Water Security

Basic Policy

The JFE Group uses large quantities of fresh water for cooling and cleansing products and facilities in its core business of steel manufacturing. For this reason, the efficient use of water resources with due consideration to the source of the water and stakeholders in the area is a key challenge. In response, we have established a system for reducing water intake by maximizing the use of recycled water at our steelworks. We will continue our efforts to reduce environmental impact by reducing water consumption through more efficient use.

And while we have always taken measures against meteorological disasters such as droughts and floods at our manufacturing sites in Japan, we are further reinforcing them in anticipation of the increased frequency and severity of weather events associated with climate change by securing alternative means and raising the height of embankments. We also seek to identify water-related risks throughout our business sites and supply chain in Japan and overseas, such as the risk of drought at the source of water intake and pollution at the point of discharge. In areas under water stress, we will respond appropriately through dialogue with stakeholders.

System

The JFE Group recognizes the issue of water resources as a risk that may significantly impact operations, and we have taken action against meteorological disasters such as droughts and floods. In recent years, we have been seeking to adequately identify and manage water risks based on the assumption that disasters due to climate change will increase in frequency and severity.

With regard to Group risk management, the Group Sustainability Committee, under the leadership of the CEO, who heads the JFE Group CSR Council, discusses, supervises, and guides Group-wide environmental initiatives, including the proper use of water resources.

There were no violations of environmental laws or regulations related to water quality in FY2022, and no fines or penalties were imposed.

Targets and Results

We acknowledge the use of water resources as a key environmental issue for manufacturers. Because the JFE Group uses large quantities of water in its core business of steel manufacturing, the Group sets high goals for water resource recycling. We defined KPIs for material CSR issues and consistently met them every year up to FY2020. This effort helped us to establish environmental practices. We will maintain our efforts to reduce water consumption toward the following high-level targets.

Target and Result for FY2022 and Target for FY2023

| Operating Company |

FY2022 Target | FY2022 Result and Initiative |

FY2023 Target |

|---|---|---|---|

| JFE Steel | Maintain efficient use of water Recirculated water usage rate: 90% or higher | Recirculated water usage rate: 93.2% | Maintain efficient use of water Recirculated water usage rate: 90% or higher |

Initiatives

Analyzing and Responding to Water Risks

As part of overall risk management, we identify, analyze and evaluate water risks based on past incidents of droughts and floods in the JFE Group's businesses, forecast data from the Meteorological Agency and results of our scenario analysis. In particular, we consider as key risks the damages to business sites and disruption of the supply chain caused by restrictions on water intake due to droughts or increasing severity of meteorological disasters. In response, we are further reinforcing measures such as using recycled water, securing alternative means, and strengthening drainage facilities.

Furthermore, to ensure the stability of our steel business's procurement throughout its supply chain, we are taking initiatives to reduce risks by evaluating them based on past data concerning water-related disasters and results of scenario analysis for materials such as coal and iron ore, securing alternative routes of procurement and diversifying suppliers.

JFE Steel identifies and evaluates water-related risks based on past incidents of damage caused by droughts and floods, forecast data from the Meteorological Agency and results of scenario analysis. We conduct a further evaluation of water risks around each manufacturing site from different perspectives by also using the World Resource Institute (WRI)'s Aqueduct, a mapping tool for evaluating overall water risks from droughts and floods in each region around the world.

According to the WRI's assessment in May 2023, water risks for all of Japan are not designated at a high level or above, but there will be risks of water shortages and flooding due to weather conditions in the future (2030s and 2040s). JFE Steel identifies steelworks under such weather risks and takes measures such as business continuity planning.

Efficient Use of Water Resources

A large amount of water is used in the iron and steelmaking process to cool facilities and process products. The target water recycling rate at JFE Steel is 90% or more, which is extremely high considering the amount evaporated when water is used. We are striving to improve the recycling rate by adopting purification processes such as biological and chemical wastewater treatments, and we have been successfully achieving the target. Our recycling rate of industrial water in FY2022 maintained a high level of 93.2%.

Industrial Water Accepted/Circulated

*¹Industrial water circulated (%) = (Total amount used - industrial water accepted)/total amount used X 100

*²22 JFE Steel consolidated subsidiaries in Japan.

JFE Engineering and each Group company strive to use water efficiently at their business sites.

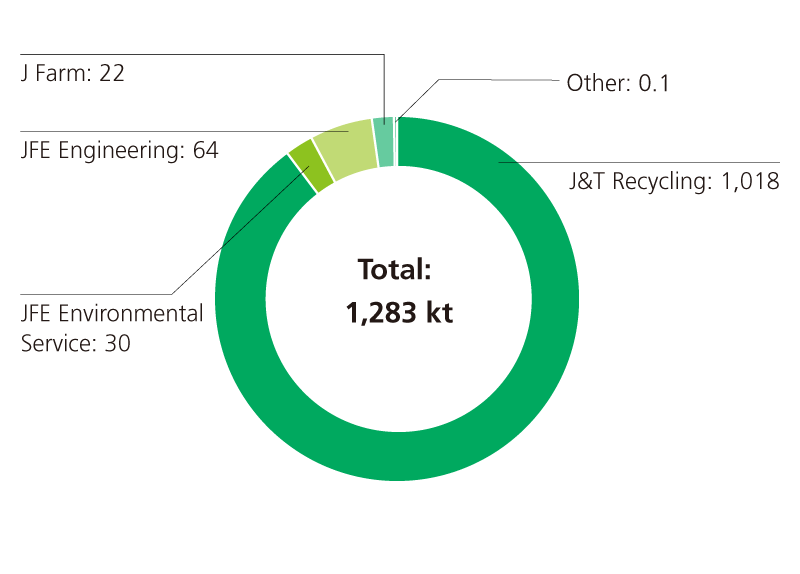

JFE Engineering Group's Water Consumption for FY2022

*Data cover JFE Engineering and 7 consolidated subsidiaries in Japan.

For more on quantitative data related to water, please refer to the following information.