Steel Industry Initiatives

Initiatives

The Japan Iron and Steel Federation (JISF) Initiatives

Long-term Vision for Climate Change Mitigation

The JISF has been focusing on achieving the goals for 2020 under its Commitment to a Low Carbon Society (renamed the Carbon Neutrality Action Plan in FY2021). Furthermore, in November 2018, the JISF formulated and published its Long-term Vision for Climate Change Mitigation for 2030 and beyond, with JFE Steel playing a central role in its development. This document lays out the industry's challenge for realizing zero-carbon steel and explains the pathway for achieving the 2°C scenario for steelmaking and the necessity of ultra-innovative technologies to achieve the 1.5°C scenario. Also, on February 15, 2021, the JISF announced the government's basic policy of the Japanese steel industry on carbon neutrality for 2050 , declaring that the Japanese iron and steel industry will boldly accept the challenge of realizing zero-carbon steel.

Relevance with the JISF's Long-term Vision for Climate Change Mitigation

JISF's Carbon Neutrality Action Plan

In February 2021, the JISF declared that the Japanese steel industry will boldly take on the challenge of realizing carbon neutrality. The Plan on Commitment to a Low Carbon Society was amended and renamed as the Carbon Neutrality Action Plan, and the Phase II target (2030 target) was revised.

In the Eco Process of the plan, an ambitious 2030 target was set taking into account new perspectives such as the expansion of scrap use as well as the maximum introduction of best available techniques (BATs) based on energy efficiency already among the highest in the world.

Regarding Eco Product, which is intended to reduce GHG emissions at the product use stage, high-performance steel is expected to play a particularly major role in the promotion of offshore wind power and electrification of automobiles, which are among the 14 fields of the government's Green Growth Strategy. Accordingly, the Japanese initiative will accelerate practical global warming measures from a global perspective by making visible the conventional quantitative evaluation of the five types of high-performance steel.

As for Eco Solutions, the JISF will develop a system for introducing appropriate technology for transferring and spreading the production process for decarbonized steel in the Asian regions, where steel production is expected to expand.

Furthermore, regarding Innovative Technology Development, the JISF will take on the challenges of technologies such as direct hydrogen reduction and high-performance steel production using electric arc furnaces under the Green Innovation Fund, in addition to COURSE 50 and ferro-coke.

Overview of the Carbon Neutrality Action Plan

Eco Process

Cut energy-related CO₂ emissions (total volume) in FY2030 by 30% compared to the FY2013 level by adopting BATs to promote energy conservation, using waste plastics, adopting innovative technologies that are currently under development and scheduled to be in use around 2030, and using raw fuel with less CO₂ emissions.

Eco Product

Contribute to CO₂ emissions reduction by domestically and internationally supplying high-performance steel. This steel will reduce CO₂ emissions when used in the final product. The reduction potential in 2030 is estimated to be approximately 42 million t-CO₂ for the five steel products that have been quantitatively evaluated for their contribution to reducing emissions.

Eco Solution

Contribute to reducing CO₂ emissions worldwide by transferring and spreading the Japanese steel industry's advanced energy-saving technologies and facilities to the world's steel industry. Estimated contribution on CO₂ emissions reduction is 80 million t-CO₂ in 2030.

Innovative Technology Development

Contribute to carbon neutrality by boldly developing technologies in the following four areas.

・Hydrogen reduction technology using in-house hydrogen

・Low-carbon technology using CO₂ contained in externally sourced hydrogen or blast furnace exhaust gas

・Direct hydrogen reduction technology

・Impurity removal technology for electric furnace using direct reduced iron

Assessment of the 2021 Carbon Neutrality Action Plan (Phase II) Results (JISF)

Total volume of energy-related CO₂ emissions in FY2021 was 163.09 million tonnes, 31.34 million tonnes, or a 16.1% decrease from FY2013. The achievement rate of the FY2030 target (to reduce 30% from FY2013) has progressed to 53.7%. Energy-related CO₂ emissions and energy consumption are both declining, given continued energy-saving efforts.

While the energy efficiency of the Japanese steel industry is among the highest in the world, vigorous efforts are made to promote greater energy savings by having businesses engaged in this effort draw upon subsidies to promote investment in saving energy and other actions.

Revolutionary Iron and Steelmaking Process Development

COURSE50

About 30% of CO₂ emissions can be reduced through hydrogen reduction along with separation and capture of CO₂ from blast furnace gases. The first facility is expected to come online by 2030, followed by other plants by 2050.

Ferro-Coke

Ferro-coke is an innovative raw material for blast furnaces that is made by mixing low-grade coke and iron ore. In this energy-saving technology, metallic iron acts as a catalyst, reducing the amount of coke required in the furnace and thus significantly reducing CO₂ emissions in the iron making process.

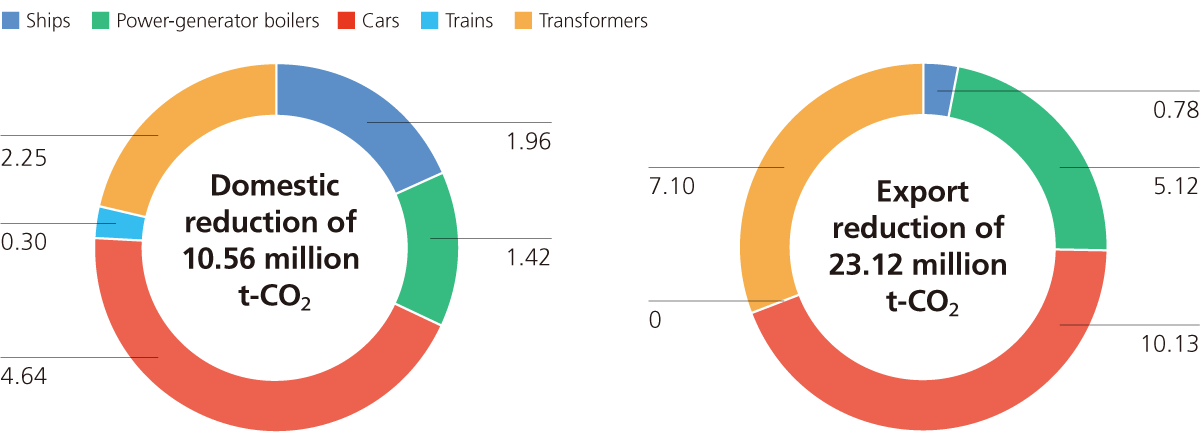

Reduced CO₂ Emissions through High-performance Steel Materials (Effects of Eco Products)

The Japan Iron and Steel Federation (JISF) calculates the CO₂ emissions reduction impact of using high-performance steel materials. It is estimated that the use of five major high-performance steel materials in cars, transformers, ships, power generator boilers, and trains in Japan and overseas* (FY2021 production: 6.69 million tonnes, 7.3% of crude steel production) helped reduce CO₂ emissions by 33.69 million tonnes (10.56 million tonnes in Japan, 23.12 million tonnes overseas) in FY2021.

*Estimates made by the Institute of Energy Economics, Japan

*The five materials are steel sheets for automobiles, directional electrical steel sheets, thick steel sheets for shipbuilding, steel tubes for boilers, and stainless steel sheets.

*Evaluations for domestic figures are made starting from FY1990. For exports, automobile and ships have been evaluated since FY2003, steel pipes for boilers since FY1998, and electrical steel sheets since FY1996.

CO₂ Reduction Resulting from the Use of Five High-performance Steel Materials in Japan and Abroad (FY2021)

Global Scale Initiatives

Global Actions to Address Global Warming

ISO 14404 is an international standard proposed by the Japan Iron and Steel Federation (JISF) to the International Organization for Standardization (ISO) as a methodology for the globally unified calculation of CO₂ intensity from iron and steel production, ultimately to assess the energy efficiency of steelworks. The Japanese steel industry is addressing global warming through international public-private collaborations, including ISO 14404-based assessment of steelworks in developing countries and recommending specific technologies best suited to India and ASEAN countries. It is continuing this effort together with the Ministry of Economy, Trade and Industry (METI) in order to enhance ISO 14404 so it can be applied to steel manufacturing facilities with more complex structures.

JFE Steel is also addressing global warming by participating in international activities, such as the Japan India Public and Private Collaborative Meeting, the Japan-ASEAN Steel Initiative and the Japan-China Steel Industries Exchange. In addition, JFE Steel is involved as a member of World Steel Association (WSA)'s Climate Action data collection programme, which uses ISO 14404 as the standard for measurement and calculation.

WSA: Climate Action data collection programme

WSA Climate Action data collection programme certification

Contribution to Developing the LCA of Steel Material

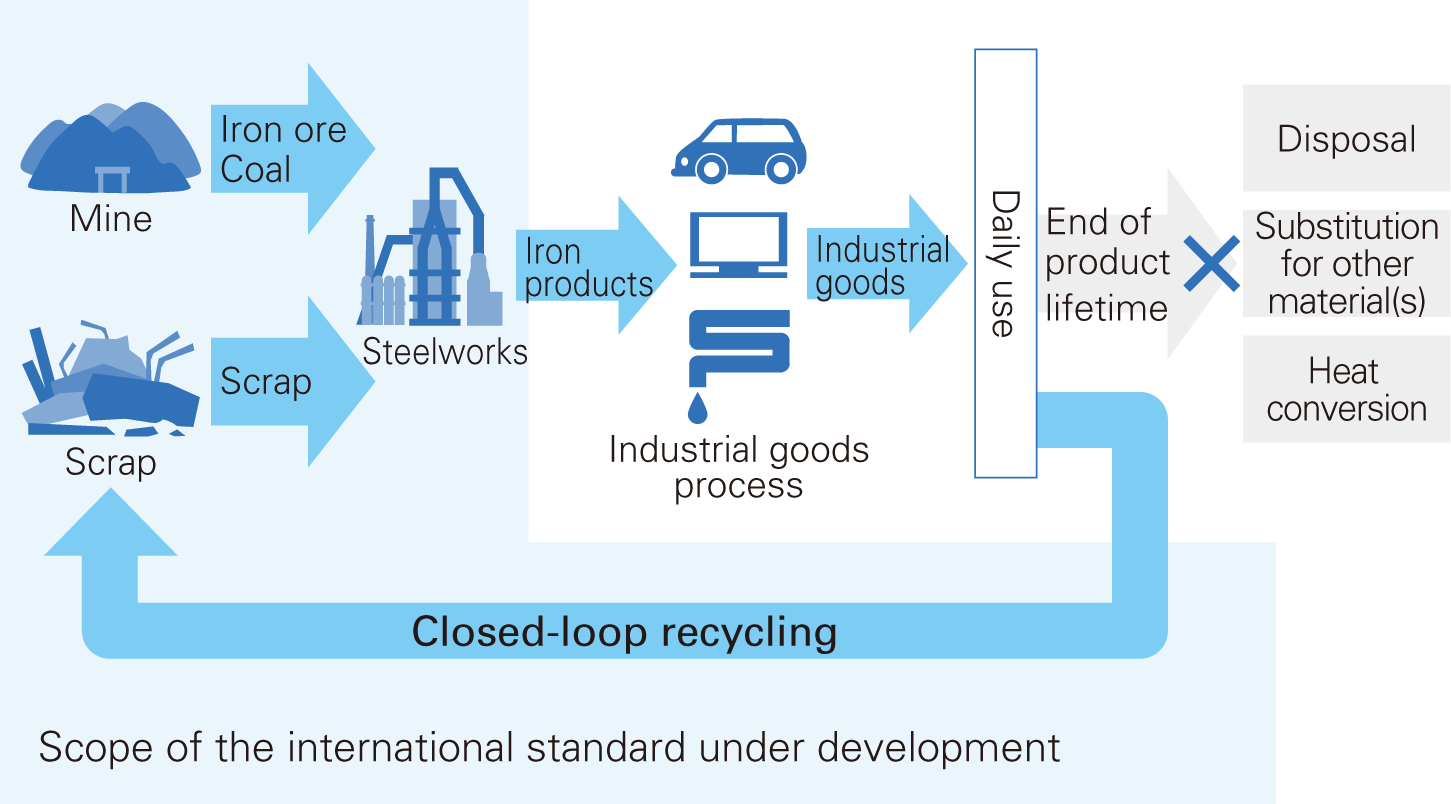

Accurately evaluating the environmental impact of products requires assessment and quantification of impact over their entire life cycles, from raw resource mining to material production, product manufacture, use, and final disposal. Life cycle assessment (LCA) is one evaluation method.

After final products such as automobiles and buildings finish their mission in society, all of their steel components can be recycled and reused. This closed loop recycling ability is an excellent characteristic of steel materials. Taking this into account through LCA reveals that steel can be viewed as having extremely low environmental impact compared to other materials.

JFE Steel played a major role in the development of ISO 20915 (Life Cycle Inventory Calculation Methodology for Steel Products) and JIS Q 20915 (Life Cycle Inventory Calculation Methodology for Steel Products), initiatives led by the Japan Iron and Steel Federation (JISF), which takes into account the impact of recycling and provides life cycle inventory (LCI) calculation methods specific to steel products.

In addition, 15 Japanese manufacturers of blast furnaces and electric arc furnaces joined forces to calculate the Japanese average for LCI of different steel products. Calculations based on their FY2018 operational data were also published.

JFE Steel acquired EcoLeaf labels, the Japan Environmental Product Declaration program run by the Sustainable Management Promotion Organization (SuMPO), for three steel sheet products for cans (tinplate, laminated steel sheet JFE Universal Brite, and tin-free steel), five building material products (H-beams, Super High Slend® H beams, extra-thick H beams, construction steel plates, and construction steel columns) and three steel plate products (for offshore structures and wind power equipment, ship building, and UOE steel pipes). We will continue to leverage EcoLeaf labels to help customers promote environmental protection and to strengthen communications with them.

Life Cycle of Steel Materials

Related Links

The Japan Iron and Steel Federation (JISF): Climate Change Policy page

The Japan Iron and Steel Federation (JISF): LCA of Steel Products page

The Japan Iron and Steel Federation (JISF): Publication of ISO 20915

The Japan Iron and Steel Federation (JISF): Publication of JIS Q 20915