Value of Steel

Appealing Qualities of Steel that Create Safe, Comfortable Lives for a Prosperous Global Future

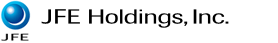

Iron makes up approximately 30% of the Earth’s mass. Because of its rich reserves, steel can be mass produced at very low cost. Compared to other materials, the environmental impact of its production is extremely low and it has excellent recyclability. Steel can be recycled repeatedly and reborn as various products (closed-loop recycling) with little or no environmental impact, contributing to the sustainable growth of our society.

Life Cycle Assessment of Steel

Steel’s excellent recyclability contributes to the creation of a sophisticated value chain encompassing three components: Produce, Use, and Recycle. Steel products can be repeatedly reborn as various products. It is therefore important that the environmental impact of steel be assessed across its entire life cycle, including at the recycling stage. JFE Steel participates as a key member in an initiative led by the Japan Iron and Steel Federation (JISF) to quantify the environmental impact of the entire life cycle of steel products and developed the ISO/JIS standard* calculation methodology. Corresponding to this standard, materials with higher recyclability are found to have lower environmental impact such as on global warming.

Fifteen blast furnace and electric arc furnace steel manufacturers operating in Japan, including JFE Steel, have compiled and published the national average value for life cycle inventory (LCI) data for different types of steel products for FY2018.

*ISO 20915: Life cycle inventory calculation methodology for steel products (November 2018)

JIS Q 20915: Life cycle inventory calculation methodology for steel products (June 2019)

Contribution to the Development of Calculation in LCA

Produce

High Economic Efficiency and Low Environmental Impact

The stable mass production of steel serves as the foundation for daily life and society. CO2 generated by the manufacturing process of steel is extremely low compared to other materials, making it an environmentally sound material. Steel is an essential for society’s sustainable development and to create safe, comfortable lives for people everywhere.

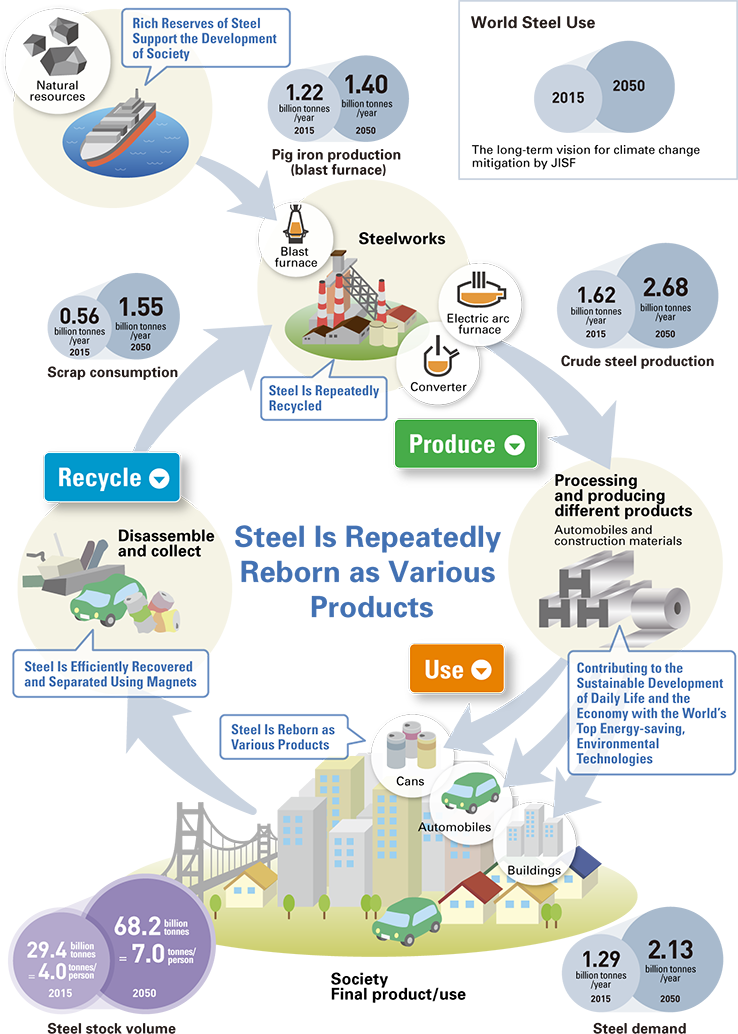

Earth, a Planet of Iron (Abundant Resources)

As much as 85% of the Earth’s metal resources are iron ore (180 billion tonnes).

Recoverable Reserves of Iron Ore on the Earth

Source: Mineral Commodity Summaries (2022)

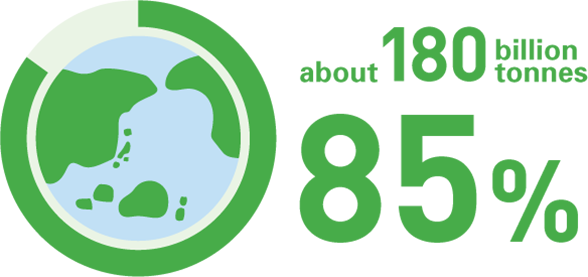

Mass Production at Low Cost

With rich reserves and a long history of technological development, iron is mass produced at reasonable prices and supplied stably, thereby contributing to the sustainable growth of society.

Global Demand (2020)

Research: JFE Holdings

Price*

Research: JFE Holdings

*Cost of producing one unit weight of iron is indexed at 1 for comparison with other materials.

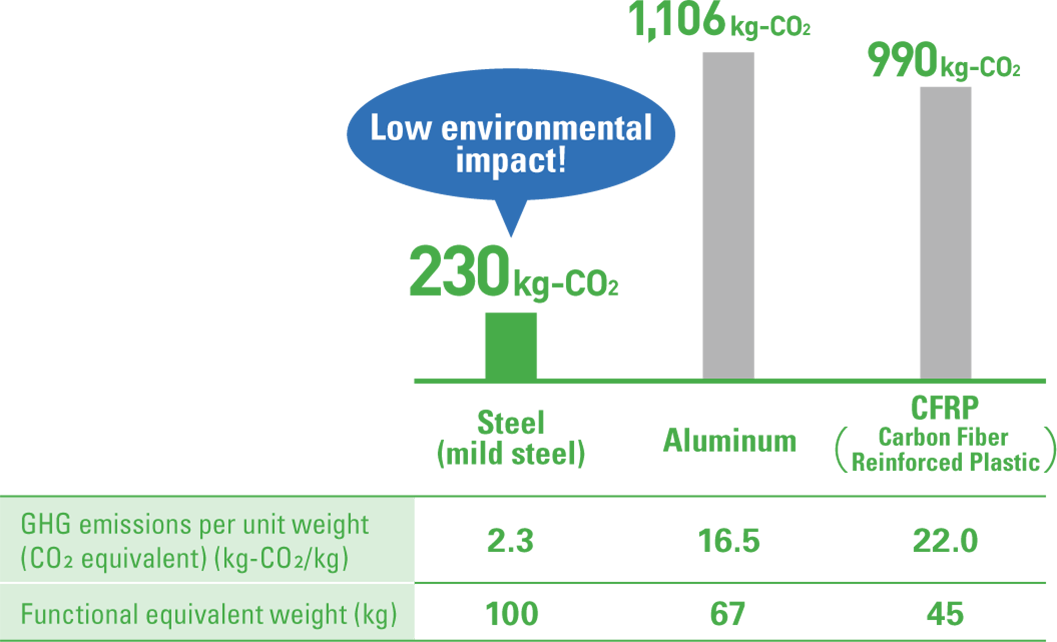

Extremely Low Environmental Impact at the Manufacturing Stage when Compared to Other Materials

Greenhouse gas (GHG) emissions of steel at the manufacturing stage is approximately one-fourth to one-fifth of that of aluminum and carbon fiber with equivalent functionality.

GHG Emissions at the Manufacturing Stage of Materials (CO2 equivalent)

(kg-CO2/100kg of steel equivalent parts)

Source: Compiled from data disclosed by WorldAutoSteel

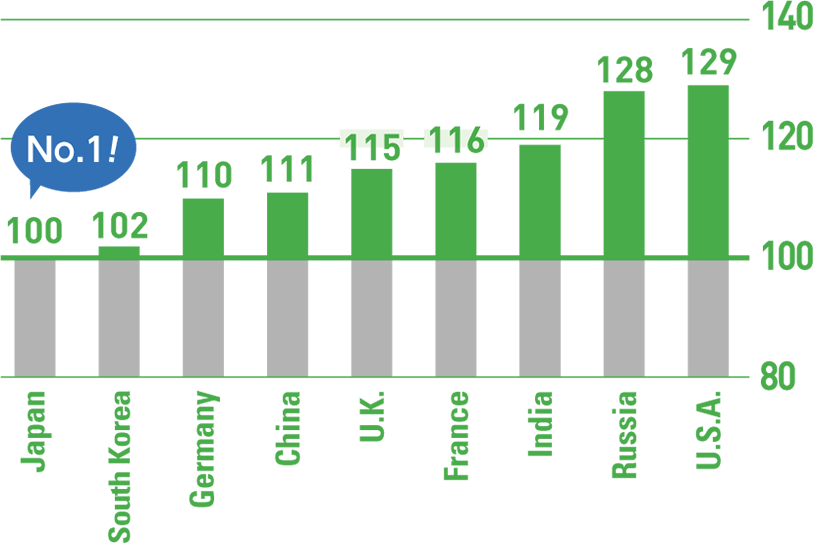

Japan’s Steel Industry Boasts the Highest Energy Efficiency in the World

Japan’s steel industry (converter steel) produces steel with the lowest environmental impact compared to other major countries. This is a result of its longstanding efforts toward environmental conservation, including developing and spreading the use of energy-saving technologies.

World’s Quotient, with Japan as 100 (2019)

Source: Research Institute of Innovative Technology for the Earth (RITE)

Use

Foundation of Daily Life and Society

The use of steel impacts the environment less than other materials. For example, making automobile frames with high tensile strength steel sheets, which have a reduced thickness but retain their strength, considerably decreases the weight while maintaining crash performance, thereby helping to reduce CO2 emissions for society as a whole.

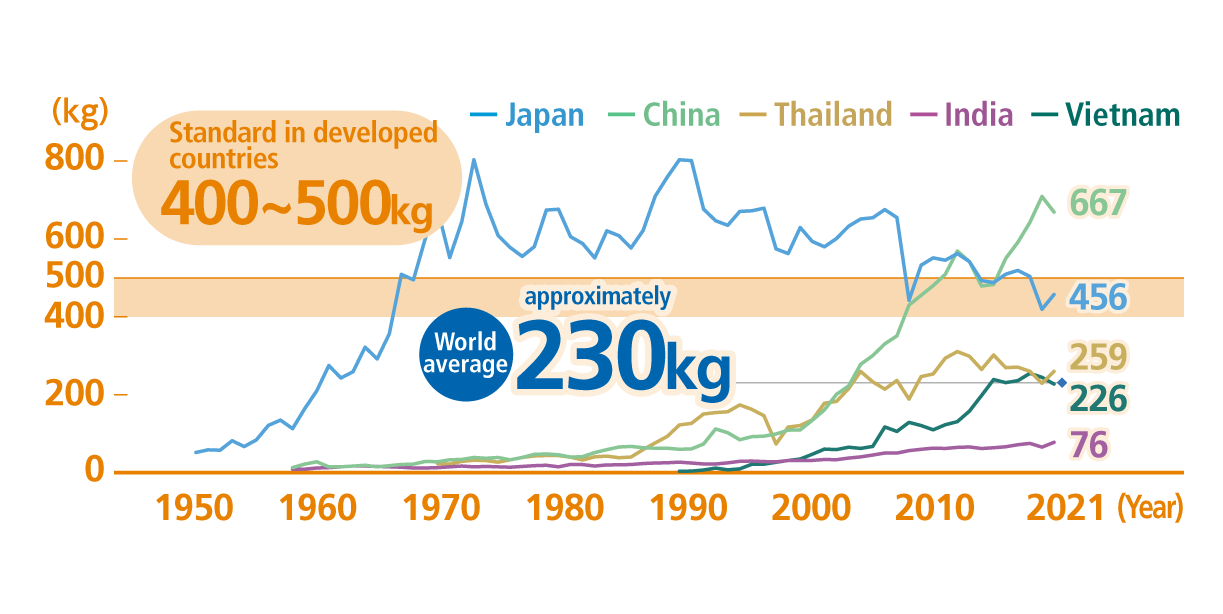

Potential to Grow on a Global Scale

Global average of annual consumption of steel is approximately 230 kg per capita. The long-term global demand for steel is expected to keep growing alongside the economic development of emerging countries.

Trends in Annual Steel Consumption per Capita by Country (kg/person/year)

Source: World Steel Association

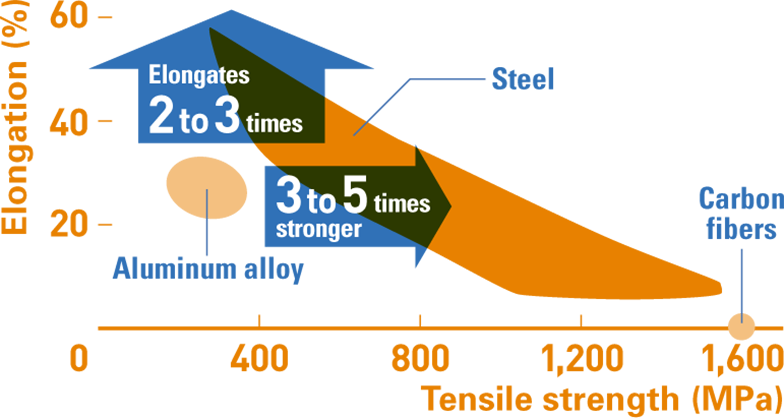

Potential for Evolution

Steel can be elongated two to three times more than aluminum at the same rigidity and is three to five times stronger at the same extended rate, making it the optimal material for new world-class structures such as TOKYO SKYTREE. And yet there is still potential for further evolution. The emerging needs of society will advance the development of steel and contribute to a productive future.

Comparison of Strength and Elongation between Steel, Aluminum, and Carbon Fiber

Research: JFE Holdings

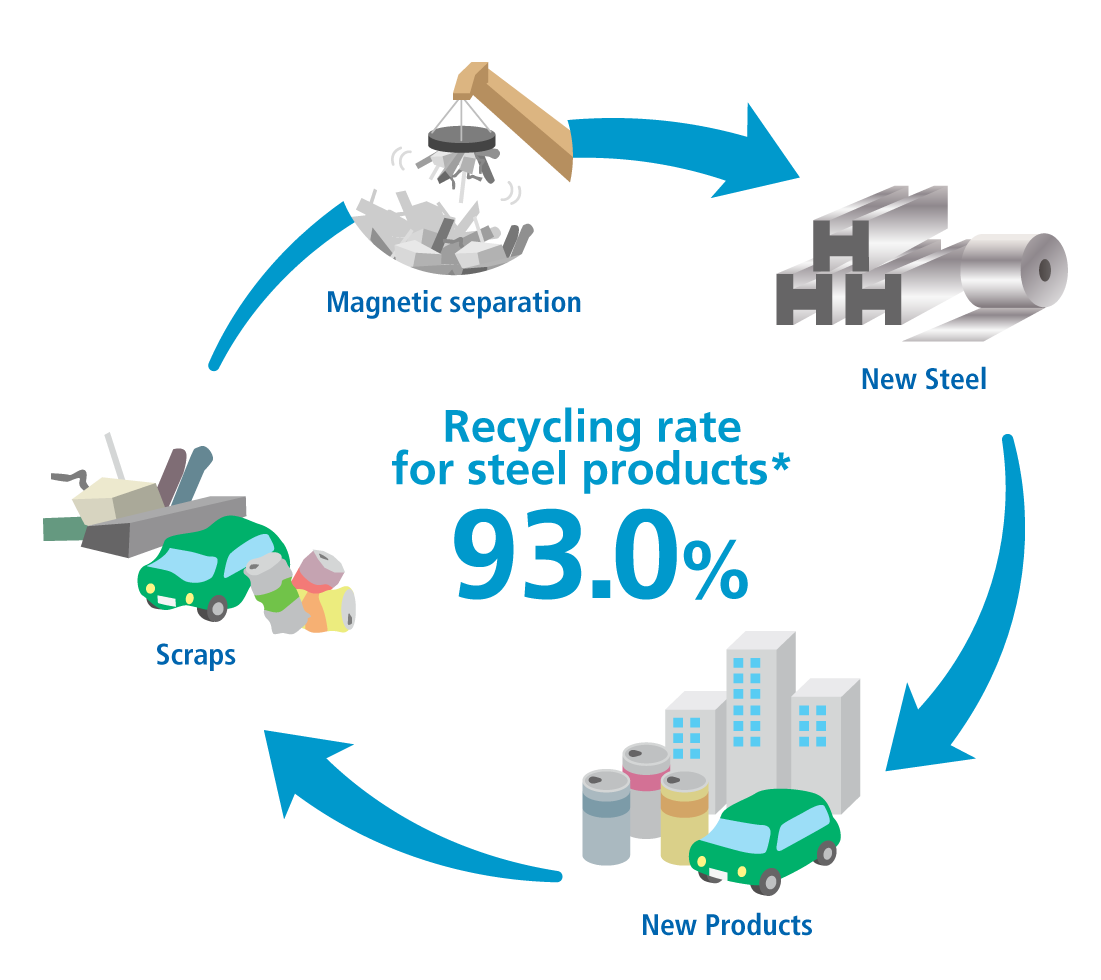

RecycleExcellent Recyclability

Steel is a highly recyclable material that can be easily recovered and separated using magnets. It can be efficiently recovered, separated, and recycled into high-quality, high-functioning products over and over again through closed-loop recycling.

Closed-loop Recycling of Steel

Steel can be recycled a number of times as a raw material for steel products while retaining its original properties. Closed-loop recycling is superior to open-loop recycling* in terms of sustainability, because closed-loop recycling reduces the consumption of natural resources, as well as the amount of environmentally hazardous substances and wastes.

*In open-loop recycling, the material recycling process involves two types of finite recycling which are thermal recycling and cascade recycling. Thermal recycling means that heat generated by incineration is recovered while cascade recycling indicates recycling the material accompanied by the degradation or alteration of the material’s properties.

Closed-loop Recycling

Source: The Japan Iron and Steel Federation