Providing Quality Products and Enhancing Customer Satisfaction

Basic Policy

Under its corporate philosophy of contributing to society with the world’s most innovative technology, the JFE Group will continue to be a company that provides world-class products and services for a prosperous global future.

JFE Group Standards of Business Conduct

-

Provide quality products and services

Earn the trust and acclaim of customers by endeavoring to provide safe, high-quality products and services based on superior technologies, and by fully respecting and protecting the privacy of personal and customer information. Also, leverage our superior technologies for the sustainable growth of our Group and society.

Targets and Results

Under its Standards of Business Conduct to provide quality products and services, the JFE Group has identified increasing efficiency and enhancing cost competitiveness in production and engineering and raising quality of products and services and ensuring reliable supply as two key management concerns and sets KPIs to manage progress and promote relevant initiatives.

Initiatives

JFE Group’s Quality Initiatives

The JFE Group manages quality by ensuring compliance with quality standards set by each operating company. All manufacturing sites that require ISO 9001 certification for their quality management have been duly certified.

Strengthening Quality Assurance System

ST Initiatives to Improve Product Quality

To serve customers by meeting their quality requirements and delivering products that boast the world’s highest quality, JFE Steel has established a quality assurance system with advanced sensors for process monitoring, in addition to its ongoing efforts to develop new products and advanced manufacturing technologies.

We are conducting activities across the company in line with the Guidelines for Enhancing Quality Assurance Systems formulated by the Japan Iron and Steel Federation (JISF) to strengthen our quality assurance system. In addition to conducting product tests using high-precision testing and inspection equipment, we are striving to thoroughly prevent errors in identification tasks and data tampering by promoting automation in every process, from issuing test instructions and collating specimens to reporting results.

Moreover, the company intends to provide customers with innovative value by operating its quality management system based on ISO 9001 and by advancing the acquisition of various assurance certifications required for steel products, including the JIS mark and approvals from ship classification bodies. We are also actively promoting the formation and standardization of international rules in conjunction with future DX promotion and the social implementation of technologies obtained through research and development.

ST Initiatives to Supply High-Quality Products

JFE Steel is working to improve its manufacturing capabilities by actively utilizing digital technologies in its manufacturing processes.

While strengthening its manufacturing base by introducing a cyber-physical system (CPS) for all manufacturing processes, JFE Steel is also striving to improve quality and yield through the full-scale introduction of quality prediction technology that uses integrated data from steelmaking to final processing, and to enhance reliability by increasing the frequency of automated testing and inspections. These activities will stabilize facility operations as well as production and quality to safeguard the consistent delivery of high-quality products to customers.

EN Promoting Quality Activities Based on the Companywide Quality Policy

JFE Engineering has established a companywide quality policy stating that “products and services that JFE Engineering designs, procures, manufactures, or constructs must comply with all required rules, regulations, and standards, and quality must satisfy the needs of our customers” and that we will continually undertake improvements. Under this corporate policy, the company continually strives to improve the quality of its products and services.

Specifically, our certified inspectors conduct on-site inspections at each phase of a plant construction project, including procurement, manufacturing, construction, and pilot operations. We also conduct witness inspections by customers during critical processes and at the time of equipment delivery to ensure quality.

In addition, JFE Engineering has published quality-assurance manuals based on the specific characteristics of each product and obtained ISO 9001 certification for each product category.

To further strengthen its quality assurance system, JFE Engineering uses an electronic document processing system in its quality inspections to prevent omissions in inspection data and data tampering, and all inspection data is electronically stored to further ensure traceability.

EN Securing Construction Business Operators

JFE Engineering have been designated as a special construction business operator under the Construction Business Act to undertake mechanical, civil engineering, and building construction work, and assign dedicated managing engineers at construction sites to oversee the technical aspects of construction work. The smooth implementation of plant construction projects depends on licensed specialists. The company is always striving to secure the necessary human resources by encouraging employees to acquire qualifications by granting allowances and through mid-career hiring of licensed personnel.

SH Maintaining and Improving Quality Assurance Level Based on Quality Philosophy

Guided by its quality philosophy of continuing to provide products that satisfy the required quality to ensure that we are always trusted by our customers, JFE Shoji is constantly striving to enhance the level of its quality assurance for customer confidence and satisfaction. Its processing centers in Japan and abroad are systematizing and automating operations to eliminate human errors. Raising employee awareness is essential for preventing human error at every stage, from receiving orders to processing, inspecting and shipping. The company provides quality education for employees by introducing case studies of nonconformance at other companies as well as at Group companies in Japan and abroad. Moreover, we conduct periodic quality audits at all relevant Group companies in and outside of Japan to identify quality assurance risks, and we provide follow-up toward improvement. When follow-up is necessary, individual responses are carried out to maintain and enhance the level of quality assurance.

Proper Export Procedures

Each JFE operating company promotes international peace and security by working against the spread of weapons of mass destruction and excess accumulation of conventional weapons. Specifically, the company carries out internal inspections to confirm the final destinations, customers and applications of its exported products, and then ensures that export procedures are carried out properly. In addition, the Legal Affairs Department conducts internal briefings to disseminate knowledge of export-related laws and regulations, such as the Foreign Exchange and Foreign Trade Act. Also, education on export security controls and related measures is implemented for the employees of Group companies involved in trading.

Improving Customer Satisfaction

ST Aggressive Advancement of DX

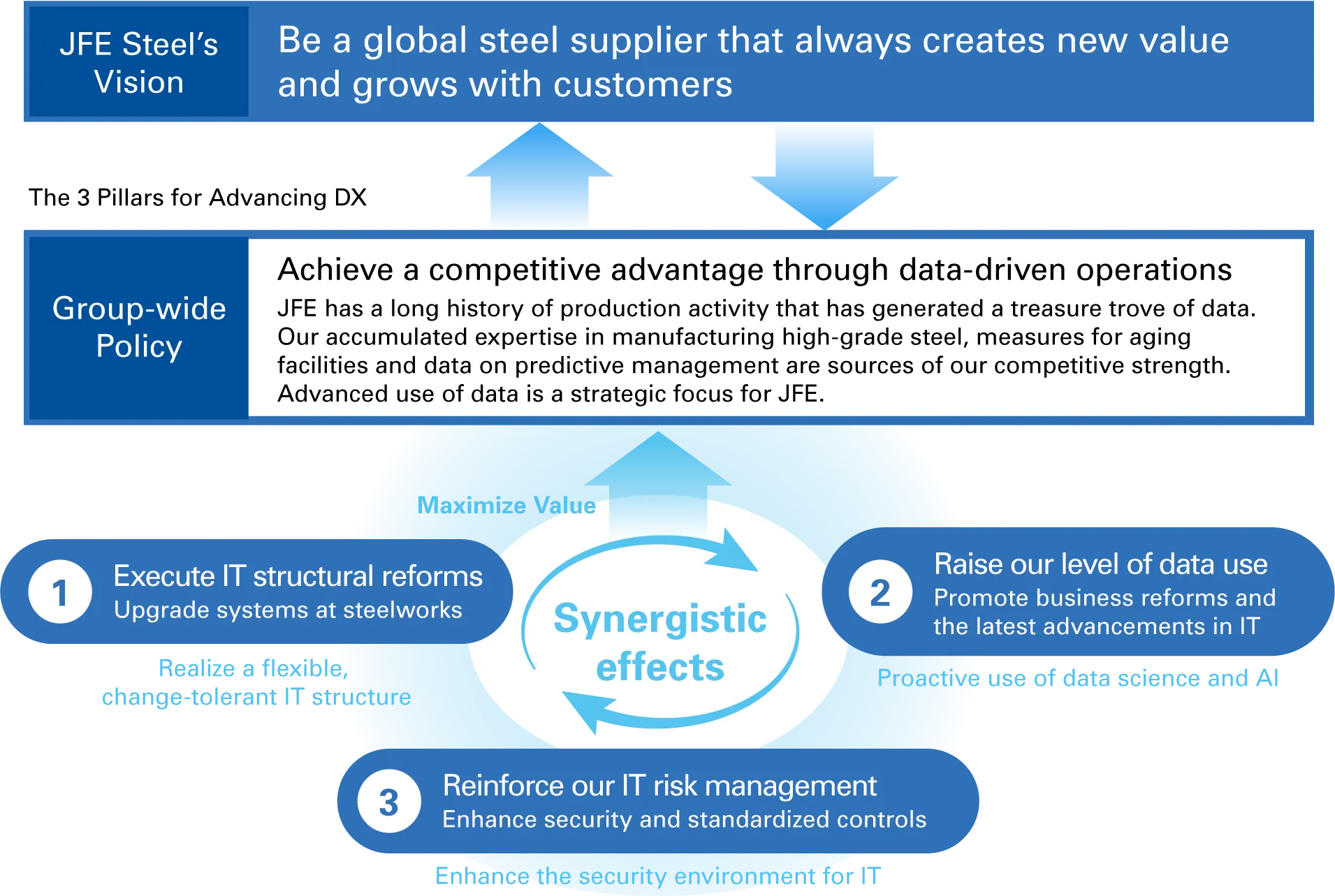

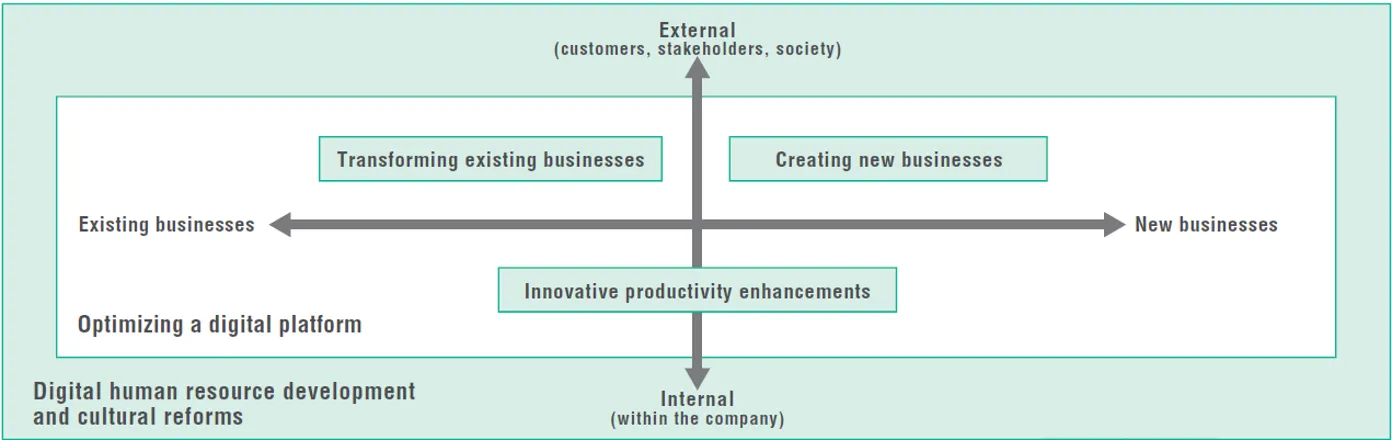

JFE Steel’s Digital Transformation (DX) strategy revolves around technological innovation based on the active introduction of IoT, AI and data science (DS) and the application of data assets. Compared to mills in other countries, we possess an enormous amount of know-how and data accumulated through many years of production operations. Our abundant data assets are the source of our value creation.

We will harness the latest DS and AI technologies to make versatile use of such data in achieving innovative improvements in productivity, enhancing quality, and ensuring stable operations to improve customer satisfaction.

Advancement of Digital Transformation (DX)

For more information on our DX, please refer to:

ST Testing and Research Centers for Collaboration with Customers on Product Development

JFE Steel collaborates with customers in research and development. The Customers’ Solutions Lab (CSL) for auto industry customers and the JFE Welding Institute-Center for Integrity against Fatigue and Fracture (JWI-CIF2) are located in eastern Japan, while the Customer Center Fukuyama (CCF), which develops materials and conducts applied technology research, is in western Japan. Using these facilities to strengthen early vendor involvement (EVI)* enables the company to quickly identify customer needs and develop products based on cutting-edge evaluation techniques and innovative production processes.

- *Customer participation in product development is from an early stage to facilitate innovative new methods, functions, processes and evaluations for new steel materials.

ST Enhancing Our Response to Customer Needs

In an effort to strengthen the company’s total capabilities for better responding to customer needs, its sales department emphasizes enhanced sales education for sales personnel by position at the headquarters and branch offices. Specifically, we develop abilities in areas such as engaging in technical conversations, picking up clues from customer relations and using them in product development, offering suggestions to improve logistics and distribution, and analyzing financial indicators and costs. We also constantly strive to improve our systems so that customer product specifications are accurately reflected in manufacturing, and we will continue to work on improvements.

ST Unified Customer Care

JFE Steel regularly conducts customer questionnaires and interviews to draft strategies for greater customer satisfaction. Business strategies are shared among the sales divisions, the business planning functions and steelworks to facilitate unified customer care and proposals that leverage the collective strengths of the JFE Group

EN Create and Continue to care for the Foundation of Life by Maximizing DX

JFE Engineering plans, designs, builds and operates the infrastructure that supports people’s lives and industry. Digital transformation (DX) is crucial for accelerating the pace of its work and for maintaining its position at the forefront of the engineering industry. JFE Engineering will aggressively pursue DX beyond simply raising operational efficiency to fundamentally reform its operational processes, add new functions to its products and services, and take on the challenge of developing new businesses that utilize data, to realize a green society and enhance corporate value.

JFE Engineering’s DX strategy

For more information on our DX, please refer to:

EN Company Assessments Based on Customer Evaluations

JFE Engineering uses customer surveys, interviews, and contractor performance evaluation forms to collect and assess data on the company’s construction management, quality, advanced technologies and innovation. Each division analyzes and applies the data for quality improvement, new product development and the overall strengthening of aftersales service, to ultimately enhance customer satisfaction.

SH Establishing a System to Meet Customer Needs

To respond to diversifying markets and increasingly advanced customer requirements, JFE Shoji is promoting DX solutions that take advantage of the strengths of the JFE Shoji Group. Placing “Safety” as a central theme, JFE Shoji Electronics Corporation, a JFE Shoji Group company, has begun offering a Safety AI System and Safety AI cameras designed for installation on heavy machinery.

These cameras help supervisors detect when workers enter hazardous areas or come close to moving machine components and enable effective monitoring of on-site work activities. In addition, JFE Shoji Electronics provides secure network cameras as well as smartphone-type cameras, which support operational improvements such as reducing the need for physical patrols and facilitating efficient root-cause analysis using recorded video footage.

Overview of the Safety AI System

- Enables the pre-designation of dangerous areas, triggers alarm via a signal light, and automatically stops equipment operation

- In conjunction with the optional VMS*, supports video recording, reviewing, and analysis

For more information on our DX, please refer to:

Promotion of Research and Development

ST Promoting Technological Development to Meet the Needs of Customers and Society at Large

JFE Steel is advancing research and development of innovative technologies in the steelmaking process to contribute to achieving carbon neutrality by 2050. These include CO2 reduction technology, carbon-recycling blast furnaces with CCU, and hydrogen-based ironmaking (direct reduction). The company is also actively applying data science and robotics to drive technological development that meets the evolving needs of customers and society at large.

In addition, JFE Steel is accelerating the introduction of new products and solutions for each field, with automobiles including EVs and new energy as key areas of R&D.

EN Promoting Research and Development Based on the Long-Term Vision

Guided by its long-term vision, JFE Engineering is prioritizing research and development in two key areas: green transformation (GX) for carbon neutrality and digital transformation (DX) for business sophistication and efficiency. In GX, the company conducts R&D to achieve its FY2035 target of reducing 30 million tonnes of CO2 emissions. Key initiatives include developing manufacturing technologies for monopile foundations for offshore wind power generation, low-energy CO2 separation and capture technology that uses a hybrid of membrane separation and physical adsorption methods, and waste-to-chemical technologies that convert waste into chemical raw materials.

Internal Awards

The following technical and product developments were awarded in FY2024.

Internal Awards (FY2024)

| Prize/Award | Project | Recipient | |

|---|---|---|---|

| JFE Steel | Grand Prize/Excellence Award, JFE Steel President’s Awards | Establishing a low-cost, high-productivity hot-rolling system at the Fukuyama District by developing the J-Lecoa™ hot-rolled coil stabilization DS technology | Hot Rolling Department, West Japan Works (Fukuyama District) |

| Establishing an environmentally harmonized formed coke production technology through advanced technological development—effective use of low-grade resources by expanding formed coke technology | Coke Technology Department | ||

| Significant improvement in freight rate competitiveness for long-distance transport through optimized transportation conditions and methods | Logistics Planning Department | ||

| Establishment of a high-profit product manufacturing system at the Chiba Hot Strip Mill in the short term | Hot Rolling Department, East Japan Works (Chiba Works) | ||

| Establishment of a stable supply system for hot-dip galvanized steel sheets for automobiles under high operation levels | Process Control Department, West Japan Works | ||

| Establishment of a production system for strict-surface-hardness sour-resistant steel | Plate Department, West Japan Works (Fukuyama District) | ||

| JFE Engineering | Grand Prize, JFE Engineering President’s Awards | Ultimate teamwork between humans and robots: next-generation technology that revolutionizes bolt tightening | Social Infrastructure Headquarters |

For more on the external awards, please refer to: