Efficient Use of Resources

Basic Policy

Economic growth in emerging countries is intensifying the need to conserve non-renewable resources and prevent pollution. Iron can easily be separated and is thus highly recyclable. It can be recycled and reused to make other steel products infinite times (closed-loop recycling). The JFE Group is leveraging each Group company's strengths to enhance resource recycling through recycling co-products from iron and steelmaking, reducing waste at construction sites, and promoting the global recycling of steel scrap.

We continue to pursue efficient uses of resources in both the production and product/service phases of its businesses, through steel scrap recycling, biomass fuel production and waste-to-energy power generation.

Targets and Results

As we acknowledge that the efficient use of resources is a key environmental issue for manufacturers, we set high-level targets corresponding to the business of our Group companies and monitor the results. The Group companies have consistently fulfilled KPIs for material CSR issues every year up to FY2020 and established environmental practices. We continue to work on efficiently using resources toward the following high-level targets.

Targets and Results for FY2022 and Targets for FY2023

| Operating Company |

FY2022 Targets | FY2022 Results and Initiatives |

FY2023 Targets |

|---|---|---|---|

| JFE Steel | Recycling rate of co-products: 99% or higher |

Recycling rate of co-products: 99.5% |

Recycling rate of co-products: 99% or higher |

| JFE Engineering | Recycling rate at construction sites

•Recycling rate of rubble: at least 99.5% •Recycling rate of sludge: at least 95.0% •Recycling rate of industrial waste: at least 85.0% |

Recycling rate

•Recycling rate of rubble: higher than 99.9% •Recycling rate of sludge: higher than 99.0% •Recycling rate of industrial waste: higher than 84.4% |

Recycling rate at construction sites

•Recycling rate of rubble: 99.5% or higher •Recycling rate of sludge: 95.0% or higher •Recycling rate of industrial waste: 85.0% or higher |

| Recycling rate of office recyclable waste (Yokohama head office): at least 98.0% | 98.7% | Recycling rate of office recyclable waste (Yokohama head office): 98.0% or higher | |

| JFE Shoji | Global recycling of steel scrap •Exceed FY2020 scrap trade volume (FY2024 target: +5% from FY2020) |

Scrap trade volume: -14% from FY2020 | Global recycling of steel scrap •Exceed FY2020 scrap trade volume (FY2024 target: +5% from FY2020) |

Initiatives

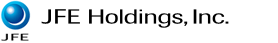

Reducing Generation and Emission of Co-products and Reusing Co-products

JFE Steel carefully controls the generation and emission of iron and steelmaking slag (a co-product), iron dust from blast furnaces and converters, sludge from water treatment facilities, and other co-products by setting targets to improve recycling rates. Dust and sludge with high iron content are recycled as raw materials for steelmaking. Iron and steelmaking slag is effectively recycled for reuse in cement and other construction materials. The company is also promoting its use as environment recovery material such as Marine Stone™, which works effectively as a base for the adhesion of organisms and for improving the marine environment. As a result of these efforts, the company accomplished a 99.5% recycling rate for slag, dust, and sludge in FY2022, fulfilling the target of 99% or higher, and it is committed to consistently achieving the target.

Landfill of Co-products and Recycling Rates

*22 JFE Steel consolidated subsidiaries in Japan.

For more quantitative data related to co-products, please refer to the following information.

Promoting Recycling

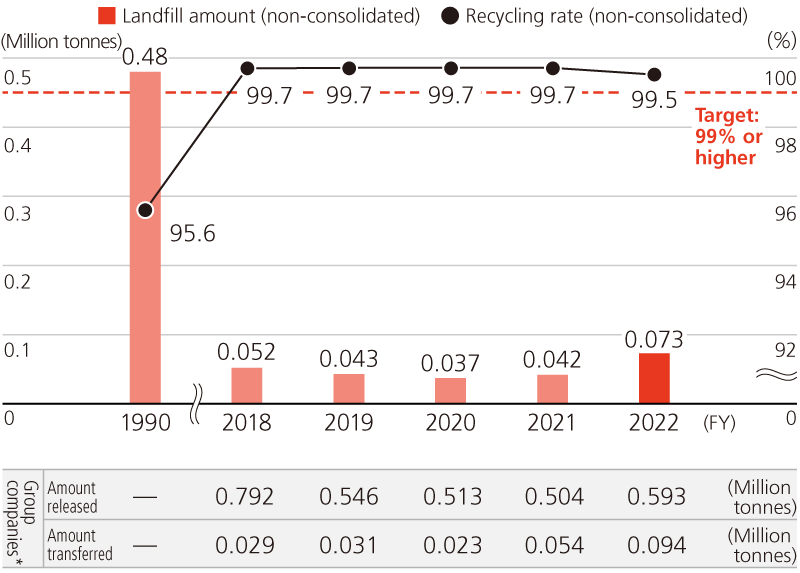

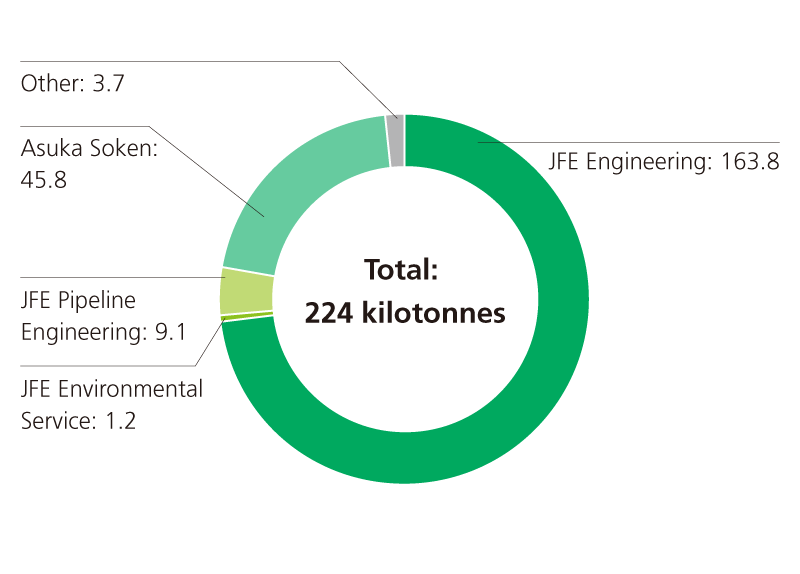

Most of JFE Engineering's waste is either rubble and sludge discharged from construction sites or industrial waste discharged by the Tsurumi and Tsu works. The company is seeking to reduce industrial waste while also resource recycling through various measures, such as setting environmental goals for recycling rates and properly separating waste on-site before sending it to disposal companies known for achieving high recycling rates. It also complies with the Plastics Resource Circulation Act, enforced in Japan in April 2022, by including initiatives for plastics recycling in its environmental target.

The Yokohama head office sets target recycling rates for office recyclable waste and maintains its efforts to reduce waste (encouraging double-sided copying), reuse (setting up collection boxes for plastic folders and plastic business card cases and recovering label printer cartridges), and recycle (thoroughly separating waste). The JFE Engineering Group is also helping to realize a recycling-oriented society through its PET bottle and food waste recycling initiatives.

JFE Engineering Group Waste Disposal for FY2022

*Data cover JFE Engineering and 11 consolidated subsidiaries in Japan.

Waste Generated at Construction Sites

For more on waste generated at the steelworks, please refer to the following information.

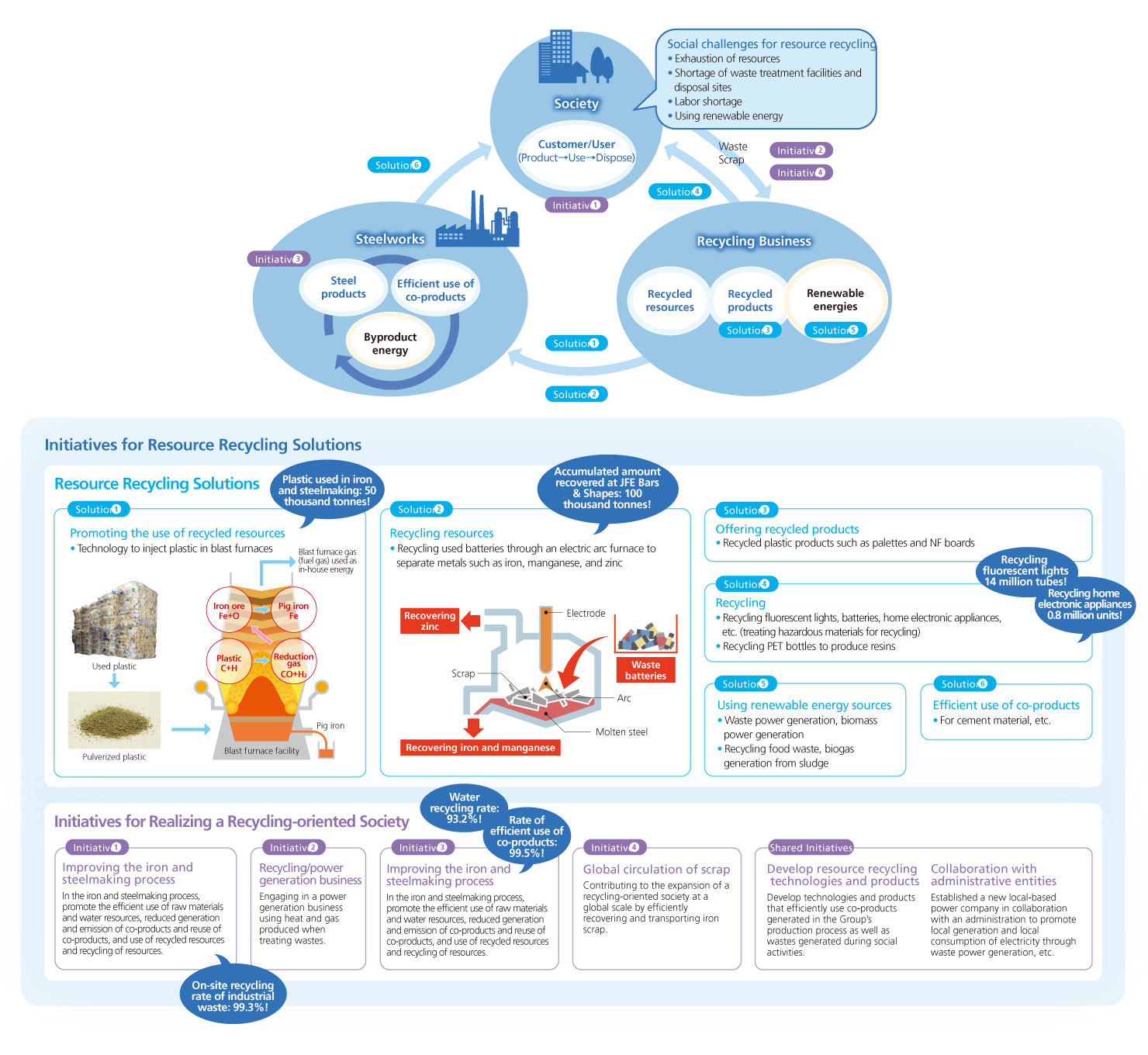

Resource Recycling Solutions

The JFE Group is involved in establishing a recycling-oriented society through a variety of initiatives. Steelworks promotes the efficient use of raw materials, water, and other resources in the process of iron and steelmaking in addition to encouraging the application of recycled resources such as used plastics for blast furnaces. Moreover, we a striving to more efficiently use co-products generated in the iron and steelmaking process through initiatives such as the international recycling of steel scrap. By leveraging the highly recyclable quality of steel, we are also developing product that contribute to addressing the issue of plastic waste.

In the engineering field, we produce biomass fuel from food waste and sewage sludge, constructing plants, and other infrastructures for waste power generation and offer resource recycling solutions by operating these facilities directly or under contract. In addition, we are pursuing a circular economy by developing PET bottles and a plastics recycling business as well as an energy supplying business.

For JFE Steel and JFE Engineering's recycling businesses, please refer to the following information.

List of JFE Group's recycling businesses

For more on this, please refer to the following information.

Development and Provision of Eco-friendly Processes and Products

Reducing Plastic Waste Reduction by Manufacturing Cups from Highly Recyclable Steel

Under the logo Steelish™ , a combination of “steel” and “stylish,” JFE Steel is engaged in an initiative to expand the use of stylish, recyclable steel products that would introduce a change in daily lifestyles and help propel the global effort to tackle plastic pollution. For instance, JFE Steel proposes single-use steel cups as an alternative to disposable plastic cups. Steel cups are light and sturdy, with a thin rim that feels smooth against the lips, and they are able to keep drinks hot or cold for a long time, as well as being infinitely recyclable into other steel items and easier to recycle than plastic.

To this end, JFE Steel launched the project “BETTER RECYCLE Shonan” in 2021 and has since been involving customers in the development of disposable steel cups, the first time the company has adopted this approach. The project team, made up of members from IBLC Co., Ltd. and “Shonan Style” (a magazine published by EDITORS, Inc.) as well as JFE Steel, sought advice and cooperation from local governments and plastic disposable suppliers in the Shonan area and created a prototype for an eco-friendly disposable steel cup. The prototype and the Steelish™ initiative were presented at “Carnival Shonan 2022 ,” an event held at the Kanagawa Municipal Tsujido Kaihin Park in November 2022 to explore turning the Shonan beaches into the first zero-waste beaches in Japan.

In March 2023, steel cups were used at “Nakame Challenge Cup 2023 ,” an event hosted by Asahi YOU. US, Ltd. and the Nakame Area Management Association to eliminate disposable plastic bottles discarded by people viewing cherry blossoms in Nakameguro and raise awareness of plastic pollution, food loss, and other sustainability issues.

JFE Steel is committed to playing its part in fostering public awareness about climate change and plastic pollution issues and to achieving the SDGs by developing steel solutions that meet the needs of customers and society as a whole.