Occupational Health and Safety

Initiatives

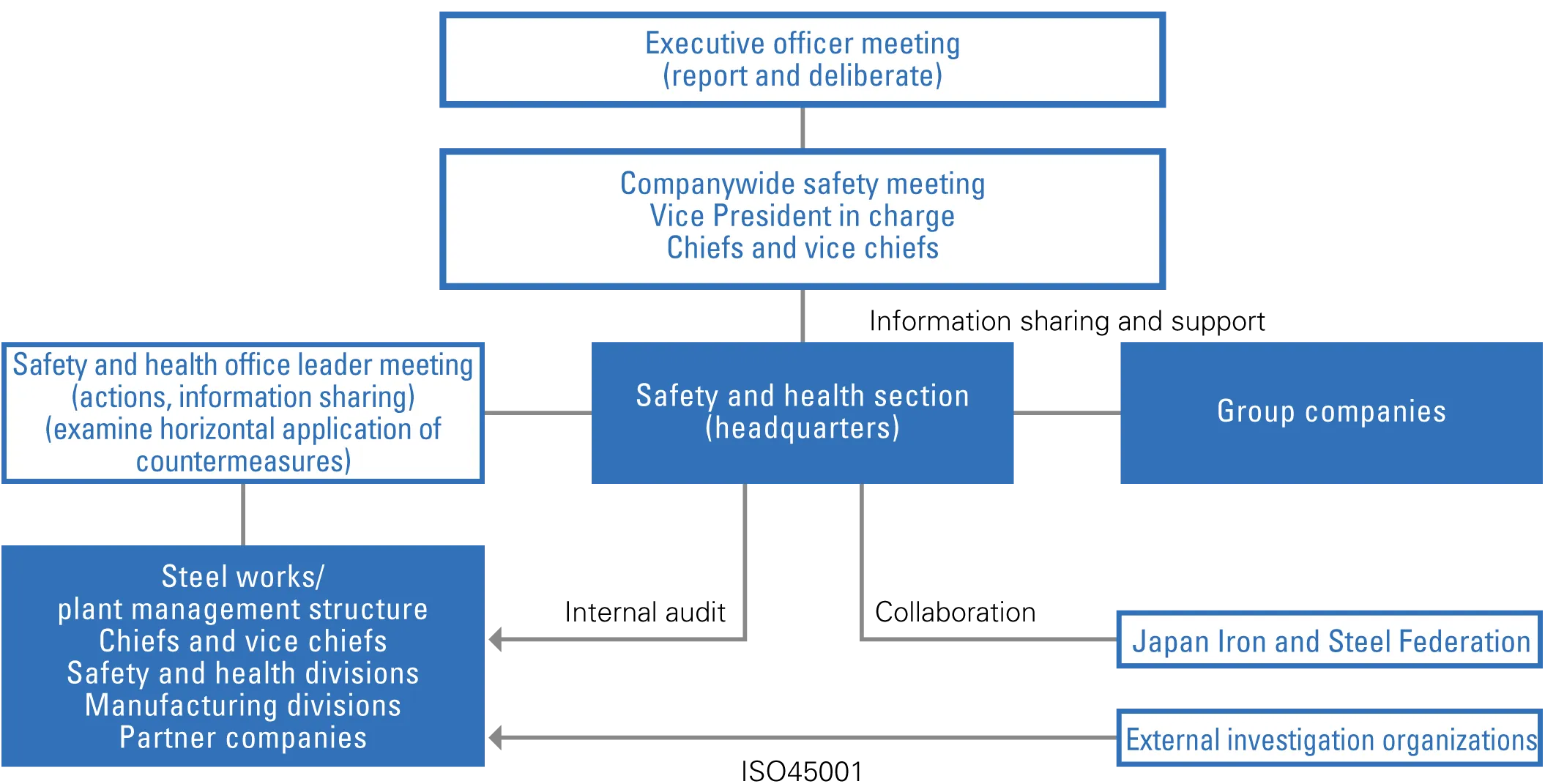

To ensure safety at its operating companies, the JFE Group regularly reports to the Board of Directors, which provides direction and supervision. It also holds discussions on health and safety with the labor unions through the Occupational Health and Safety Committee.

Under the Eighth Medium-term Business Plan, we are working to establish workplace conditions in which everyone at Group and partner companies (including contractors) can work safely. In addition to instilling a strong personal and organizational awareness of safety, the operating companies will continue investing in safety at the same scale as the Seventh Medium-term Business Plan (approximately 10 billion yen per year), advancing the complete separation of moving equipment and personnel through facility modifications, and further promoting multifaceted health and safety management, such as monitoring and detection, using DX.

The JFE Group organizes training programs for newly appointed managers and supervisors to provide information on the Industrial Safety and Health Act and risk assessment regulations and on formulating work plans and policies for health and safety management. In the construction department, we offer programs for local superintendents in charge of construction work (Overall Safety and Health Controller) centered on the Industrial Safety and Health Act as well as related regulations for subcontractors and the Construction Business Act (369 participants in 2024). We also conduct new employee training and position-specific training on mental health (1,367 participants in 2024).

For data related to lost-work injuries at each company, please refer to:

ST Occupational Health and Safety Initiatives Based on Two Strategies

This is the Group’s health and safety activity policy in 2025: On the safety front, we are promoting independent, self-directed safety activities to ensure regulatory compliance and create accident-free workplaces. On the health front, we are promoting activities based on the Health Declaration to increase the number of employees who can work in good physical and mental health over the long term. In accordance with our goal of achieving zero accidents Groupwide and zero accidents at each workplace, we are implementing the following activities.

For safety, we are striving to establish safety-conscious employees and workplaces by promoting regulatory compliance, conducting activities to prevent recurrence of similar accidents, and engaging in open dialogue with frontline workers to identify and address risks. To create accident-free workplaces, we are also striving to ensure the intrinsic safety of equipment and operations by proactively budgeting to improve workplace issues (safety investments), introducing machinery safety standards, and applying DX technologies, thereby reducing the level of worker risks.

For health, we are pursuing health initiatives based on the Steel Health and Productivity Management Strategy Tree, developed in response to the JFE Group’s Health Declaration.

In order to more independently and systematically promote occupational health and safety management throughout the organization, we established an occupational health and safety management system in accordance with the ISO 45001 international standard and obtained ISO 45001 certification (JIS Q 45001) for all our construction and operating sites. We will continue making workplaces safer and healthier through an ongoing and effective operation of the occupational health and safety management system.

Management Structure for Health and Safety

Certified Sites

- Chita Works (certified on September 9, 2021 ⇒ renewed on September 9, 2024)

- Fukuyama Area (certified on December 16, 2021 ⇒ renewed on December 16, 2024)

- Kurashiki Area (certified on May 26, 2022 ⇒ renewed on May 26, 2025)

- Chiba Area (certified on May 26, 2022 ⇒ renewed on May 26, 2025)

- Sendai Works (certified on December 15, 2022 ⇒ will be renewed in 2025)

- Keihin Area (certified on January 19, 2023 ⇒ will be renewed in 2026)

In the event of an industrial accident, the department in which the incident occurred investigates the cause and formulates and implements actions to prevent recurrence. At the same time, we inform the relevant departments and labor union through the Occupational Safety and Health Committee. We will also set up a disaster investigation committee as necessary and forward recommendations to the department where the accident occurred as well as related departments so that they can develop appropriate measures to prevent recurrence. In the event of severe accidents, a response is deployed across the company, and a standard progress report is submitted to Corporate Officer Council until countermeasures have been completed. In the event of other incidents and near-misses, the health and safety departments discuss and determine the need to deploy a companywide response and follow up on progress until the companywide deployment is completed. This practice has been standardized across the entire company.

We immediately report industrial accidents to the Japan Iron and Steel Federation (JISF) under the required guidelines. We file an update once we have determined the cause and decide on countermeasures. In the event of severe accidents, we promptly submit a report on safety, disaster prevention and environmental issues to the Ministry of Economy, Trade and Industry, the Ministry of Health, Labor and Welfare, and the JISF.

EN Ensuring Employee Health and Improving Occupational Health Level

Management Structure for Health and Safety

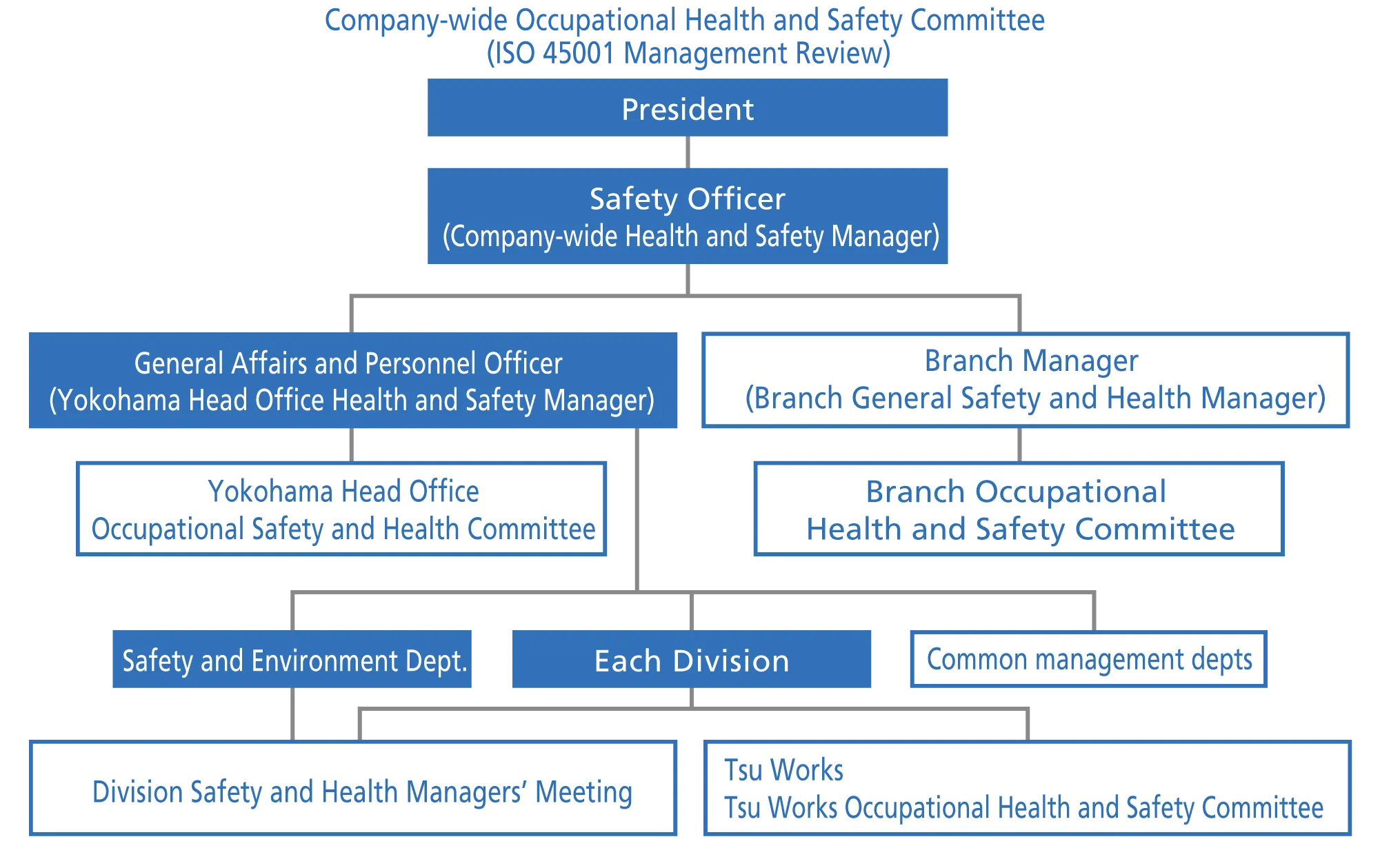

In addition to setting up governance organizations for health and safety at each operating site to comply with the Industrial Safety and Health Act and in line with the type of work and number of employees, JFE Engineering has established a governance structure for health and safety at each operational headquarters to facilitate and effectively implement companywide management at its construction and operating sites and manufacturing plants. JFE Engineering strives to eliminate disasters at all suppliers and Group companies by establishing priority items to be shared across the company and to which all employees and all staff at suppliers adhere. It also endeavors to identify sources of danger as well as safety measures through risk assessments aligned with the particular characteristics of each individual operational headquarters. Meanwhile, it promotes physical and mental health and the creation of comfortable working environments as a means of ensuring the health of employees and bringing occupational health to an overall higher level.

In the event that an industrial accident occurs, occupational health and safety managers will meet to determine the cause and consider countermeasures that will be deployed across the company. Since 2016, the company has been operating an occupational health and safety management system (ISO 45001 certified) for its construction activities in Japan and overseas as well as its manufacturing operations at the Tsu Works. As a new initiative, JFE Engineering applies IT solutions promoting occupational health and safety, including monitoring and detection by multiple approaches.

SH Enhanced Health and Safety Activities and Establishing a Safe and Secure Working Environment

JFE Shoji is implementing the following activities to eliminate unsafe operations that could lead to severe accidents for achieving zero severe accidents at its coil centers and other processing sites.

- Risk assessment by supervisors patrolling the site and identifying unsafe operations using the recording functions of safety cameras, or by ensuring that each worker is engaged in hazard prediction

- Comparative study of similar disaster cases and hazard experience training for improving the ability to recognize and avoid unsafe operations

- Facility improvement for reducing risks, including installation of safety sensors

- Operation training (slinging for cranes and other skills) and review of operational standards

Furthermore, for each of its Group companies, JFE Shoji assigns a safety manager to spearhead these efforts to raise the level of health and safety activities. To ensure that all JFE Shoji Group companies operate under the same values, safety managers meet every other month to share knowledge and information on occupational health and safety

Annual safety awards are also presented to encourage employees to actively engage in health and safety activities. Through these initiatives, the company will raise the level of safety management within the JFE Shoji Group and continue to maintain safe working environments.

Intrinsic Safety through DX

ST Designing Lines that Protect Even in the Event of Human Error

As part of our safety objectives in 2025 to create accident-free workplaces, we are promoting the use of DX technologies to ensure safety even when someone mistakenly enters a hazardous area. For example, we have introduced person-detection systems where it is impractical to install physical barriers separating internal production line operations from external areas, creating a risk of inadvertently venturing into danger zones. These systems detect someone entering into a hazardous area and can prevent accidents by either immediately interrupting equipment operation or preventing idle equipment from starting. Another example is the introduction of a safety monitoring system that links smartphones with portable gas monitors to detect concentrations of oxygen, carbon monoxide, combustible gases, and hydrogen sulfide, and determine the safety and suitability of working under those conditions. We also use smartphone GPS functions to detect the positions of heavy machinery and other equipment to further safeguard worksite safety. This information is immediately communicated to workers, and recorded location data is used in facility improvements.

Going forward, we will continue introducing DX technologies.

EN Intrinsic Safety at Construction Sites through DX

JFE Engineering is implementing innovative efforts that leverage digital technologies to fundamentally enhance construction site safety.

Three-dimensional simulation technology is used during construction planning to visualize the movements of cranes and structures in advance in order to identify and prevent potential interference risks with high-voltage power lines and surrounding structures before work begins. The technology also optimizes the placement of heavy machinery and material storage areas, as well as worker traffic flow, allowing everyone involved in the project to share a clear overview of the construction process and significantly reducing unnecessary work and errors.

The introduction of inspection robots and drones equipped with 3D measurement technology allows inspections of elevated structures such as viaducts and dimensional surveys of silos that previously required working at height to be performed safely from the ground or other secure locations.

This strategic use of digital technologies not only enhances worksite safety but also leads directly to greater efficiency and reduced costs, thereby contributing to sustainable growth in corporate value.

Health and Productivity Management

Companywide Targets for Each Operating Company

We collaborate with the health insurance association and occupational health staff to maintain and improve employee health. Under the Eighth Medium-term Business Plan, we have set a top-level goal of increasing the number of employees who are physically and mentally healthy and able to perform at a high level, thereby reducing presenteeism. To this end, we are systematically implementing improvement initiatives, such as support for early detection and continued medical treatment as well as smoking cessation and sleep improvement programs.

Presenteeism Performance Results

| Category | FY2024 Results | FY2025 Target | |

|---|---|---|---|

| JFE Steel | Percentage of employees who are physically and mentally healthy and working at 80% or higher performance (percentage of employees with presenteeism of 20% or less*)

|

66.3% | 67% |

| JFE Engineering | 64.1% | ||

| JFE Shoji | 74.6% |

Specific Operating Company Targets

| Category | Item | FY2024 Results | FY2025 Target | |

|---|---|---|---|---|

| JFE Steel | Support for early detection and continued treatment | Regular health checkup attendance rate | 99.9% | 100% |

| Dependent spouse health checkup attendance rate | 57.7%1 | 60% | ||

| Support for maintaining appropriate body weight | Specific health guidance implementation rate | -*2 | 60% or higher | |

| Obesity rate (BMI 25 or higher) | 31.1% | 30% or lower | ||

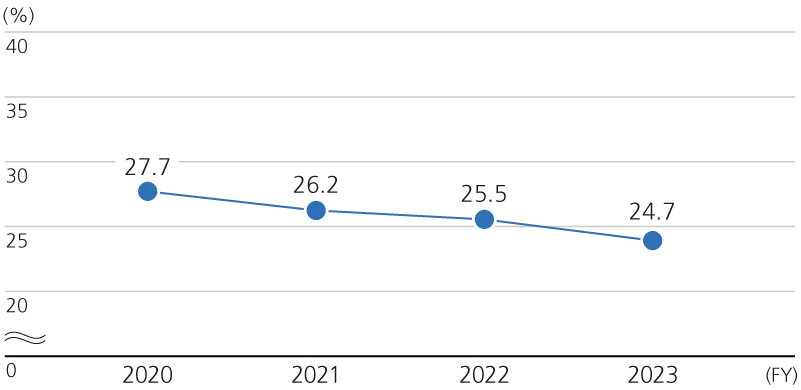

| Promotion of smoking cessation support | Smoking rate | 25.0% | Annual reduction of 1.5% | |

| Stress check | Stress check implementation rate | 98.0% | 98.0% or higher | |

| JFE Engineering | Sleep measures | Sleep risk (based on responses in health checkup questionnaire) | 42.9% | 35% or lower |

| Passive smoking remediation | Smoking rate | 21.4% | 20.9% or lower | |

| Obesity remediation | Obesity rate (BMI 25 or higher, or waist circumference ≥85 cm for men, ≥90 cm for women) | 42.4% | 38.3% or lower | |

| JFE Shoji | Support for early detection and continued treatment | Regular health checkup attendance rate | 100% | 100% |

| Re-examination attendance rate | 56% | 60% | ||

| Sleep measures | Sleep risk (based on responses in health checkup questionnaire) | 42.10% | 35.0% |

- *1Preliminary figure

- *2The result for the specific health guidance implementation rate will be added once confirmed.

- Note: At JFE Steel, the attendance rate for regular health checkups and the obesity and smoking rates are managed on a calendar-year basis.

Physical Health Initiatives

Changes in Smoking Rates (All Operating Companies)

- Ensure the implementation of regular physical examinations and strengthen cancer screenings.

- Prevent aggravation of lifestyle diseases by conducting metabolic syndrome checkups and offering health guidance.

- Utilize the health insurance union’s health promotion app, PepUp, to educate employees on physical exercise and other healthy habits.

- Promote non-smoking areas and maintain separate areas for smokers and non-smokers in buildings. Provide guidance to help employees quit smoking through industrial physicians and public health nurses.

Mental Healthcare

The JFE Group conducts four basic initiatives to maintain the mental health of employees: “self-care” for workers who strive to remain aware of stress and take preventive measures; “care by management supervisors” who provide advice to subordinates; “care by industrial health staff” who support employees, managers and supervisors; and “care by human resources outside workplaces,” including specialist clinics and individuals.

JFE’s health insurance union also provides mental health counseling, including a 24-hour hotline for employees and their families (spouse and dependents).

Initiatives on Health Issues

We operate a health management system for continuously and effectively managing the health of all employees, including those on overseas assignments and business trips and those studying abroad.

We particularly seek to ensure that employees working abroad, under healthcare systems that differ from those in Japan, can maintain a healthy lifestyle, along with their accompanying family members, by conducting health checkups and vaccinations before they move overseas, in accordance with Companywide regulations. In a proactive effort to prevent infections, we also provide information on global health issues such as COVID-19, HIV, tuberculosis, and malaria during assignment briefings. We will continue to monitor and appropriately respond to global health issues.

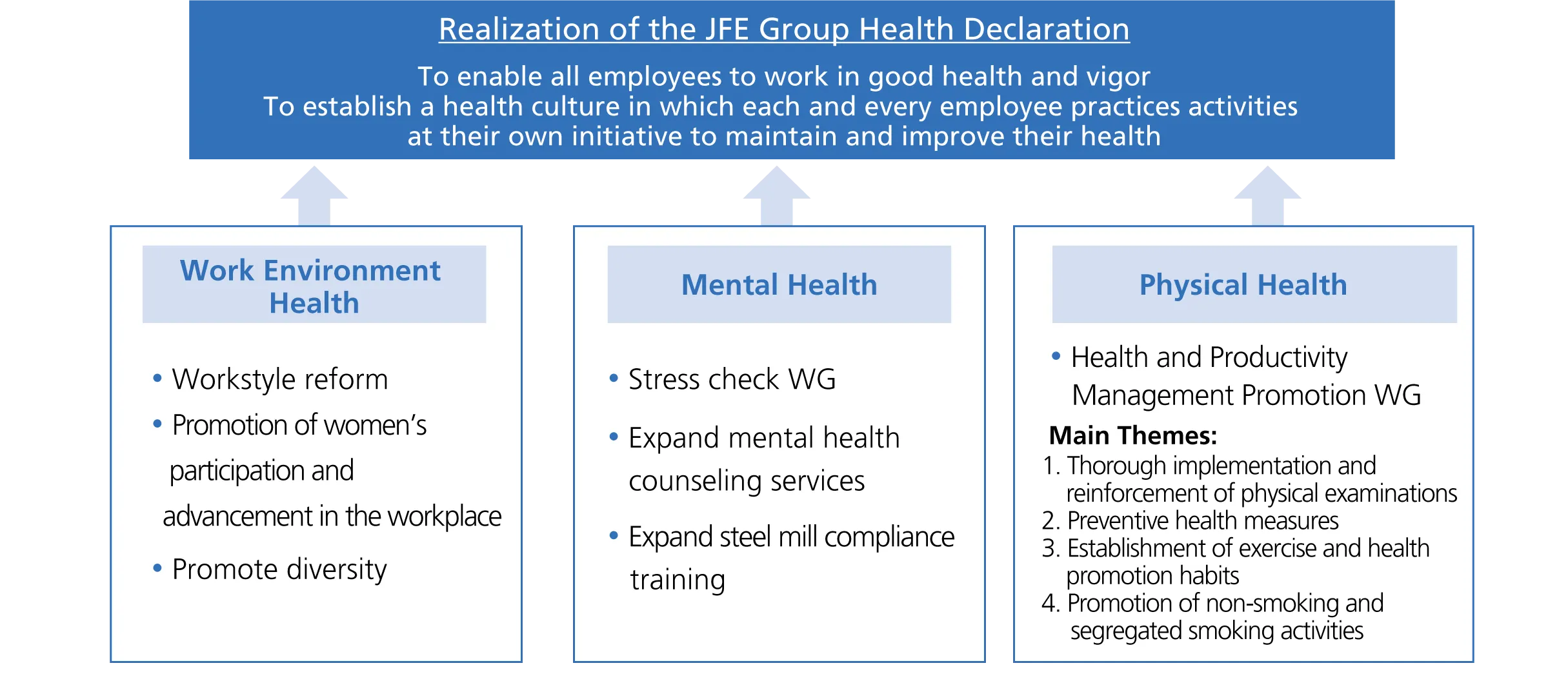

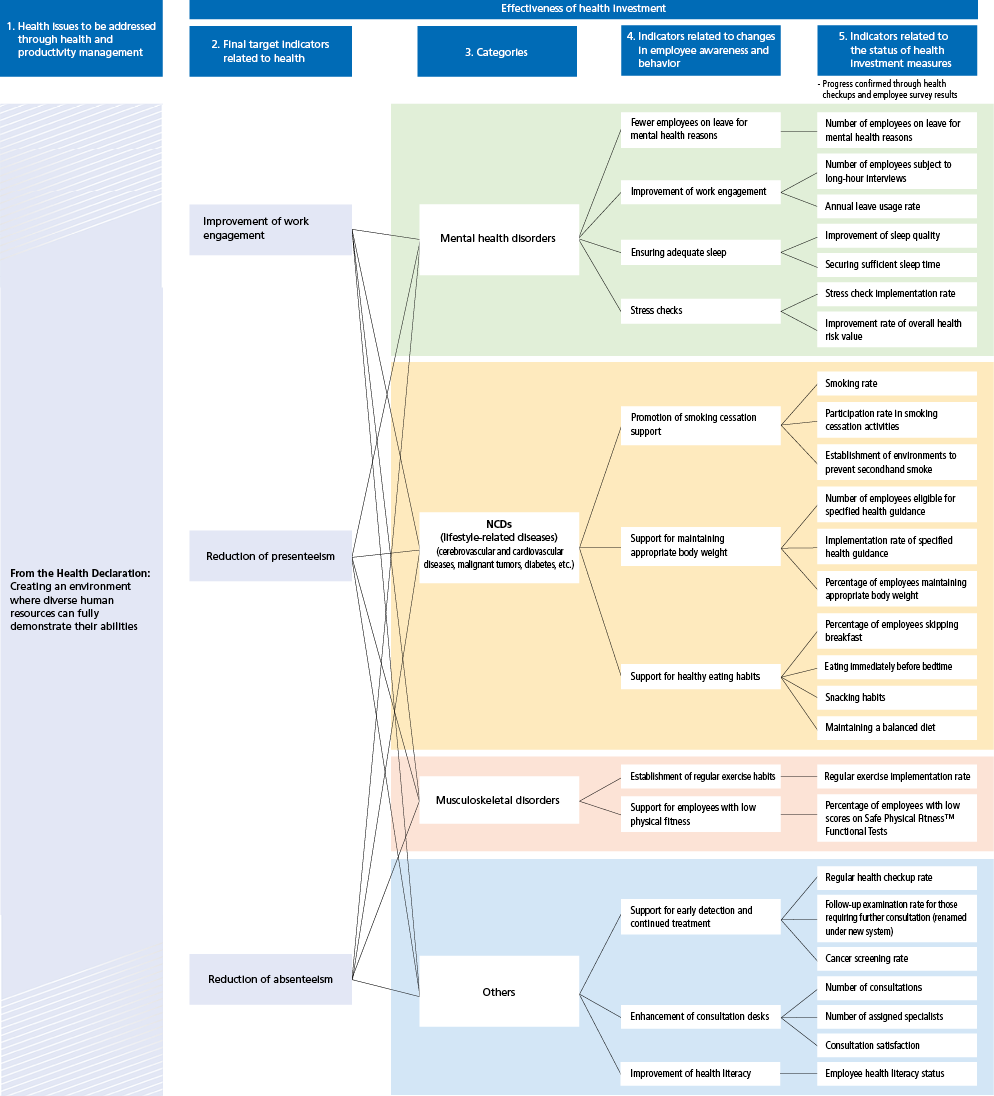

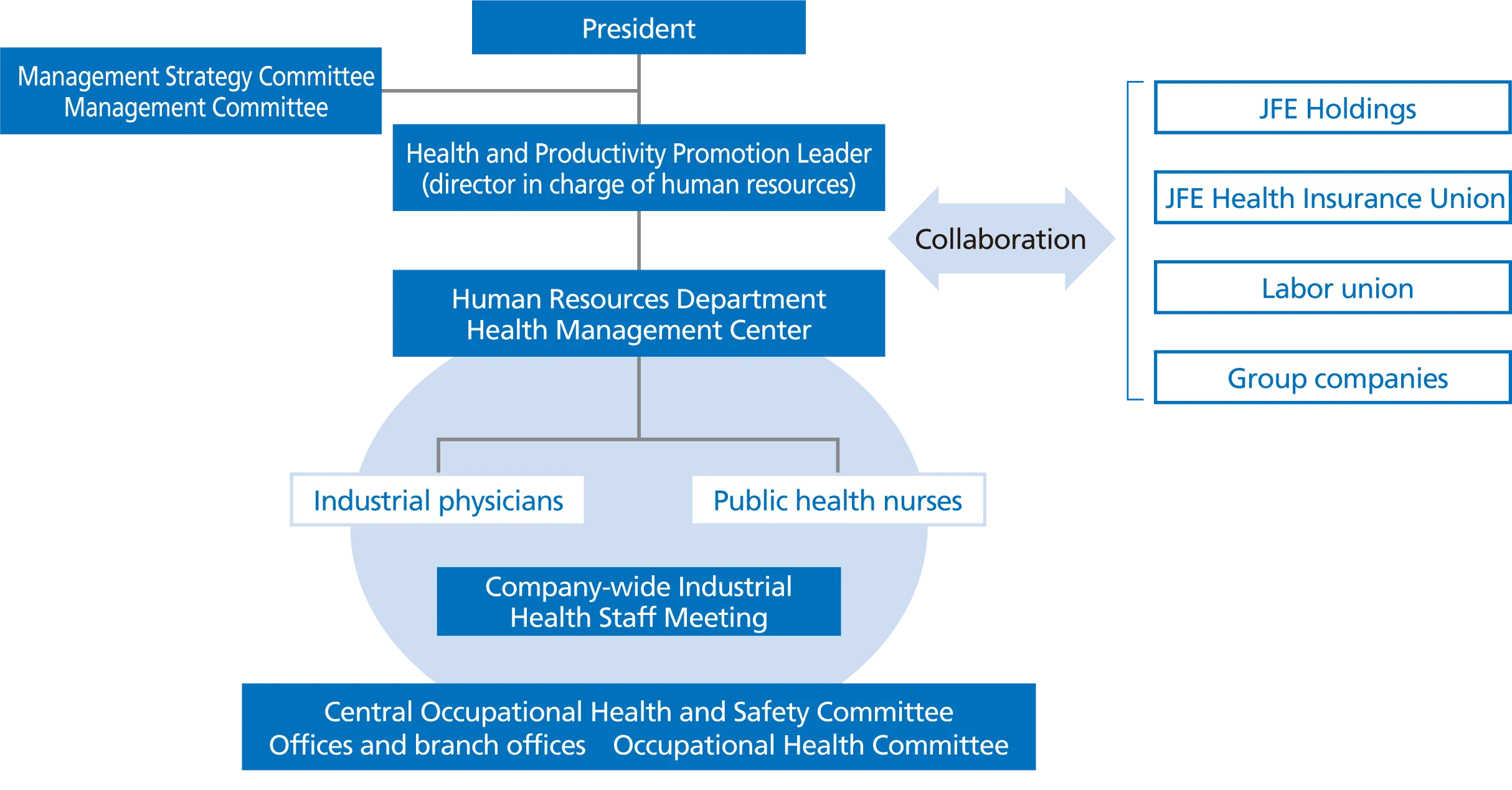

ST Promoting Health and Productivity Management to Maintain and Improve Health

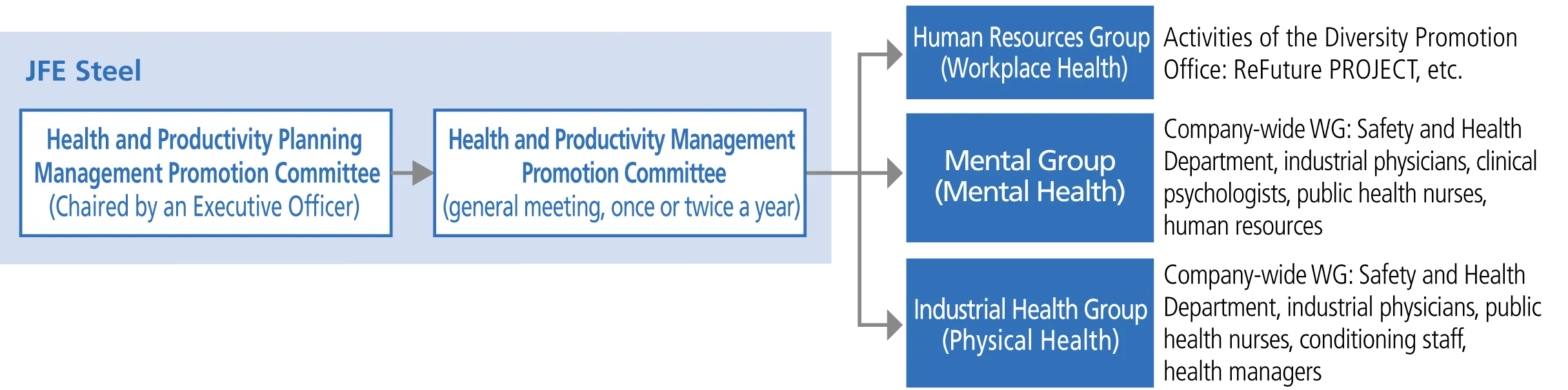

To maintain and improve the health of employees and their families, the JFE Group established the Group Health Declaration in 2016. In line with the declaration, JFE Steel launched the Health and Productivity Management Promotion WG and has been setting medium- to long-term companywide goals. We hope these activities will enable all employees to work healthily and vigorously, and we plan to establish a health culture in which every employee practices activities on their own initiative to maintain and improve their health.

In 2016, JFE Steel first focused on physical health and established key initiatives regarding: (1) thorough implementation and reinforcement of physical examinations, (2) preventive health measures, (3) establishment of sound exercise and health habits, and (4) non-smoking and segregated smoking activities. In 2024, the company expanded the scope to include mental health, and it has been promoting health and productivity management at all of its operating sites.

In 2025, it set a top-level goal of increasing the number of employees who can work in good physical and mental health over the long term. To this end, we created a Health and Productivity Management Strategy Tree that organizes specific actions for attaining this goal and are promoting health management across all of our operating sites.

Structure of Health and Productivity Management Promotion WG

Objective of the Health and Productivity Management Promotion WG

Health and Productivity Management Strategy Tree

ST Active Exercise® Health

JFE Steel business sites offer the Active Exercise™ program, designed by West Japan Works to help people increase their physical strength and prevent injuries from falling. The program’s effectiveness in preventing occupational accidents and improving health has even attracted attention outside the company, and through participation in the Ministry of Health, Labor and Welfare’s SAFE Consortium, initiatives such as Active Exercise™ and Safe Physical Fitness™ Functional Tests are being promoted not only among on-site partner companies but also among businesses in other industries.

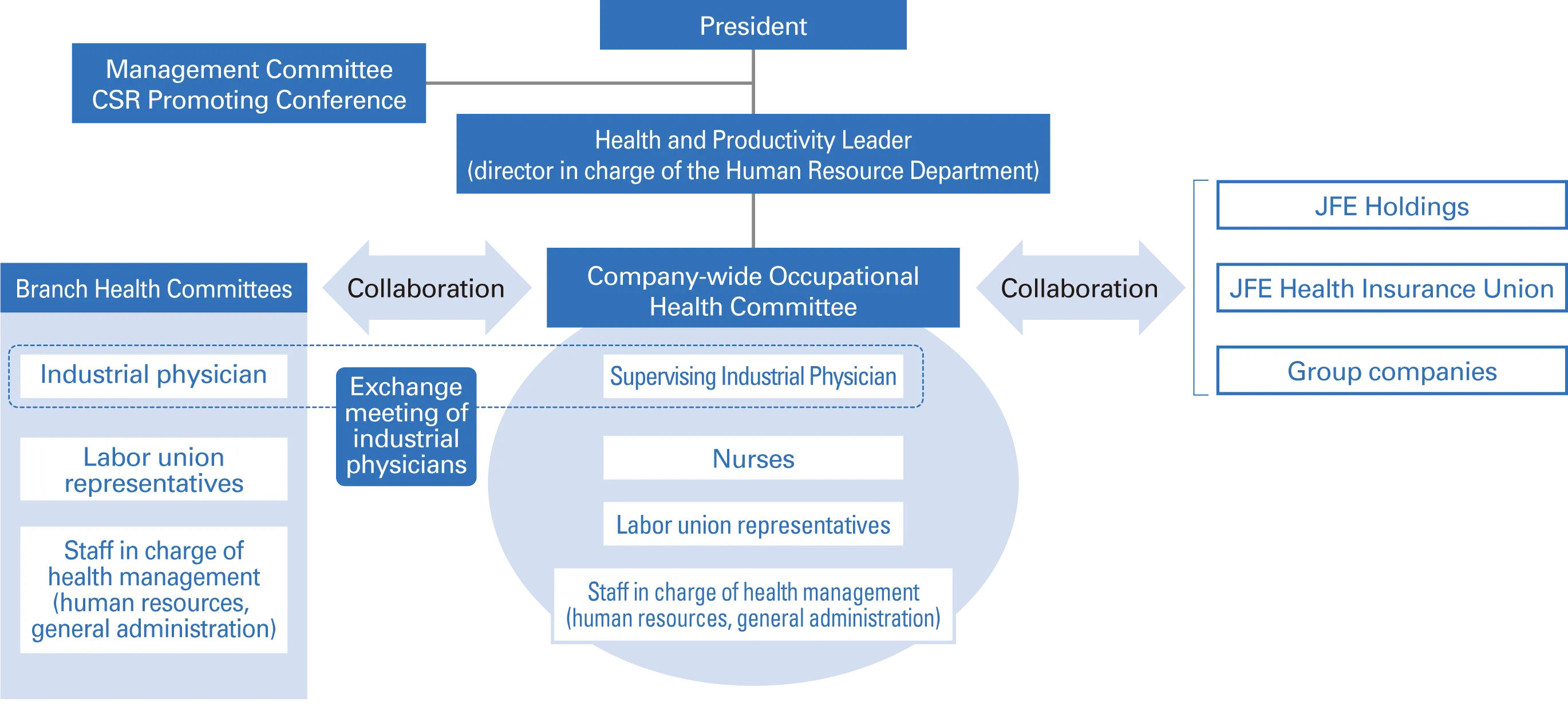

EN Engineering Activities for Boosting Health Based on Health Checkup Data

JFE Engineering maintains a system centered on the Health Management Center of the Human Resources Department, under which industrial health staff at each office and branch office cooperate to promote activities. The company is pursuing initiatives for improving health focused on five domains, including sleep, smoking and obesity issues extracted from past health checkup data, along with cancer and mental health. Every year, the Health Management Center compiles basic health checkup data and prepares the Data Book, which shows changes over time at a glance for the entire Company and major business sites. The center follows the PDCA cycle while reviewing the results of its initiatives.

In FY2024, JFE Engineering established the JFE Wellness Action 5, a set of five clear and practical health behavior guidelines designed to be easily understood and implemented by employees.

Health and Productivity Management Promotion System

Initiatives Based on Past Health Checkup Data

| Fiscal Year Launched | Purpose | Initiatives |

|---|---|---|

| 2018 | Preventing cancer | Stomach endoscopy during regular health checkups |

| 2019 | Improving sleep habits | Companywide self-care seminars to practice napping and breathing exercises |

| 2020 | Addressing obesity | Labor and management co-sponsored RIZAP seminars and workplace exercises at home |

| 2021 | Ending exposure to passive smoking | Complete ban on indoor smoking |

| Improving sleep habits | Companywide rollout of Self-care Seminar II focused on sleep-wake rhythms | |

| 2022 | Providing more personalized guidance | Provision of more individualized guidance on sleep, obesity, smoking, etc. |

| 2023 | Preventing cancer | Colonoscopy subsidy system introduced, charity walk held |

| 2024 | Improving sleep habits | Conducted SAS screening, held charity walk, established JFE Wellness Action 5 |

SH Detecting Illnesses at an Early Stage, Maintaining and Promoting Health for Employees and Their Families

JFE Shoji believes that the health of employees and their families holds the key to the further development of the company and is therefore creating workplace environments in which employees can work with vigor.

Health and Productivity Management Promotion System

Past Initiatives

| Fiscal Year Launched | Purpose | Initiatives |

|---|---|---|

| 2018 | Prevent cancer | Helicobacter pylori tests conducted during regular health checkups |

| New program for subsidizing examination fees for breast cancer and uterine cancer | ||

| Raise employee health awareness | e-learning program based on the importance of regular health checkups, and reducing heart and brain disease | |

| 2019 | Prevent lung cancer and stroke | Measures related to passive smoke (reduction in smoking rate) |

| New program for subsidizing smoking cessation clinic fees | ||

| 2020 | Encouraging employees to exercise as a habit | Encourage participation in the Powering Up Health Care program |

| 2022 | Providing more individualized guidance | Encourage individual consultation to those eligible for specific health guidance |

| 2023 | Early detection of stomach cancer | Gastrointestinal endoscopy tests conducted during regular health checkups |

| 2024 | Strengthening the implementation of specific health guidance | Enhanced collaboration with health insurance associations and medical institutions to thoroughly encourage participation |

| Raising health awareness | Held women’s health seminars |