products that have been quantitatively evaluated for their contribution to reducing emissions.

Eco Solution

Contribute to reducing CO2 emissions worldwide by transferring and spreading the Japanese steel industry’s advanced energy-saving technologies and facilities to the world’s steel industry. Estimated contribution on CO2 emissions reduction is 80 million t-CO2 in 2030.

Innovative Technology Development

Contribute to carbon neutrality by boldly developing technologies in the following four areas.

- Hydrogen reduction technology using in-house hydrogen

- Low-carbon technology using CO2 contained in externally sourced hydrogen or blast furnace exhaust gas

- Direct hydrogen reduction technology

- Impurity removal technology for electric furnace using direct reduced iron

Assessment of the FY2023 Carbon Neutrality Action Plan (Phase II) Results (JISF)

Total volume of energy-related CO2 emissions in FY2023 was 148.35 million tonnes, a decrease of 46.08 million tonnes, or 23.7%, compared to FY2013. The achievement rate of the FY2030 target (to reduce by 30% from FY2013) has reached 79.0%. Energy-related CO2 emissions and energy consumption are both declining, given continued energy saving efforts.

While the energy efficiency of the Japanese steel industry is among the highest in the world, vigorous efforts are made to promote greater energy savings by having businesses engaged in this effort draw upon subsidies to promote investment in saving energy and other actions.

Reduced CO2 Emissions through High-Performance Steel Materials (Effects of Eco-Products)

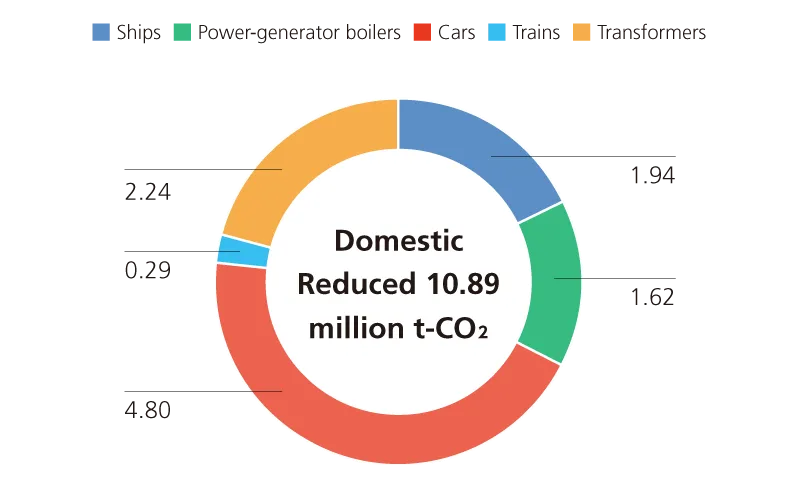

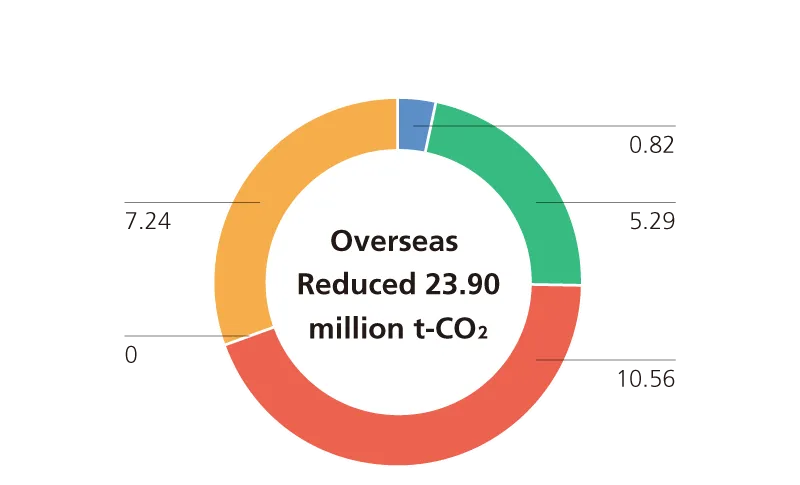

The Japan Iron and Steel Federation (JISF) estimates the CO2 emissions reduction impact of using high-performance steel materials. It is estimated that the use of five major high-performance steel materials in cars, transformers, ships, power generation boilers, and trains in Japan and overseas* (FY2023 production: 3.85 million tonnes, 4.7% of crude steel production) helped reduce CO2 emissions by 35.16 million tonnes (11.00 million tonnes in Japan, 24.16 million tonnes overseas) in FY2023.

- *Calculations made by the Institute of Energy Economics, Japan. The five materials are steel sheets for automobiles, grain-oriented electrical steel sheets, thick steel sheets for shipbuilding, steel tubes for boilers, and stainless steel sheets. FY1990 is the reference point for domestic reduction figures, with FY2003 as the reference point for the overseas reduction figures for automobiles and ships, FY1998 for steel pipes for boilers, and FY1996 for electrical steel sheets.

CO2 Reduction Resulting from the Use of Five High-Performance Steel Materials in Japan and Overseas (FY2023)

Related Links

- The Japan Iron and Steel Federation (JISF): Climate Change Policy page

- The Japan Iron and Steel Federation (JISF): LCA of Steel Products page

- The Japan Iron and Steel Federation (JISF): Publication of ISO 20915

- The Japan Iron and Steel Federation (JISF): Publication of JIS Q 20915

- The Japan EPD Program by SuMPO

Industry-Academia Collaboration Initiatives

The JFE Group is actively engaged in joint research and collaboration with universities to strengthen scientific and practical responses to climate change. We are incorporating the latest knowledge and technologies through partnerships with academic institutions and advancing efforts toward realizing a sustainable society. Below are some of the main initiatives we are pursuing in collaboration with universities.

The University of Tokyo and 16 Organizations Announce Launch of Joint Research Initiative to Achieve a Carbon-Neutral Society Establishment of the Social Collaboration Program “Materials for Future Energy Infrastructure Trust (MEIT) ”

JFE Steel, JFE Engineering, and 16 organizations−including the University of Tokyo, IHI Plant Services Corporation, INPEX CORPORATION , ENEOS Xplora Inc , Kanadevia Corporation , Kawasaki Heavy Industries, Ltd. , Kobe Steel, Ltd., JERA Co., Inc., TOKYO GAS NETWORK Co., Ltd. , Namura Shipbuilding Co., Ltd. , NIPPON STEEL ENGINEERING CO., LTD ., NIPPON STEEL PIPELINE & ENGINEERING CO., LTD ., NIPPON STEEL CORPORATION , Nippon Kaiji Kyokai (ClassNK), and Mitsubishi Heavy Industries, Ltd. have jointly established the Social Collaboration Program*, Materials for Future Energy Infrastructure Trust (MEIT), to scientifically elucidate and standardize the material reliability of energy infrastructure that supports a carbon-neutral society. The joint research will commence on May 1, 2025. JFE Steel, Kobe Steel, Ltd., NIPPON STEEL CORPORATION, and Nippon Kaiji Kyokai serve as the managing institutions for this program.

The purpose of the program is to evaluate the reliability of materials used in energy infrastructure and storage systems for decarbonized energy carriers such as liquefied hydrogen and ammonia, as well as in liquefied and high-pressure CO2 in carbon capture and storage (CCS) projects. Through these efforts, the initiative seeks to accelerate the development of energy infrastructure for a carbon-neutral society, meet domestic demand, and strengthen international competitiveness.

- *A collaborative research framework between the University of Tokyo and 16 organizations, operated with joint research expenses borne by the companies under contractual agreements with the university. This program facilitates interdisciplinary collaboration among researchers and the formation of research teams to address comprehensive societal challenges, thereby overcoming the limitations of conventional one-on-one collaborations between researchers and companies.

Overview of the Social Collaboration Course

As society transitions to carbon neutrality, energy infrastructure is shifting significantly from fossil fuels to new systems based on hydrogen and ammonia. This includes liquefied hydrogen tanks, ammonia tanks, CO2 tanks, and high-pressure CO2 pipelines, all of which require material reliability evaluations to ensure long-term safety and economic viability. The program will establish material selection criteria, post-weld heat treatment omission standards, and fracture prevention criteria to optimize infrastructure construction costs and promote international standardization that contributes to a sustainable energy society.

Program Name: Social Collaboration Program “Materials for Future Energy Infrastructure Trust (MEIT)”

Period: May 1, 2025-April 30, 2030

Joint Research Topics:

- Development of fracture evaluation technologies and standards for large-scale liquid ammonia tanks (stress corrosion cracking prevention and omission of post-weld heat treatment).

- Development of fracture evaluation technologies and standards for large-scale liquid CO2 tanks (omission of post-weld heat treatment).

- Establishment of rapid ductile fracture prevention standards for high-pressure CO2 pipelines in CCS projects.

- Enhancement of reliability and evaluation technologies for next-generation materials (cost-effective stainless steel and low-nickel steel) for large-scale liquid hydrogen tanks.

Collaborating Faculty: School of Engineering, University of Tokyo

ST JFE Steel and Tohoku University’s Collaborative Research Laboratory for Green Steel

In February 2022, JFE Steel and Tohoku University jointly established the Collaborative Research Laboratory for Green Steel within the university’s Graduate School of Engineering to research eco-friendly steel materials and production methods for the carbon-neutral era. The Collaborative Research Laboratory is managed under a cross-divisional system and develops collaborations across a wide range of fields, including the development of steelmaking processes and materials. This will facilitate a multifaceted approach to resolving issues related to low-carbon steelmaking processes and to discover innovative development themes from new perspectives. Furthermore, we will dispatch young researchers to nurture highly specialized human resources who will lead the next generation of the steelmaking industry.

EN JFE Engineering Carbon Neutrality Collaborative Research Center Established at the Institute of Science Tokyo

JFE Engineering and the Institute of Science Tokyo*1 opened the JFE Engineering Carbon Neutrality Collaborative Research Center (CRC) at the Institute’s Laboratory for Zero-Carbon Energy under the former Tokyo Institute of Technology (currently the Institute of Science Tokyo) on July 1, 2022. The purpose of the CRC is to promote new technologies for realizing a carbon-neutral society. The two parties are comprehensively and jointly working on technical developments in carbon neutrality, transcending the boundaries of a typical individual joint research framework in a multilayered approach to generate innovation across the wide range of fields required for realizing a carbon-neutral society.

The CRC will promote the development of new technologies to help realize a carbon-neutral society by combining JFE Engineering’s engineering technologies related to plant and infrastructure construction in the fields of energy and the environment with the Institute of Science, Tokyo’s advanced academic knowledge across a wide range of areas. The CRC will also continue collaborating with a variety of organizations through the Tokyo Tech GXI*2, an industry-academia partnership project run by the Institute of Science Tokyo.

- *1Tokyo Institute of Technology and Tokyo Medical and Dental University were integrated in October 2024.

- *2Intended to promote research activities that will initiate a Green Transformation (GX) society, strengthen startups, and substantiate industry-society collaboration.

Global Scale Initiatives

Global Actions to Address Global Warming

WSA Climate Action Data Collection Programme certification

ISO 14404 is an international standard proposed by the Japan Iron and Steel Federation (JISF) to the International Organization for Standardization (ISO) as a methodology for the globally unified calculation of CO2 intensity from iron and steel production, to ultimately assess the energy efficiency of steelworks. The Japanese steel industry is addressing global warming through international public-private collaborations, including ISO 14404-based assessment of steelworks in developing countries and recommending specific technologies best suited to India and ASEAN countries. It is continuing this effort together with the Ministry of Economy, Trade and Industry (METI) in order to enhance ISO 14404 so it can be applied to steel manufacturing facilities with more complex structures.

JFE Steel is also addressing global warming by participating in international activities, such as the Japan-India Public and Private Collaborative Meeting, the Japan-ASEAN Steel Initiative, and the Japan-China Steel Industries Exchange. In addition, JFE Steel is a member of the World Steel Association’s Climate Action Data Collection Programme, which uses ISO 14404 as the standard for measurement and calculation.

Efforts to Assess the Environmental Impact of the Excellent Recyclability of Steel Products

Life Cycle of Steel Materials

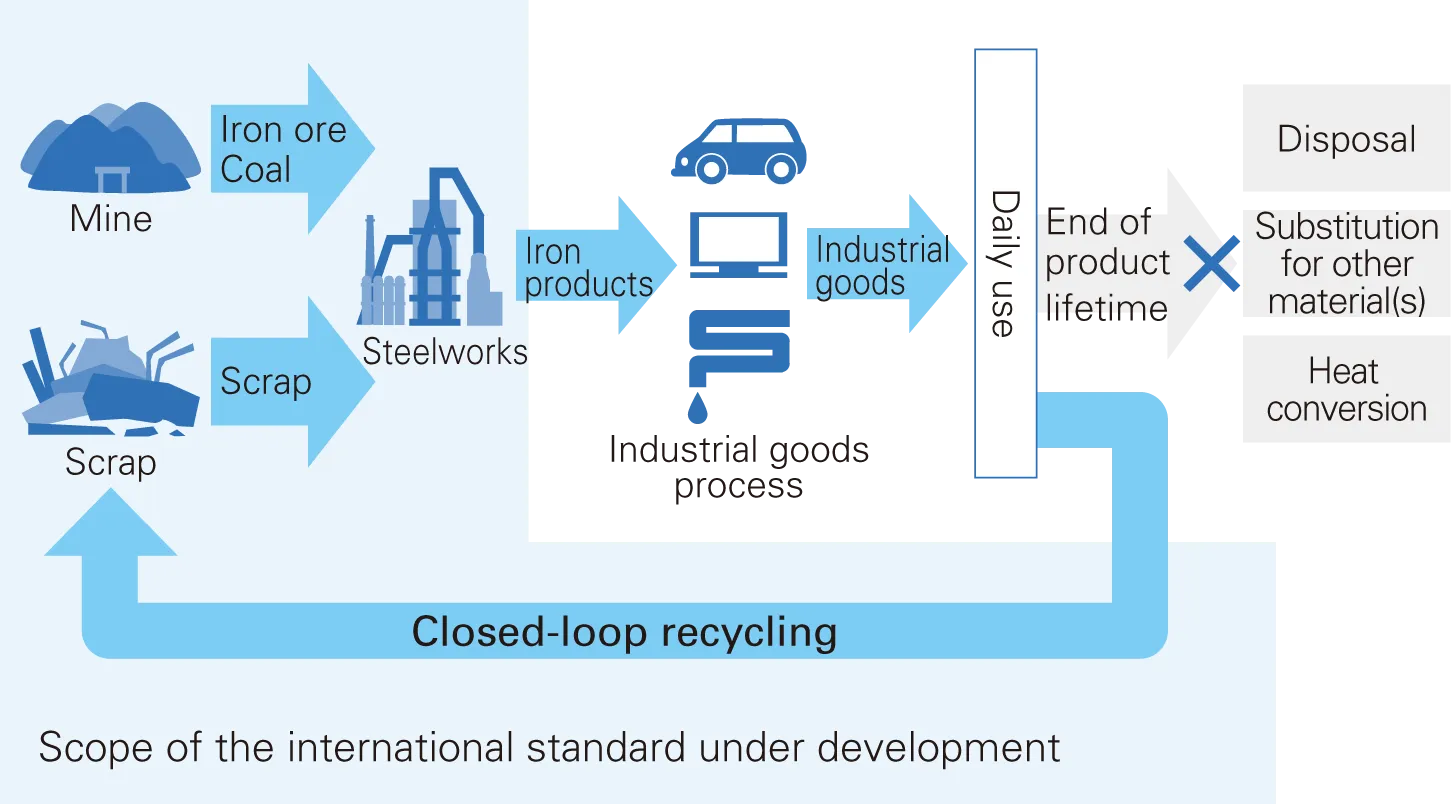

Accurately evaluating the environmental impact of products requires assessment and quantification of impact over their entire life cycles, from raw resource mining to material production, product manufacture, use, and final disposal. Life cycle assessment (LCA) is one evaluation method.

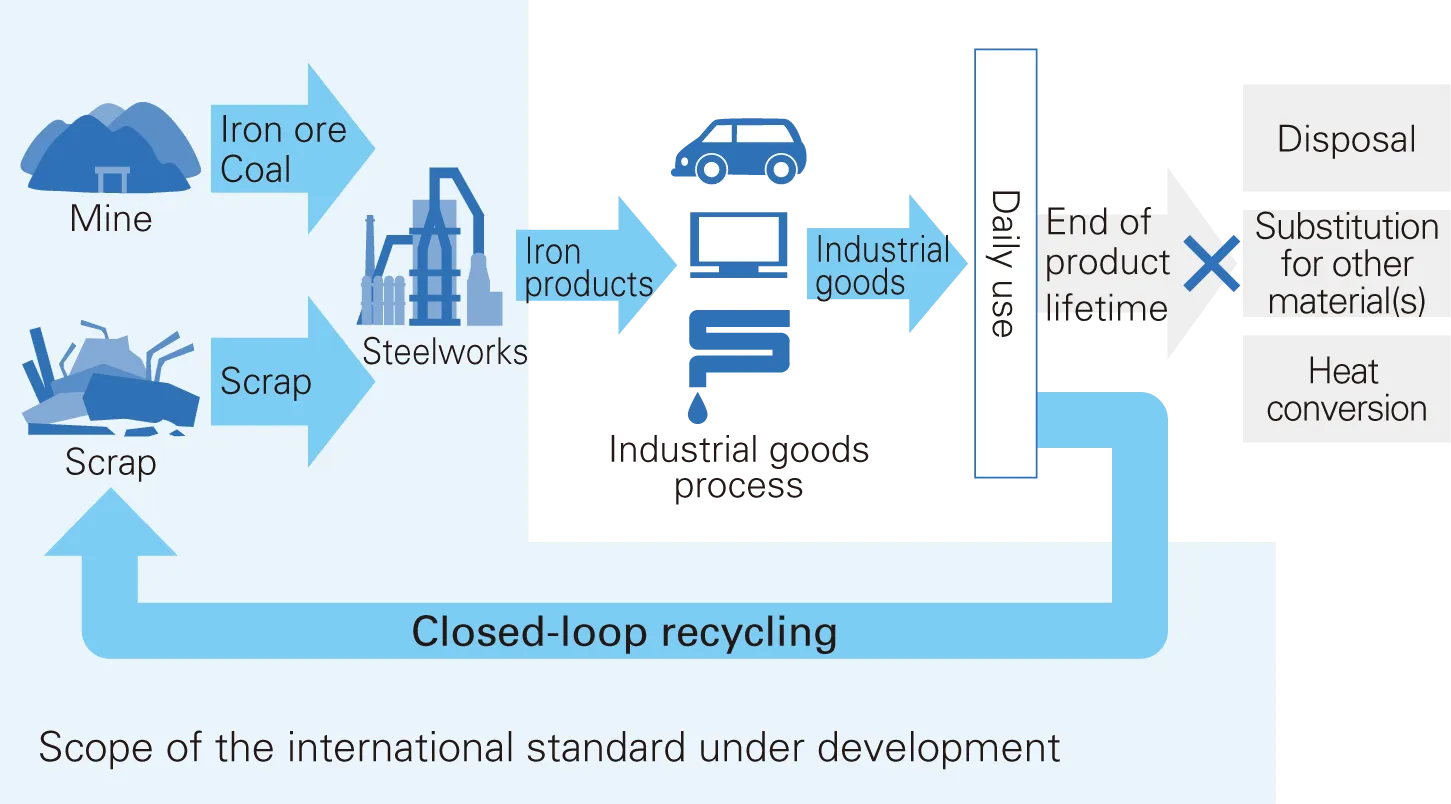

After final products such as automobiles and buildings finish their mission in society, all of their steel components can be recycled and reused. Closed-loop recycling is an excellent characteristic of steel materials. From the perspective of LCA, steel can be viewed as having an extremely low environmental impact compared to other materials.

JFE Steel played a major role in the development of ISO 20915 (Life Cycle Inventory Calculation Methodology for Steel Products) and JIS Q 20915 (Life Cycle Inventory Calculation Methodology for Steel Products), initiatives led by the Japan Iron and Steel Federation (JISF), which takes into account the impact of recycling and provides life cycle inventory (LCI) calculation methods specific to steel products.

In addition, 15 Japanese manufacturers of blast furnaces and electric arc furnaces joined forces to calculate the Japanese average for LCI of different steel products. Calculations based on their FY2018 operational data were also published.

JFE Steel acquired SuMPO EPD certification for 36 product types under the SuMPO Environmental Label Program under the Sustainable Management Promotion Organization (SuMPO). These cover three types of tinplate steel sheets for cans, nine flat steel products, nine construction steel products, three types of steel plates (steel plates for marine structures and wind power, shipbuilding steel plates, and UOE pipes), four steel pipe products, and eight bar and wire rod products. We will continue to make use of SuMPO EPD labels to help customers protect the environment and strengthen communications with them.

Japan-Korea Green Steel Joint Seminar

The 2nd Japan-Korea Green Steel Joint Seminar was held in Tokyo on October 23, 2024, jointly organized by the Japan Iron and Steel Federation and the Korea Iron and Steel Association. The seminar was attended by representatives from both countries, including Masaaki Izumiyama, Chairman of the International Environmental Strategic Committee, the Japan Iron and Steel Federation (Nippon Steel Corporation), and Kwang-young Lee, Executive Managing Director of the Korea Iron and Steel Association, as well as guests of honor, including Manabu Nabeshima, Director of the Metals Division of the Ministry of Economy, Trade and Industry of Japan , and Seungjin Ko, Senior Deputy Director/Team Leader of the Steel Division, Metals and Ceramics Policy Division, Ministry of Trade, Industry and Energy of the Republic of Korea. A total of 53 participants, mainly from government organizations, steel companies, and academia in both Japan and South Korea, exchanged opinions on wide-ranging topics related to carbon neutrality in the steel industry.

Public and Private Collaborative Meeting between Indian and Japanese Iron and Steel Industry

The Japan Iron and Steel Federation has held the Public and Private Collaborative Meeting between Indian and Japanese Iron and Steel Industry annually since 2011 with support from the Ministry of Economy, Trade and Industry, and JFE Steel attends this meeting every year. The purpose of this meeting is to apply the technology and experience of Japan’s steel industry, which boasts the world’s highest energy efficiency, to recommend policies on energy conservation and environmental protection to the Indian steel industry and promote the transfer of energy-saving and environmental protection technologies from Japan.

The FY2024 meeting was held in New Delhi, India, on January 21, 2025, with support from the Economic Research Institute for ASEAN and East Asia (ERIA) . The meeting was moderated by Hiroyuki Tezuka, Secretary of the International Environmental Strategy Committee of the Japan Iron and Steel Federation and Fellow of JFE Steel. Participants included Shumpei Takagi, Deputy Director of the Metals Division of the Ministry of Economy, Trade and Industry of Japan; Vinod Kumar Tripathi, Additional Secretary of the Ministry of Steel of India ; and Nuki Agya Utama, Director of Energy Policy and Head of the Asia Zero Emission Center at ERIA . About 40 participants, mainly from government organizations and steel companies in both Japan and India, engaged in lively discussions on topics related to carbon neutrality in the steel industry of both countries. JFE Steel will continue to play a major role in this meeting and contribute to CO2 reduction in India by transferring Japanese energy-saving technologies.

ASEAN-Japan Steel Initiative

In May 2014, the Japan Iron and Steel Federation and the ASEAN Iron and Steel Council (AISC) signed a memorandum of understanding to promote regional collaboration the areas of the environment, standardization, and trade. The ASEAN-Japan Steel Initiative (AJSI) was launched as a public-private environmental effort to strengthen cooperation in environmental and energy saving efforts in ASEAN countries. As part of its activities, the initiative developed a Technologies Customized List (electric arc furnaces) as well as a Technologies Customized List (blast furnaces), which include energy-saving, environmental protection, and recycling technologies for electric arc furnaces and blast furnaces suitable for the ASEAN steel industry.

On November 20, 2024, the AJSI Seminar was held in person for the first time in about four and a half years, as an AJSI activity. The event was co-hosted with the Economic Research Institute for ASEAN and East Asia (ERIA) and held as part of the Southeast Asia Iron and Steel Institute (SEAISI) event “2024 ASEAN Iron and Steel Forum: Sustainable Steel and Green Construction” in Bangkok, Thailand, from November 18 to 21. Participants included Koji Takahashi, Director of the Metals Division of the Manufacturing Industries Bureau, Ministry of Economy, Trade and Industry of Japan , Naoto Okura, Director of Research and Policy Design at ERIA, and Wee-Jin Yeoh, Secretary General of SEAISI.

At the seminar, representatives from Japan and ASEAN countries introduced initiatives and prospects for policies and technologies for carbon neutrality as well as challenges and initiatives faced by steel manufacturers.

Japan-China Steel Industry Environmental Protection and Energy Conservation Technology Conference

This conference has been held since 2005, based on the memorandum of understanding that was signed at the Japan-China Steel Industry Environmental Protection and Energy Conservation Technology Conference, held in Beijing in July 2005 with the participation of top executives from both countries’ steel industries. The purpose of the conference is to raise the level of environmental conservation and energy saving in both countries through information exchanges between technical experts from steel manufacturers in Japan and China. The importance of this conference has been growing as it helps to promote not only sound development of the steel industry in both countries but also the effective use of resources and environmental conservation.

The FY2024 event was held in Wuhan, China, in March 2025, with roughly 80 participants from both countries’ steel industries. Representatives from both sides presented the status of actions toward carbon neutrality, energy conservation, CO2 reduction, and environmental protection, and actively exchanged information and opinions on topics of shared interest in both countries’ steel industries, such as green steel. JFE Steel will continue to participate in this conference to contribute to global carbon neutrality, energy saving, environmental action, and the sustainable development of the steel industry.

Lecture Events (Japan)

The JFE Group delivers lectures at various events to increase awareness of our efforts to combat climate change.

-

Lecture “JFE Group Environmental Vision for 2050 — Toward the Realization of Carbon Neutrality” at the Japan Auto Parts Industries Association Date Lecturer Hiroyuki Tezuka (Fellow, JFE Steel Corporation) -

Lecture “JFE Steel’s Initiatives for Achieving Carbon Neutrality and the Challenges” at the 8th Japan-France Green Finance Forum Date Lecturer Hiroyuki Tezuka (Fellow, JFE Steel Corporation) -

Lecture “JFE Steel’s Initiatives for Achieving Carbon Neutrality and the Challenges” at the JPI (Japan Planning Institute) Seminar Date Lecturer Hiroyuki Tezuka (Fellow, JFE Steel Corporation) -

Lecture “Latest Technology in Energy and Environment in the Steel Industry and Measures against Global Warming” in the Institute of Science Tokyo’s Advanced Course in Science and Technology in Energy and Environment Date Lecturer Ikufumi Sumi (Leader, Global Environment Team, Green Transformation Strategy, JFE Steel Corporation) -

Lecture “The Path to Decarbonization of Steel — Green Steel Contributing to the Green Transition” at the Kyoto University Graduate School of Management Energy Industry Seminar Date Lecturer Ikufumi Sumi (Leader, Global Environment Team, Green Transformation Strategy, JFE Steel Corporation) -

Lecture “Carbon Neutrality Initiatives” at the Bingo Urban Roundtable Lecture Meeting Date Lecturer Hiroyuki Tezuka (Fellow, JFE Steel Corporation) -

Lecture “JFE Steel’s Initiatives for Achieving Carbon Neutrality and the Challenges” at the APAC Financial Institutions Summit 2024 - Banking Date Lecturer Hiroyuki Tezuka (Fellow, JFE Steel Corporation) -

Lecture Green Steel Guidelines, published under “Steel Industry Green Steel Initiatives” on the Japan Iron and Steel Federation’s website Date of publication URL https://www.jisf.or.jp/business/ondanka/kouken/greensteel/documents/JISFGSguidelinev3.1final.pdf

Lectures Held Overseas

The JFE Group provides lectures at various events to raise awareness overseas of our efforts to address climate change.

-

Lecture “Fuel, Power, and Steam Supply-Demand Guidance System at Steelworks” at the 15th Japan-China Steel Advanced Technology Exchange Meeting for Environmental Protection and Energy-saving Meeting Date Lecturer Katsunari Suzuki (Cyber-Physical System R&D Department, Steel Research Laboratory, JFE Steel Corporation) -

Lecture “Efforts to Promote Green Steel — JISF Green Steel Guidelines, worldsteel Chain of Custody Guidelines” at the Japan-India Public and Private Collaborative Meeting Date Lecturer Yoshitsugu Suzuki (Global Environment Team, Green Transformation Strategy, JFE Steel Corporation) -

Lecture “Global Steel Decarbonization Initiatives — Necessity of Green Steel and Methodology of GHG Emission Assessment” at the ASEAN Japan Steel Initiative (AJSI) Seminar Date Lecturer Yoshitsugu Suzuki (Global Environment Team, Green Transformation Strategy, JFE Steel Corporation) -

Lecture “The Path to Decarbonization of Steel — Green Steel Contributing to the Green Transition” at the COP29 Japan Pavilion, Side Event Hosted by the Japan Iron and Steel Federation Conference: COP29 Date of presentation Lecturer Hiroyuki Tezuka (Fellow, JFE Steel Corporation) URL https://www.jisf.or.jp/news/topics/20241018.html

Evaluation of Alignment with Major Organizations

The JFE Group participates in various industry and economic organizations with the aims of realizing a sustainable society and enhancing corporate value. Through these affiliations, we pursue policy recommendations, share information, and address industry-wide challenges while fulfilling the social responsibilities associated with the business activities of our operating companies. The evaluation of alignment between the policies of major organizations in which the JFE Group participates and JFE’s stance is presented below along with the results.

Summary of Evaluation Results

We evaluated the consistency of the main recommendations and activities published by each organization with our aforementioned views and stance. As a result, we confirmed that the policies, stances, and policy recommendations clarified by each organization are aligned with our own views and stance. Going forward, we will continue to encourage constructive dialogue and exchanges of opinions with these organizations to ensure that our views and stance are reflected in the activities conducted by the organizations we belong to as members.

| Organization / Policy | GX Policies | Energy Policy | Carbon Pricing | Creation of GX Product Markets |

|---|---|---|---|---|

| The Japan Iron and Steel Federation | Aligned | Aligned | Aligned | Aligned |

| World Steel Association | Aligned | Aligned | Position yet to be expressed | Aligned |

| Keidanren (Japan Business Federation) | Aligned | Aligned | Aligned | Aligned |

The Japan Iron and Steel Federation

- Purpose:To promote the sound production, distribution, consumption, and trade of steel, thereby contributing to the development of the Japanese economy and the improvement of people’s livelihoods.

- Participation of JFE Group Officers:Vice Chairman, Masayuki Hirose, Representative Director, President and CEO of JFE Steel Corporation

| Item | Result | Basis / Reference URL, etc. |

|---|---|---|

| GX Policies | Aligned | In 2021, the Federation announced the Basic Policy of the Japan steel industry on 2050 Carbon Neutrality, in which it declared its agreement with the ambitious national policy of achieving carbon neutrality in 2050 and its own bold commitment to take on the challenge of realizing carbon neutrality in the steel industry. It has also requested the establishment of a national strategy for decarbonization, financial support to commercialize and implement the results of technology development, fostering public understanding that achieving decarbonization will involve significant costs, and building mechanisms for sharing such costs across society. |

| Energy Policy | Aligned | In its comments on the draft 7th Strategic Energy Plan, the federation recognized it as a realistic plan that squarely addresses changes in the energy situation while maintaining the S+3E perspective, and that reemphasizes the importance of stable supply and economic efficiency. It also valued the fact that resource-poor Japan will have a number of options, including renewable energy, nuclear power, and decarbonized thermal power, moving away from the conventional binary view of renewables versus nuclear. It has also stated that the integration of energy policy and industrial policy is an extremely important perspective in advancing GX, and that specific policies are needed to promote decarbonization on the premise of strengthening industrial competitiveness and ensuring inexpensive and stable energy supply. |

| Carbon Pricing | Aligned | In its comments on the draft GX2040 Vision, the Federation valued the Growth-oriented Carbon Pricing Concept for clearly indicating the timing of introduction and the basic framework of emission trading schemes and other systems. It stated that designing the GX-ETS system requires appropriately reflecting differences in timelines and marginal abatement costs for decarbonization by sector and designing a system that supports GX promotion in the Japanese steel industry while sustaining domestic production capacity and maintaining and strengthening international competitiveness. In addition to introducing carbon pricing, the federation has also underlined the urgency of creating a GX product market to ensure investment predictability for GX. |

| Creation of GX Product Markets | Aligned | The federation considers the creation of a GX market essential for increasing the predictability of decarbonization investments. In its comments on the draft GX2040 Vision, it valued the extensive descriptions regarding GX market creation, particularly the immediate implementation of initiatives such as visualization of GX value, public procurement, and private procurement. It has also expressed that the government’s proactive initiatives, including the creation of initial demand, are extremely important for GX market creation, that clear policy directions for steadily expanding market size are required, and that more concrete measures such as regulatory and institutional measures for procurement are necessary to enhance investment predictability and that the government should present a more specific roadmap. |

World Steel Association

- Purpose:To promote sustainability, safety, technological innovation, and human resource development in the steel industry and contribute to the overall development of the industry through international collaboration and the provision of information.

- Participation of JFE Group Officers:Member of the Executive Committee — Masayuki Hirose, Representative Director, President and CEO of JFE Steel Corporation

| Item | Result | Basis / Reference URL, etc. |

|---|---|---|

| GX Policies | Aligned | In its policy paper “Climate change and production of iron and steel ,” worldsteel expressed its full support for the goals of the Paris Agreement and declared that it would realize industrial and social transformation by reducing CO2 emissions from steel production. |

| Energy Policy | Aligned | The same policy paper recommended the utilization of low-carbon energy, such as renewable energy, nuclear power, and fossil fuels with mitigation technologies such as CCS as a technological option for the steel industry’s climate change measures. |

| Carbon Pricing | Position yet to be expressed | |

| Creation of GX Product Markets | Aligned | The policy paper also noted that steel products using low-carbon technologies will be more expensive than conventional products and therefore require policy support to compete in the market. It also pointed to rising demand from customer companies for low-carbon steel products. To meet this demand, worldsteel proposed a method for allocating GHG emission reduction value to specific products (chain of custody, or CoC) and published principles and guidelines to enhance transparency and clarity regarding the application of this method. |

Keidanren (Japan Business Federation)

- Purpose:To draw out the vitality of companies, individuals supporting companies, and local communities as a comprehensive economic organization, thereby contributing to the autonomous development of the Japanese economy and the improvement of people’s livelihoods.

- Participation of JFE Group Officers:Chairman of the Tax System Committee — Yoshihisa Kitano, Representative Director, President and CEO of JFE Holdings, Inc.

| Item | Result | Basis / Reference URL, etc. |

|---|---|---|

| GX Policies | Aligned | In its 2022 publication “Toward Green Transformation (GX) ,” Keidanren expressed the view that to realize carbon neutrality by 2050, Japan as a whole must create a “virtuous cycle of the economy and environment” and promote Green Transformation (GX), representing the transformation of the entire economic and social system. It also recommended that the government formulate a GX Policy Package as a grand design for GX. |

| Energy Policy | Aligned | In its 2024 proposal “Recommendations for Revising the Strategic Energy Plan ,” Keidanren stated that ensuring safety is the fundamental premise, and that the principles of (a) energy security and stable supply, (b) economic efficiency, and (c) environmental compatibility (S+3E) must be upheld. It emphasized the need to pursue an optimal mix of diverse energy sources suited to Japan’s characteristics, to further expand the introduction of renewable energy that meets the three requirements of low cost, stable supply, and business discipline, and to maximize the use of nuclear and atomic energy. |

| Carbon Pricing | Aligned | In its comments on the public consultation for the “Basic Policy for the Realization of GX,” Keidanren evaluated the government’s growth-oriented carbon pricing concept as a key step for achieving more than 150 trillion yen in public and private GX investment while reducing and curbing emissions. It also requested that, while fully considering technological developments and the opinions of the business community, specific system design should proceed in a way that contributes to maintaining and strengthening industrial competitiveness. |

| Creation of GX Product Markets | Aligned | In its comments on the public consultation for the GX2040 Vision (Draft), Keidanren stated that creating a GX market is indispensable for enhancing the predictability of GX investment. It proposed that, in addition to measures such as visualization of GX value and demand-stimulating initiatives, a specific roadmap should be formulated that specifies the timing of introducing various regulatory and institutional measures. It also emphasized that the cost increases associated with the production of GX products should be reliably reflected in product prices, and that consumers who purchase such products should accept these cost increases so that they can be fairly and equitably distributed across society as a whole. |