Prevention of Pollution

Basic Policy

The JFE Group regards co-existence and mutual prosperity with local communities, the global environment, and society at large as a critical managerial challenge in terms of business continuity. It strives to control air and water pollutant emissions and aggressively invests in environmental protection. Related internal controls and education are steadily being strengthened as well. Also, the transfer and widespread application of proprietary technologies, mainly in developing countries, contribute to pollution prevention on a global scale.

Management System

The JFE Group works to reduce environmentally hazardous substances generated from its business activities, takes actions to keep air, water, and other resources clean, and manages these matters Group-wide. In addition to management and supervision carried out by specialized committees set up at each operating company, operating companies' environmental management activities, including compliance with pollution prevention regulations, risk management, and implementing measures are reported to the Group Sustainable Committee, formed under the JFE Group CSR Council and chaired by the CEO of JFE Holdings, for Group-wide discussion, supervision, and guidance.

Targets and Results

Acknowledging the prevention of pollution as a key environmental concern for manufacturers, the JFE Group has set high-level targets to achieve and maintain the low emission of air pollutants generated from the steelmaking and other processes based on the action plan formulated by the Japan Iron and Steel Federation. Those targets were defined as KPIs for material CSR issues until FY2020 and were consistently met every year, while our efforts to achieve them enabled us to establish environmental practices. We continue to maintain the emission of pollutants at low levels and prevent environmental pollution toward achieving the following high-level targets.

Targets and Results for FY2022 and Targets for FY2023

| Operating Company |

FY2022 Targets | FY2022 Targets and Initiatives |

FY2023 Targets |

|---|---|---|---|

| JFE Steel | Continue efforts to keep NOx and SOx emissions at low levels | Continuously maintained NOx and SOx emissions at low levels | Continue efforts to keep NOx and SOx emissions at low levels |

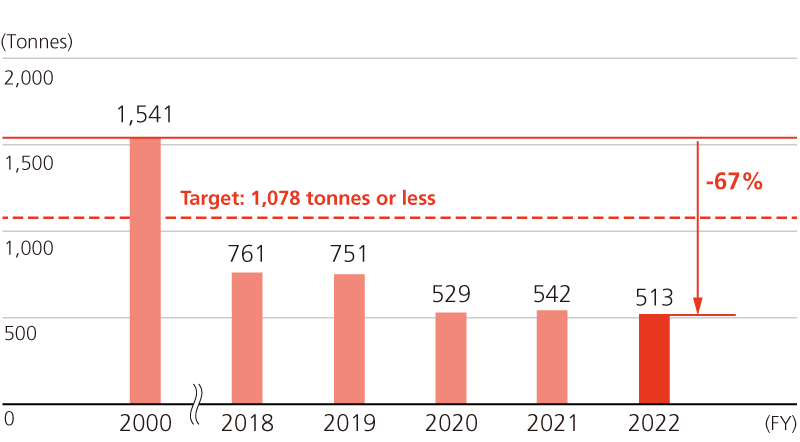

| VOC emissions: -30% from FY2000 (1,078 t or less) | VOC emissions: -67% from FY2000 (513 t) | VOC emissions: -30% from FY2000 (1,078 t or less) | |

| Benzene emissions: -80% from FY1999 (46 t or less) | Benzene emissions: -93% from FY1999 (17 t) | Benzene emissions: -80% from FY1999 (46 t or less) | |

| Dichloromethane emissions: -40% from FY1999 (46 t or less) | Dichloromethane emissions: -68% from FY1999 (25 t) | Dichloromethane emissions: -40% from FY1999 (46 t or less) | |

| JFE Engineering | Continue efforts to keep NOx and SOx emissions at low levels | Maintained low emissions as results were significantly less than the amount equivalent to the total annual volume restriction

・NOx : 126.6 Nm³ (18,000 Nm³) ・SOx : 41.6 Nm³ (100 Nm³) |

Continue efforts to keep NOx and SOx emissions at low levels |

Initiatives

Controlling Air Emissions

JFE Steel is installing low-nitrogen oxides (NOx) burners in reheat furnaces, switching to low-sulfur fuels and deploying desulfurization and denitration devices in sintering plants, all major sources of sulfur oxides (SOx) and NOx emissions. It has concluded agreements with local administrations that stipulate conditions that are stricter than the total volume restrictions required by the Air Pollution Control Law. The company is continuing to further control emissions at a level that is less than the amount set forth in the agreement. In addition, the company suppresses dust dispersion through measures that include enhancing on-site cleaning, installing sprinklers and windbreak fences in raw material yards, and improving the performance of dust collectors.

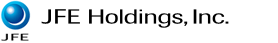

SOx Emissions

*10 JFE Steel consolidated subsidiaries in Japan.

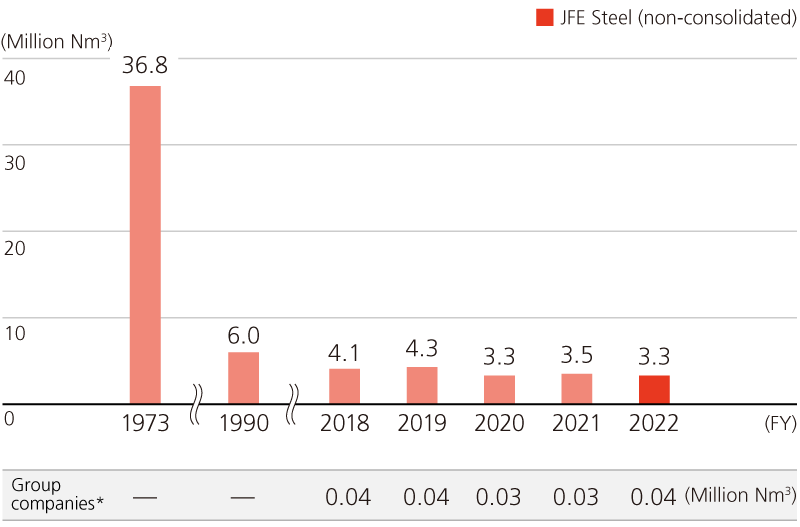

NOx Emissions

*11 JFE Steel consolidated subsidiaries in Japan.

To ensure compliance with the Air Pollution Control Law and relevant local regulations, JFE Engineering properly manages facilities that emit soot and smoke at its Yokohama head office, Tsurumi works, and Tsu works, so NOx and Sox emissions from those facilities are maintained at a level sufficiently lower than the total annual volume restriction (NOx: 18,000 Nm³, Sox: 100 Nm³). In addition, efforts are being made at construction sites to protect the environment through the use of construction machinery and on-site vehicles in compliance with the Automotive NOx and PM Law and Act on Regulation, Etc. of Emissions From Non-road Special Motor Vehicles (Off-Road Vehicle Law).

Preventing Water Pollution

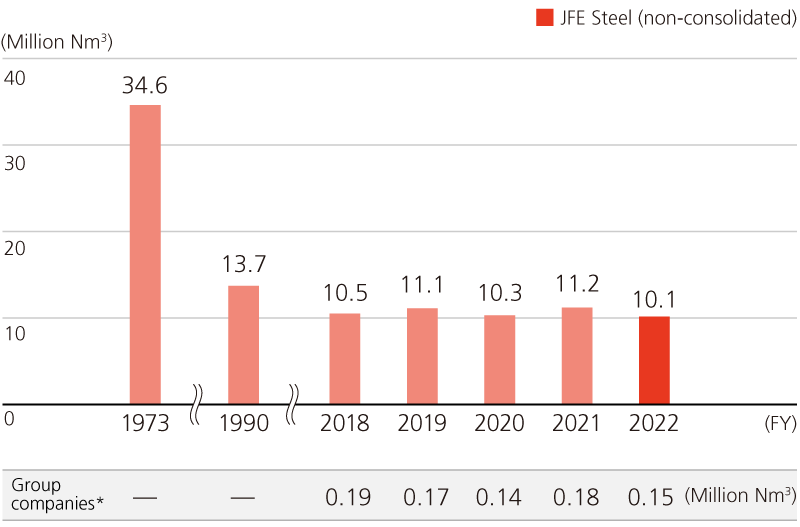

JFE Steel strives to reduce its environmental impact on waterways by thoroughly purifying water used in iron and steelmaking processes before releasing it into public waterways or sewers. The company has concluded agreements with the administrative entity in each area that set out more rigorous effluent standards, compared to those stipulated under the Water Pollution Prevention Act. It also established a strict voluntary control standard to improve water quality. For FY2022, chemical oxygen demand (COD), the water-quality index for wastewater, was 2.8 tonnes per day.

Chemical Oxygen Demand (COD)

*10 JFE Steel consolidated subsidiaries in Japan.

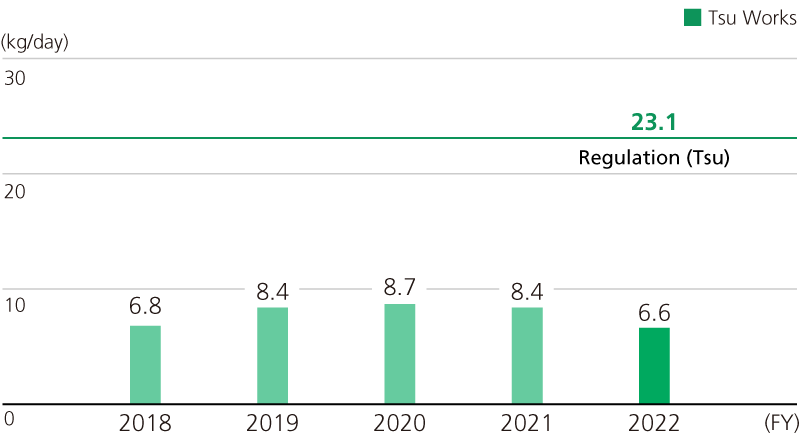

Wastewater from the JFE Engineering Yokohama head office, Tsurumi works, and Tsu works, is released into public waterways or sewer systems. Nitric oxide, phosphorus, and COD in the wastewater are measured on a regular basis and effectively managed in accordance with the Water Pollution Prevention Act and Sewerage Act.

Chemical Oxygen Demand (COD) in Wastewater Released Publicly

*This report uses the maximum value of each year.

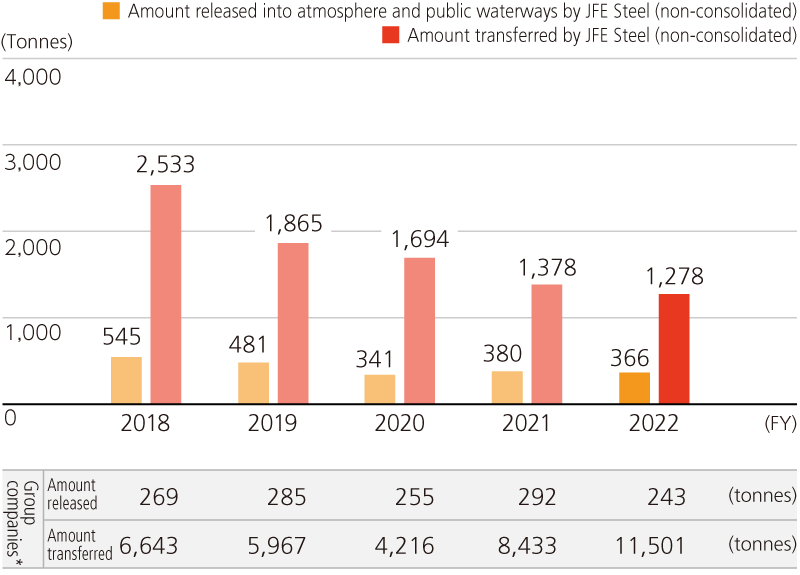

Management of Chemical Substances and Emission Control

JFE Steel lowers its environmental impact by voluntarily reducing the chemical substances it releases. Release and transfer amounts of substances subject to Japan's Law concerning Pollutant Release and Transfer Register (PRTR Law) are reported in accordance with the law. In FY2022, chemical substances released into the atmosphere and public waterways totaled 366 tonnes.

Release and Transfer Amounts of PRTR-registered Substances at JFE Steel

*15 JFE Steel consolidated subsidiaries in Japan.

The Japan Iron and Steel Federation formulated a voluntary action plan to reduce VOC emissions by 30% from FY2000 levels by FY2010. As part of this action plan, JFE Steel set a target for reducing emissions to 1,078 tonnes or less. As a result of our initiatives, we achieved a significant reduction that exceeded the 30% reduction target in FY2010 and have been consistently cutting VOC emissions, by more than 50%. Going forward, we will continue to maintain the emissions below 1,078 tonnes and take the necessary steps to prevent any increase.

Emissions of benzene and dichloromethane are kept at low levels. We will continue to set targets for the two substances and maintain low emissions levels.

VOC Emissions

Major chemical substances subject to the PRTR Law for the JFE Engineering works in Tsurumi and Tsu include organic solvents such as xylene used for painting products, manganese and its compounds generated during welding. We report the release and transfer amounts of these substances in accordance with the law.

Release and Transfer Amounts of PRTR-registered Substances at JFE Engineering

*4 JFE Engineering consolidated subsidiaries in Japan.

For more on quantitative data related to PRTR, please refer to the following information.

Environmental DataPCB Waste Management at JFE

Polychlorinated biphenyl (PCB) waste is properly stored and managed at the JFE Group's facilities. High concentration PCB waste is treated in accordance with guidelines set by the Japan Environmental Storage & Safety Corporation (JESCO). The Yokohama Eco Clean Plant of J&T Recycling Corporation treats insulating oil contaminated with slight amounts of PCB, helping to reduce pollutants both in and outside the JFE Group.